Table of Contents

ToggleConditioning Orifice Plate and Standard Orifice Plate: Introduction

Orifice plates are one of the most widely used primary elements for flow measurement in industrial piping systems. Their popularity comes from a simple construction, proven measurement theory, and long acceptance in international standards.

However, not all orifice plates behave the same way once they are installed in real plants.

Two commonly used designs are the Standard Orifice Plate and the Conditioning Orifice Plate (COP).

Although both work on the principle of differential pressure, their performance differs significantly when it comes to flow disturbances, installation space, and measurement reliability.

Understanding this difference is critical for selecting the right solution for your application.

What is a Standard Orifice Plate?

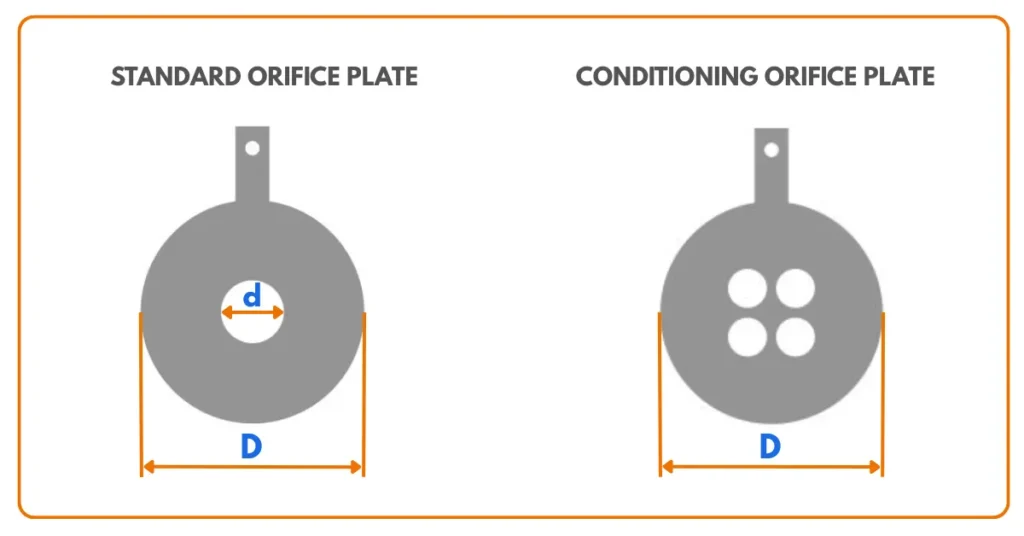

A Standard Orifice Plate is the most traditional and widely used primary element for differential pressure flow measurement. It consists of a flat metal plate with a single, sharp-edged concentric hole installed between pipe flanges.

The pressure drop generated across the plate is directly related to the flow rate of the fluid. Standard Orifice Plates rely heavily on long upstream and downstream straight pipe lengths to ensure a fully developed and symmetrical flow profile.

When installed under proper conditions and in compliance with standards such as ISO 5167, they offer reliable and repeatable measurements, especially in applications where space is not a constraint and strict standards compliance is required.

What is a Conditioning Orifice Plate (COP)?

A Conditioning Orifice Plate (COP) is a specially designed differential pressure flow element that combines flow restriction and flow conditioning in a single plate.

Instead of one central bore, it uses multiple small holes arranged symmetrically across the plate. This design helps break up swirl, turbulence, and uneven velocity profiles created by upstream piping disturbances such as elbows, valves, or pumps.

As a result, the flow becomes more uniform as it passes through the plate, allowing accurate flow measurement even when straight pipe lengths are limited.

Conditioning Orifice Plates are commonly used in compact piping systems, skid-mounted equipment, and retrofit installations where ideal straight-run conditions cannot be achieved.

Understanding the Basic Design Difference

A Standard Orifice Plate is a flat metal plate with a single, sharp-edged concentric bore. When fluid flows through this restriction, a pressure drop is created, which is then used to calculate the flow rate.

A Conditioning Orifice Plate looks similar at first glance, but instead of one central hole, it contains multiple smaller holes arranged symmetrically across the plate.

This multi-hole design allows the plate to act as both:

A flow restriction

A built-in flow conditioner

This fundamental design difference strongly influences how each plate behaves in disturbed flow conditions.

Effect of Flow Disturbances on Measurement

In an ideal installation, the flow approaching an orifice plate should have a fully developed and symmetrical velocity profile. Unfortunately, real piping systems rarely offer ideal conditions.

Upstream components such as:

Elbows

Tees

Control valves

Pumps

Reducers

introduce swirl, turbulence, and uneven velocity distribution.

A Standard Orifice Plate is highly sensitive to these disturbances. If the flow is not fully developed, the differential pressure measured across the plate no longer represents the true flow rate, leading to measurement errors.

A Conditioning Orifice Plate is designed specifically to handle such disturbed flow. The multiple holes break up swirl and redistribute velocity, helping the flow reorganize before passing through the restriction.

Straight Pipe Length Requirement

Straight pipe length is one of the most important installation criteria for any differential pressure flow element.

For a Standard Orifice Plate, long straight runs are essential. Depending on the upstream disturbance, typical requirements can range from:

10D to 50D upstream

Around 5D downstream

These long straight lengths allow the velocity profile to stabilize before reaching the plate.

A Conditioning Orifice Plate significantly reduces this requirement. In many practical installations, straight lengths as short as:

2D upstream

2D downstream

are sufficient.

This makes Conditioning Orifice Plates especially attractive for skid-mounted systems, packaged equipment, and retrofit projects where space is limited.

Accuracy Under Real Plant Conditions

In laboratory conditions with perfect piping geometry, Standard Orifice Plates can achieve very high accuracy.

However, real plants rarely provide such ideal conditions. Small deviations in straight pipe length, upstream layout, or alignment can noticeably affect measurement accuracy.

Conditioning Orifice Plates are far more tolerant of real-world installations. Even when installed close to elbows or valves, they can maintain stable and repeatable measurements.

This makes them a preferred choice for applications where piping constraints cannot be avoided.

Beta Ratio and Flow Range Considerations

Standard Orifice Plates offer a wide range of beta ratios, typically from 0.1 to 0.75. This flexibility allows engineers to optimize measurement accuracy for specific flow ranges and pipe sizes.

Conditioning Orifice Plates usually come with predefined beta ratios, commonly around 0.4 and 0.65, independent of pipe schedule.

While this limits customization, it simplifies selection, reduces engineering effort, and minimizes the risk of incorrect sizing.

Installation Sensitivity and Alignment

Accurate installation is critical for Standard Orifice Plates. Errors such as:

Poor centering

Incorrect gasket placement

Plate eccentricity

can introduce additional uncertainty into the measurement.

Conditioning Orifice Plates are generally more forgiving. Their symmetrical hole pattern and centering rings help reduce sensitivity to minor installation imperfections.

This improves measurement reliability, especially in field installations.

Performance in Wet Gas and Condensate Applications

In wet gas or multiphase applications, liquid accumulation can become a serious issue.

A Standard Orifice Plate, with its single central bore, can allow condensate to build up upstream of the plate. This can cause fluctuating readings and long-term operational problems.

Conditioning Orifice Plates allow liquids to pass through multiple openings, reducing the chance of condensate buildup and improving stability in such applications.

Standards and Compliance Considerations

Standard Orifice Plates are fully defined in international standards such as ISO 5167, including dimensional requirements, tolerances, and calculation methods.

Conditioning Orifice Plates are not strict dimensional copies of ISO 5167 plates. Instead, they are designed based on industry guidelines, experimental validation, and manufacturer-specific testing.

For regulated or custody transfer applications, this difference should always be reviewed carefully with the end user and governing standards.

Inventory, Maintenance, and Lifecycle Impact

Standard Orifice Plate systems often require multiple plates for different beta ratios and operating conditions. This increases spare inventory and storage requirements.

Conditioning Orifice Plates reduce inventory complexity due to their fixed bore configurations and wider operating range.

Both designs are passive devices with minimal maintenance requirements, making them robust long-term solutions.

Cost and Overall Project Economics

When comparing costs, it is important to look beyond the price of the plate itself.

Standard Orifice Plates may appear inexpensive initially, but long straight pipe runs, additional piping, and flow conditioners can significantly increase total installed cost.

Conditioning Orifice Plates reduce piping length, installation time, and auxiliary components, often resulting in lower overall project cost, particularly in brownfield and skid-based installations.

Typical Application Areas

Standard Orifice Plates are commonly selected when:

Long straight pipe runs are available

Strict standards compliance is required

Custody transfer applications are involved

Conditioning Orifice Plates are well suited for:

Space-constrained piping systems

Skid-mounted and packaged equipment

Retrofit and revamp projects

Cpmparision: Conditioning Orifice Plate vs. Standard Orifice Plate

| Parameter | Conditioning Orifice Plate (COP) | Standard Orifice Plate |

|---|---|---|

| Bore Configuration | Multiple (4) circular bores arranged symmetrically across the plate | Single concentric bore at the center |

| Beta Ratio Availability | Limited to predefined beta ratios (typically 0.4 and 0.65), independent of pipe schedule | Wide range of beta ratios (≈0.1 to 0.75), selected based on pipe size and schedule |

| Flow Conditioning Capability | Integrated flow conditioning achieved through multi-hole geometry | No inherent conditioning; external straighteners or long straight runs required |

| Straight Pipe Length Needed | Very short runs: typically 2D upstream and 2D downstream | Long straight lengths needed: typically 10–50D upstream and 5D downstream |

| Plate Construction | Thicker construction compared to conventional plates, improving rigidity | Thickness governed by standards; thinner plates may flex at high DP |

| Accuracy in Real Installations | Maintains good accuracy even with disturbed upstream flow | Accuracy degrades significantly with upstream disturbances |

| Installation Sensitivity | Less sensitive to alignment errors due to centering ring design | Highly sensitive to eccentricity and angular misalignment |

| Condensate Behavior | Multi-hole design allows liquids to pass through without accumulation | Central bore may trap condensate, especially in wet gas services |

| Standards Compatibility | Designed in line with ISO 5167 and ASME MFC guidelines | Fully compliant with ISO 5167 dimensional requirements |

| Spare & Inventory Needs | Reduced inventory due to fixed bore and beta configurations | Larger inventory required for different beta ratios and pipe schedules |

| Typical Applications | Skid-mounted systems, compact installations, space-constrained piping | Large installations with sufficient straight pipe availability |

| Overall Installation Cost | Lower total cost due to reduced piping and no flow conditioners | Higher total cost because of additional piping and accessories |

FAQs: Conditioning Orifice Plate vs Standard Orifice Plate

1. What is the main difference between a Conditioning Orifice Plate and a Standard Orifice Plate?

The main difference lies in how they handle disturbed flow. A Standard Orifice Plate uses a single central bore and depends on long straight pipe lengths for accuracy, while a Conditioning Orifice Plate uses multiple holes to condition the flow internally, allowing accurate measurement even with limited straight pipe lengths.

2. Why does a Conditioning Orifice Plate require shorter straight pipe lengths?

A Conditioning Orifice Plate redistributes velocity and reduces swirl using its multi-hole design. This internal flow conditioning minimizes the effect of upstream disturbances, reducing the need for long straight runs before and after the plate.

3. Can Conditioning Orifice Plates replace Standard Orifice Plates in all applications?

No. While Conditioning Orifice Plates are ideal for space-constrained installations, Standard Orifice Plates are still preferred in applications requiring strict compliance with ISO 5167, such as custody transfer or regulated measurements.

4. Are Conditioning Orifice Plates suitable for wet gas or multiphase flow?

Yes. Conditioning Orifice Plates handle wet gas and condensate better than Standard Orifice Plates because liquids can pass through multiple openings, reducing the risk of liquid buildup and unstable readings.

5. Which orifice plate is more accurate in real plant installations?

In real-world installations with piping disturbances, Conditioning Orifice Plates generally provide more stable and repeatable accuracy.

Standard Orifice Plates perform best only when ideal straight pipe lengths and installation conditions are met.

6. Do Conditioning Orifice Plates follow international standards?

Standard Orifice Plates are fully defined by ISO 5167. Conditioning Orifice Plates are designed based on industry guidelines and manufacturer validation but may not meet all dimensional requirements of ISO 5167. This should be reviewed for critical applications.

7. How do installation costs compare between Conditioning and Standard Orifice Plates?

Although both plates may have similar initial costs, Standard Orifice Plate installations often require additional piping and accessories.

Conditioning Orifice Plates usually result in lower total installed cost due to reduced straight pipe requirements.

Conclusion

Both Conditioning Orifice Plates and Standard Orifice Plates are proven flow measurement technologies, but they address different installation realities.

A Standard Orifice Plate remains a reliable choice when piping conditions are ideal and standards compliance is the primary requirement.

A Conditioning Orifice Plate offers clear advantages when space is limited, flow is disturbed, and installation flexibility is essential.

Selecting the right orifice plate is not just about calculation it is about understanding how real piping systems behave in the field.

I hope you like above blog. There is no cost associated in sharing the article in your social media. Thanks for Reading !! Happy Learning