Table of Contents

ToggleHazardous Area Classification: Introduction

In industries like oil & gas, chemical processing, refineries, pharmaceuticals, and power plants, safety is not just a priority but it’s a daily responsibility.

These environments deal with flammable gases, vapors and combustible dust, which means the risk of fire and explosion is always present.

One small spark in the wrong place can turn into a major disaster.

This is where Hazardous Area Classification (HAC) becomes critically important. It is the foundation of explosion safety. Without proper hazardous area classification, even the most advanced plant can become unsafe.

Let us understand it in a simple and practical way.

What is Hazardous Area Classification?

Hazardous Area Classification is the systematic process of identifying locations where an explosive atmosphere may occur due to the presence of flammable gases, vapors, or dust. Once these areas are identified, they are divided into zones based on how often and how long the explosive mixture is present.

In simple words, HAC tells us:

1) How dangerous a particular area is?

2) What type of equipment can be safely used there?

3) What protection technique is required?

“Imagine installing a normal electrical motor inside a petrol storage tank. That single decision could cause a massive explosion”

Hazardous area classification prevents such mistakes by guiding engineers toward the right equipment for the right risk level.

Why Hazardous Area Classification is So Important

Many industrial accidents across the world have one common root cause: incorrect equipment selection in hazardous locations. Proper classification directly impacts human safety, equipment life, legal compliance, and plant reliability.

Correct hazardous area classification helps to:

1) Prevent fires and explosions

2) Protect workers and nearby communities

3) Avoid equipment failures and costly shutdowns

4) Meet international safety regulations

5) Reduce insurance and legal risks

From a business perspective, one accident can shut down operations for months. From a human perspective, one accident can change lives forever. That’s why hazardous area classification is taken so seriously in modern industries.

Zone Concept in Hazardous Areas Classification

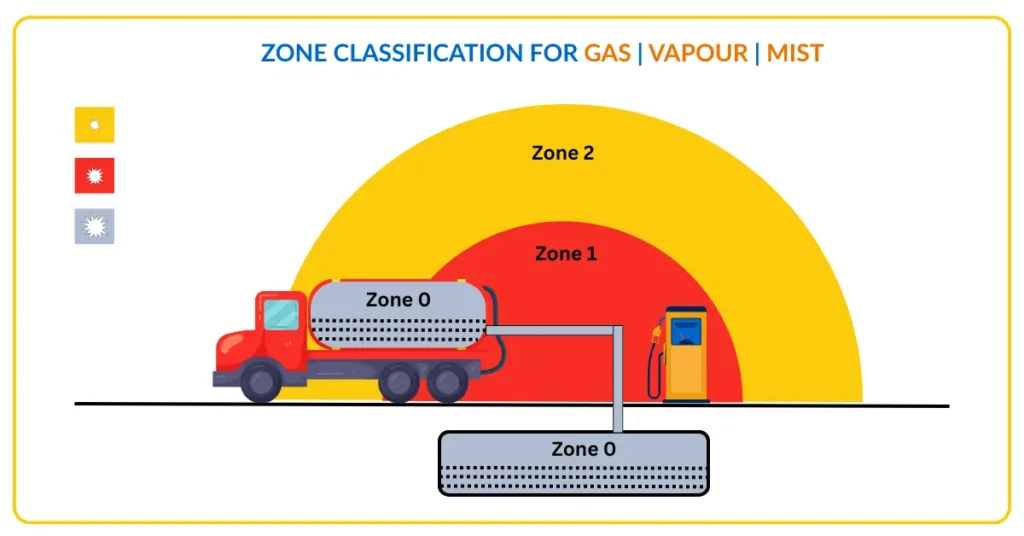

For gas and vapor environments, hazardous locations are divided into three main zones: Zone 0, Zone 1 and Zone 2.

These zones are based on how frequently an explosive atmosphere exists during normal plant operations.

Let us understand each one with examples.

Zone 0 – Where Explosion Risk Is Always Present

Zone 0 is the most dangerous hazardous area.

Here, a flammable gas or vapor is present continuously or for long periods under normal operating conditions. In this zone, the explosive atmosphere is not an exception but it is a part of daily operation.

Typical Zone 0 locations include the inside of fuel storage tanks, process vessels, reactors, and gas pipelines carrying flammable substances.

Because the danger is constant, equipment used in Zone 0 must be intrinsically safe.

This means the device is designed in such a way that it cannot produce enough electrical or thermal energy to ignite the surrounding atmosphere, even if a fault occurs.

If you were allowed to step inside a Zone 0 area (which usually you aren’t during operation), every device around you would be specially designed to work safely in a permanently explosive environment.

Zone 1 – Where Explosive Atmosphere Appears During Normal Operation

Zone 1 areas are those where an explosive atmosphere is likely to occur occasionally during normal plant operation. The gas or vapor is not present all the time, but it appears frequently enough to be considered dangerous.

These areas are commonly found around:

1) Pump seals

2) Valve glands

3) Sampling points

4) Flanges and vent locations

In these places, small leaks can happen during regular process conditions. Even a routine maintenance activity may release flammable vapors into the surrounding area.

Equipment used in Zone 1 must be capable of containing or preventing ignition. Common protection methods include:

1) Flameproof (Ex d) construction

2) Increased safety (Ex e)

3) Intrinsic safety (Ex i)

Zone 1 is where most industrial explosions actually occur, because gas release and ignition sources can exist together during normal operations.

Zone 2 – Where Explosive Atmosphere Is Rare and Short-Lived

Zone 2 is the least dangerous among the hazardous zones, but it is still not a safe zone in the general sense. Here, an explosive atmosphere is not expected during normal operations, and if it does occur, it will only exist for a short period.

This usually happens due to:

1) Abnormal process conditions

2) Accidental equipment failures

3) Temporary ventilation problems

Typical Zone 2 areas include the outer edges of process units, surrounding pipework, and well-ventilated plant sections.

Equipment installed in Zone 2 does not require the same level of heavy protection as Zone 0 or Zone 1, but it must still be non-sparking, properly enclosed, and resistant to accidental ignition.

Many engineers underestimate Zone 2, but history has proven that even rare explosive atmospheres are enough to cause serious accidents if the equipment is wrongly selected.

You can also read our article: Difference Between ATEX and IECEx

Hazardous Area Zones Comparison (Zone 0 vs Zone 1 vs Zone 2)

| Parameter | Zone 0 | Zone 1 | Zone 2 |

|---|---|---|---|

| Gas Presence | Present continuously or for long periods | Likely to occur during normal operation | Not expected during normal operation, only short time |

| Risk Level | Extremely high | High | Moderate |

| Gas Exposure Duration | Constant | Intermittent | Rare |

| Typical Equipment Allowed | Intrinsically Safe (Ex ia) only | Flameproof (Ex d), Increased Safety (Ex e), Intrinsically Safe | Non-sparking, protected equipment |

| Probability of Explosion | Always possible | Frequently possible | Unlikely but still possible |

| Typical Locations | Inside tanks, pipelines, reactors, vessels | Around pump seals, valve glands, vent points, sampling stations | Outer process areas, pipe racks, well-ventilated spaces |

| Ventilation Requirement | Usually not effective (gas always present) | Important for risk reduction | Very important to prevent buildup |

| Maintenance Restrictions | Very strict | Strict | Moderate |

| Equipment Certification Level | Highest | High | Basic hazardous protection |

| Example | Inside petrol storage tank | Area near a refinery pump | Open area near pipeline corridor |

Frequently Asked Questions (FAQs)

1. What is the main purpose of Hazardous Area Classification?

The main purpose of hazardous area classification is to identify locations where explosive gases or vapors may be present and ensure that only certified, safe equipment is installed in those areas to prevent fires and explosions.

2. What is the difference between Zone 0, Zone 1, and Zone 2?

- Zone 0: Explosive gas is present continuously or for long periods.

- Zone 1: Explosive gas is likely to occur during normal operation.

- Zone 2: Explosive gas is not expected during normal operation and appears only briefly during abnormal conditions.

3. Which type of equipment is allowed in Zone 0?

Only intrinsically safe (Ex ia) equipment or specially certified devices that cannot generate ignition energy are allowed in Zone 0 because the explosive atmosphere is always present.

4. Who is responsible for doing Hazardous Area Classification in a plant?

Hazardous Area Classification is carried out by qualified safety, electrical, and instrumentation engineers using international standards such as IEC, ATEX, or NEC.

5. Is Hazardous Area Classification mandatory by law?

Yes. In most countries, hazardous area classification is legally required for plant approval, insurance coverage, and regulatory compliance, especially in industries handling flammable substances.

6. Can normal electrical equipment be used in Zone 2?

No. Even in Zone 2, standard electrical equipment without protection is not allowed. Equipment must be non-sparking, properly enclosed, and certified for hazardous locations.

7. What happens if hazardous area classification is ignored?

Ignoring hazardous area classification can lead to equipment ignition, major fires, plant explosions, legal penalties, financial losses, and loss of human life. It is one of the most common root causes of industrial accidents.