Table of Contents

ToggleIf you have ever connected a PLC to a VFD, an energy meter, a temperature controller, or even a simple weighing indicator, you must have seen two common communication options: RS232 and RS485.

Both are called serial communication, but in real plant conditions they behave very differently. Choosing the wrong one can lead to unstable data, random communication faults, and lots of troubleshooting time.

RS232 is mainly for short and direct connections, while RS485 is made for long-distance and multi-device industrial networks.

That is the basic idea behind RS232 vs RS485. Now let us understand why this difference exists.

What RS232 and RS485 actually mean?

RS232 and RS485 are electrical interface standards. They define how electrical signals are sent on wires, not how the data itself is structured.

They mainly define:

Voltage levels used for communication

How signals are referenced to ground

How many devices can connect on the same line

How far the signal can travel reliably

Protocols like Modbus RTU, ASCII, or proprietary PLC protocols run on top of RS232 or RS485.

So when we talk about RS232 vs RS485, we are talking about the physical layer, not the software protocol.

Communication structure and number of devices

One of the biggest differences between RS232 vs RS485 is how many devices can talk on the same cable.

RS232 communication structure

Point-to-point only – one transmitter and one receiver

Only two devices can communicate directly

Not suitable for networking multiple field devices

This is why RS232 is mostly used between a PC and one instrument, or between two devices located very close to each other.

RS485 communication structure

Multi-drop network – one master can communicate with many slaves

Several devices can share the same communication line

Ideal for field-level networks such as Modbus RTU

This makes RS485 perfect for connecting multiple meters, drives, and controllers on a single cable in industrial automation.

Signal type and noise immunity

Industrial plants are full of electrical noise from motors, contactors, and variable frequency drives. This is where RS232 vs RS485 becomes very important.

RS232 signal behavior

Uses single-ended signaling

Signal is measured with respect to ground

Any ground noise or voltage shift can disturb the signal

Because of this, RS232 works well only in clean electrical environments and short distances.

RS485 signal behavior

Uses differential signaling with two opposite polarity wires

Receiver reads the voltage difference between the two wires

Noise affecting both wires gets cancelled out

This is why RS485 is much more resistant to EMI and is preferred in harsh industrial environments.

Communication distance capability

Distance is another practical factor when comparing RS232 vs RS485.

RS232 distance limitations

Designed for short cable runs

Typically reliable up to around 10 to 15 meters

Longer distances increase error probability

RS485 distance capability

Designed for long cable runs

Can reach several hundred meters and even more with proper wiring

Works well in large plants and outdoor installations

So if your instrument is installed far from the control panel, RS485 is almost always the better choice.

Wiring complexity and cable requirement

Wiring may look simple, but it plays a huge role in communication stability.

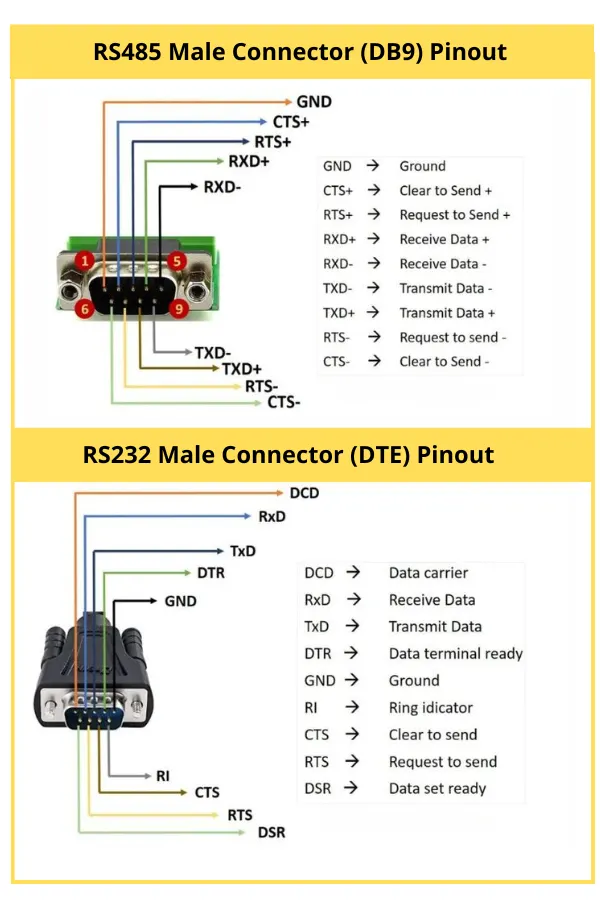

RS232 wiring characteristics

Requires separate transmit and receive lines

Needs common ground reference

Often uses DB9 connectors or multi-core cables

RS485 wiring characteristics

Usually uses only one twisted pair for data

Supports daisy-chain wiring between devices

Screw terminals are common in industrial instruments

This is why RS485 networks are easier to expand and maintain in field installations.

Duplex communication behavior

Another technical but important difference in RS232 vs RS485 is how data flows.

RS232 communication mode

Full duplex by default

Sending and receiving can happen at the same time

Separate wires for transmit and receive

RS485 communication mode

Can be full duplex or half duplex

Most industrial networks use half duplex

Only one device transmits at a time

This is why proper protocol timing is important in RS485 networks to avoid data collisions.

Termination and network stability

This is one area where many field engineers face trouble with RS485.

RS232 termination behavior

No termination resistors required

Simple point-to-point wiring

RS485 termination requirement

Termination resistors are needed at both ends of the cable

Prevents signal reflection on long cables

Bias resistors may be needed to avoid floating lines

In RS232 vs RS485, RS485 gives better performance but needs more care in wiring practices.

Typical industrial applications

Understanding where each standard is used makes the RS232 vs RS485 difference very clear.

Where RS232 is commonly used

Laptop to PLC or instrument for configuration

Printer or display connected to one controller

Short internal panel connections

Where RS485 is commonly used

Modbus RTU networks in plants

Multiple energy meters connected to SCADA

VFD and temperature controller networks

Remote field devices over long cable distances

That is why most industrial communication networks prefer RS485.

Selection guide for engineers and technicians

If you are selecting communication for a new project, keep this simple logic in mind.

If there is only one device and the cable is short, RS232 is sufficient.

If there are many devices on one line, RS485 is required.

If the environment has electrical noise, RS485 is safer.

If the distance is more than a few meters, RS485 is the better choice.

In industrial automation, this rule solves most RS232 vs RS485 selection problems.

Common mistakes seen in RS485 installations

Even though RS485 is strong, wrong installation can create problems.

Star topology instead of proper daisy-chain wiring

Missing termination resistors at cable ends

Wrong A and B line polarity connections

Running communication cable together with power cables

No proper grounding reference in long networks

Most communication failures blamed on devices are actually wiring issues.

What we learn today?

Both RS232 and RS485 are useful, but they are designed for different purposes. RS232 is simple, direct, and suitable for short links. RS485 is designed for industrial networking, long distances, and noisy environments.

So when choosing between RS232 vs RS485, think about distance, number of devices, and plant conditions. In most industrial automation systems, RS485 becomes the natural and safer choice for stable communication.

I hope you like above blog. There is no cost associated in sharing the article in your social media. Thanks for Reading !! Happy Learning