Table of Contents

ToggleWheatstone Bridge: Introduction

A Wheatstone Bridge is an electrical measurement circuit used to determine an unknown resistance by comparing it against known resistances arranged in a bridge configuration.

The circuit consists of two voltage-divider paths, often called the legs of the bridge. When the resistance values are correctly balanced, the voltage difference between the two midpoints becomes zero, and no current flows through the measuring device.

This null-balance principle allows very small resistance changes to be detected with high accuracy, which is why Wheatstone bridges are widely used in pressure sensors, strain gauges, load cells, and other precision instrumentation applications.

Circuit Configuration of a Wheatstone Bridge

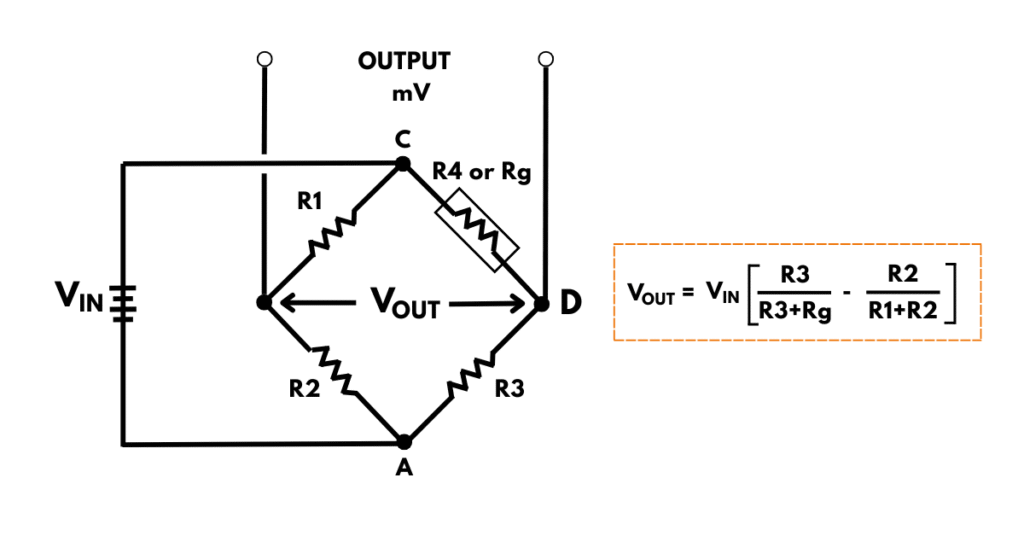

A Wheatstone bridge is built using a simple but highly effective electrical arrangement that allows precise resistance comparison. The circuit is arranged in a bridge or diamond shape, with each element having a specific role in achieving balance and accuracy.

1. Four Resistors Forming the Bridge

The core of the Wheatstone bridge consists of four resistors connected in a closed loop, forming a diamond-shaped network. These resistors are divided into two parallel paths, often referred to as the left and right legs of the bridge.

2. Known Resistances (R1 and R2)

R1 and R2 are fixed, known resistance values placed in two arms of the bridge. Their purpose is to establish a reference ratio against which the unknown resistance is compared. In practical instrumentation circuits, these resistors are precision-grade components with low temperature drift.

3. Adjustable Resistance (R3)

R3 is a variable resistor used to balance the bridge. By adjusting R3, the voltage difference between the bridge midpoints can be driven to zero. In laboratory setups, this is done manually, while in industrial transmitters the adjustment is achieved electronically.

4. Unknown Resistance (R4 or Rg)

R4, sometimes labeled as Rg, represents the unknown resistance to be measured. In instrumentation applications, this element is often a sensor such as a strain gauge, pressure sensor element, or load cell whose resistance changes with physical input.

5. DC Excitation Voltage (VIN)

A stable DC voltage source is applied across opposite corners of the bridge, typically between points A and C. This excitation voltage energizes the bridge and enables measurable voltage differences to develop when the bridge becomes unbalanced.

6. Measuring Instrument Between Bridge Midpoints

A galvanometer or high-impedance voltmeter is connected between the center nodes of the bridge, commonly labeled B and D. When the bridge is perfectly balanced, the voltage across this instrument is zero. Any change in the unknown resistance causes an imbalance, producing a measurable output voltage.

How Does a Wheatstone Bridge Work?

A Wheatstone bridge works by comparing two pairs of resistances and checking whether the bridge is in balance or not. This balance condition decides how the unknown resistance is detected.

1. Balanced Bridge – Zero Output Condition

When the resistance ratio in one leg of the bridge matches the ratio in the other leg, the bridge is balanced. In this state, the voltage at both midpoints is equal, so no current flows through the measuring device.

This zero-output condition allows the unknown resistance to be calculated accurately using simple ratios.

2. Unbalanced Bridge – Measurement Mode

When the resistance ratios change, the bridge becomes unbalanced. This creates a small voltage difference between the midpoints, causing current to flow through the measuring circuit.

The size and direction of this voltage indicate how much the unknown resistance has changed.

In real instrumentation systems, the bridge usually operates in this unbalanced mode so that even tiny resistance changes caused by pressure, force, or temperature can be continuously measured.

Bridge Configurations

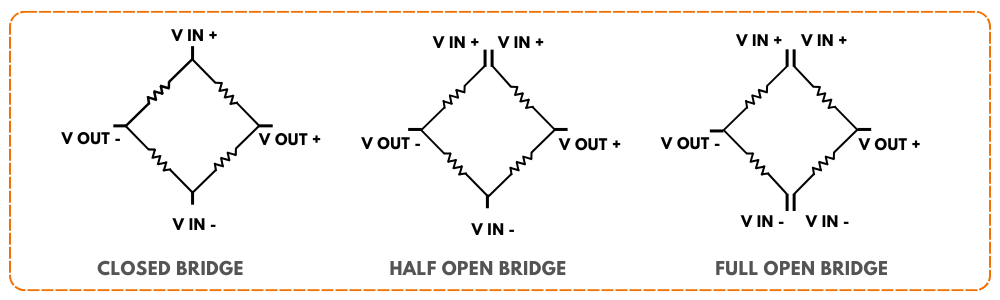

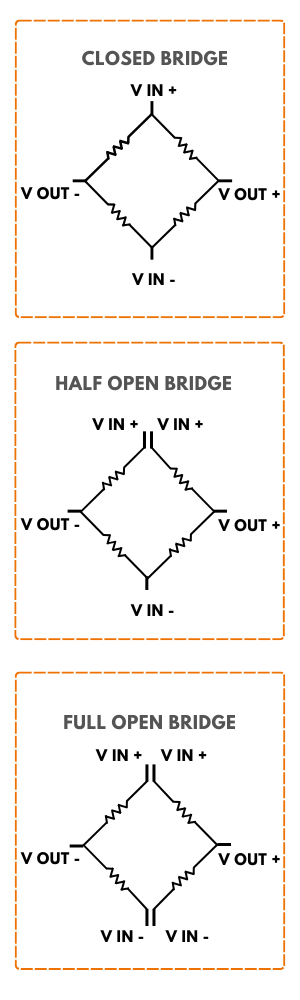

Depending on how the resistors are interconnected, a Wheatstone bridge can be configured in different ways. Each configuration has practical implications for measurement, calibration, and signal conditioning.

1. Closed Bridge Configuration

In a closed bridge, all four resistors are fully connected, forming a complete loop. Because each resistor is electrically influenced by the other three, individual resistance values cannot be measured directly.

This configuration is commonly used when the bridge functions as a complete sensor element and individual resistor diagnostics are not required.

2. Half-Open Bridge Configuration

A half-open bridge is split into two branches that are connected at one end. Unlike a closed bridge, this arrangement allows each resistor to be measured individually, which is useful when evaluating sensor performance or drift.

The half-open configuration also allows the addition of active or passive compensation techniques. One additional electrical connection is required compared to a closed bridge.

3. Full-Open Bridge Configuration

In a full-open bridge, the circuit is divided into two separate branches that are open at both ends. This configuration allows individual measurement of each resistor and supports both active and passive compensation methods.

An added advantage is that each half of the bridge can be powered and measured independently, which suits certain signal conditioners used in pressure sensor applications. However, this configuration requires more electrical connections than a half-open bridge.

Why Strain Gauges Need Wheatstone Bridge Circuits

A strain gauge measures mechanical deformation by producing a very small change in electrical resistance. On its own, this resistance change is too small to be measured accurately, especially in industrial environments.

A Wheatstone bridge solves this problem by converting tiny resistance changes into a measurable voltage output. When a strain gauge is placed in one or more arms of the bridge, applied strain unbalances the circuit and creates a proportional voltage signal that can be amplified and measured.

Different bridge arrangements quarter bridge, half bridge, and full bridge are used to improve sensitivity and accuracy. Full-bridge configurations also help cancel temperature effects and other external influences.

This is why Wheatstone bridge circuits are standard in load cells, pressure sensors, and structural monitoring systems.

Applications of a Wheatstone Bridge

The Wheatstone bridge is widely used in instrumentation because it converts very small resistance changes into measurable electrical signals. This makes it ideal for sensors that respond to physical parameters rather than direct electrical inputs.

1. Resistance Measurement

The original and most basic use of a Wheatstone bridge is accurate measurement of an unknown resistance. By balancing the bridge using known resistors, the unknown resistance can be calculated with high precision.

2. Strain Measurement (Strain Gauges)

In strain gauges, mechanical deformation causes a minute change in resistance. A Wheatstone bridge detects this small change reliably, which is why it is used in load cells, force sensors, and structural monitoring systems.

3. Temperature Measurement

Temperature sensors such as thermistors and RTDs change resistance with temperature. When connected in a Wheatstone bridge, these small resistance variations are converted into a measurable voltage signal.

4. Pressure Measurement

Most pressure transmitters use a Wheatstone bridge internally. Pressure applied to a sensing diaphragm changes the resistance of strain elements, and the bridge converts this change into an electrical output.

5. Level Measurement

In certain level measurement techniques, mechanical movement or sensor deformation changes resistance. A Wheatstone bridge helps translate this resistance change into a usable signal for level indication.

6. Gas Detection Sensors

Some gas sensors rely on resistance changes when exposed to specific gases. The Wheatstone bridge detects these changes, allowing gas concentration to be measured accurately.

7. Medical Instrumentation

Medical devices such as ECG and EEG systems use Wheatstone bridge concepts to detect very small bio-electrical signal variations with high sensitivity.

8. Industrial Automation Systems

In industrial automation, Wheatstone bridges are used inside transmitters and sensors to monitor pressure, temperature, force, and strain with stability and repeatability.

9. Robotics and Mechatronics

Robotic systems use Wheatstone bridge-based sensors to measure force, torque, and position, helping robots respond accurately to physical interactions.

10. Automotive Sensors

Automotive sensors such as pressure, load, and temperature sensors rely on Wheatstone bridge circuits to ensure reliable measurements under harsh operating conditions.

I hope you like above blog. There is no cost associated in sharing the article in your social media. Thanks for Reading !! Happy Learning