Table of Contents

ToggleWhat Is Sensor Linearity and What Does It Mean?

In instrumentation and measurement systems, sensors are expected to convert a physical quantity into an electrical signal as accurately and predictably as possible.

Whether the sensor is measuring pressure, temperature, flow, level or displacement, engineers rely on the sensor output to represent the actual process condition. One of the most important parameters that defines this behavior is Sensor Linearity.

Sensor-Linearity is often mentioned in datasheets, but it is also one of the least understood specifications. Many engineers look only at accuracy or range and overlook how linear the sensor response really is.

This article explains Sensor-Linearity and shows why it directly affects calibration, scaling, and measurement uncertainty.

Understanding Sensor Linearity

Sensor-Linearity describes how closely a sensor’s output follows a straight-line relationship with its input over the entire measurement range.

In an ideal sensor:

A proportional increase in input produces a proportional increase in output

The input–output relationship forms a perfect straight line

Calibration becomes simple and predictable

In real sensors, this ideal condition never exists. Small deviations always occur, and these deviations are described as Sensor Linearity error or non-linearity.

What Is Sensor Linearity Error or Non-Linearity?

Sensor-Linearity error is defined as the maximum deviation of the actual sensor output from a reference straight line, measured under constant environmental conditions.

This deviation is not noise or random fluctuation. It is a systematic difference between the expected output and the actual output of the sensor.

To understand this clearly:

Known input values are applied across the full sensor range

The corresponding output values are recorded

A straight reference line is selected

The largest deviation from this line is taken as the Sensor Linearity error

The smaller this deviation, the better the Sensor Linearity.

Why the Reference Straight Line Is Important

Sensor-Linearity cannot be defined without first defining the reference straight line. Different reference lines can produce different linearity values for the same sensor.

Common reference lines include:

End-point straight line

Zero-based straight line

Best Fit Straight Line (BFSL)

Among these, the Best Fit Straight Line is the most widely accepted and practically meaningful method.

Best Fit Straight Line and Sensor Linearity

The Best Fit Straight Line is calculated using the least squares method, which minimizes the total squared deviation between all measured data points and the straight line.

This method is preferred because:

It represents the overall sensor behavior, not just the endpoints

Positive and negative deviations are balanced

It reflects real-world performance during normal operation

Most reputable sensor manufacturers specify Sensor-Linearity error with respect to the Best Fit Straight Line because it provides a realistic and statistically sound representation of sensor performance.

Why Sensor Linearity Matters in Calibration

Sensor-Linearity is very important during calibration and scaling.

When Sensor Linearity is good:

A simple linear scaling equation is sufficient

Fewer calibration points are required

Measurement uncertainty is reduced

When Sensor Linearity is poor:

Multi-point calibration becomes necessary

Software linearization may be required

Errors increase at mid-range values

In control systems, poor Sensor-Linearity can lead to incorrect control action even if the sensor appears accurate at the calibration points.

Interaction of Sensor Linearity with Other Errors

Sensor-Linearity does not exist in isolation. Several other error sources influence the final measurement result.

To correctly interpret a Sensor Linearity specification, the following conditions must be satisfied:

Stable environmental conditions

Temperature, humidity, and vibration must be controlled. Thermal drift can easily mask linearity effects.Good repeatability

The sensor must give the same output for the same input every time. Poor repeatability makes Sensor Linearity meaningless.Low hysteresis

The output should not depend on whether the input is increasing or decreasing. Hysteresis often appears as false non-linearity.Linear signal conditioning electronics

Amplifiers, ADCs, and transmitters must have negligible non-linearity compared to the sensor.Adequate resolution

The sensor and readout resolution must be fine enough to detect small deviations caused by Sensor Linearity error.

Why Sensor Errors Cannot Be Added Directly

Measurement errors are often misunderstood. Sensor-Linearity error cannot simply be added to other errors.

Instead, uncertainties are combined using the Root-Sum-Squares (RSS) method.

This means:

Each error contributes based on its magnitude

Large errors dominate the total uncertainty

Improving Sensor Linearity alone may not improve accuracy if other errors are larger

This is why system-level accuracy analysis is essential, not just sensor-level specifications.

How Sensor Linearity Is Specified

Sensor-Linearity is usually expressed as a percentage of output span.

For unipolar sensors:

Linearity is specified as ± % of Full Scale Output (FSO)

For bipolar sensors:

Linearity is specified as ± % of Full Range Output (FRO)

This includes both positive and negative output ranges

Understanding this distinction is important when comparing different sensor datasheets.

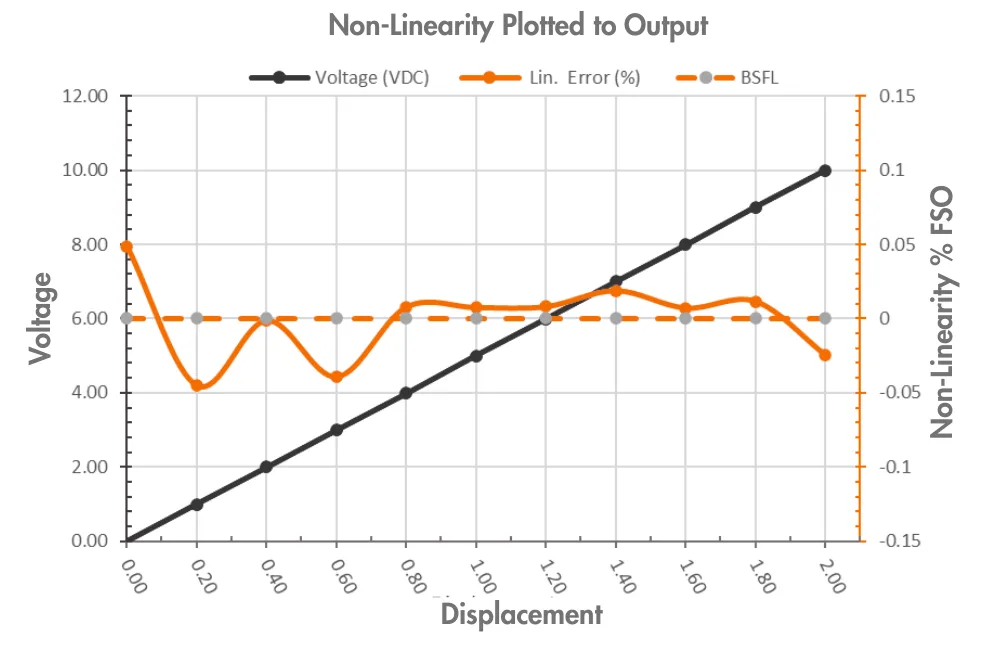

Practical Example of Sensor Linearity

Consider a displacement sensor with:

Measurement range: 0 to 2 inches

Output signal: 0 to 10 V DC

Sensor Linearity error: ±0.25 % of FSO

Now analyze the effect:

Full Scale Output = 10 V

Linearity error = ±25 mV

Scale factor = 5 V per inch

Equivalent displacement error = ±0.005 inches

This example shows how Sensor Linearity directly translates into real measurement error that must be evaluated against application requirements.

What we learn today?

Sensor Linearity is not just a datasheet number but it directly influences how reliable and predictable a measurement system will be in real operation.

A sensor with good Sensor Linearity makes calibration easier, reduces scaling errors, and improves confidence in the measured values across the entire range.

At the same time, Sensor Linearity must always be viewed along with other error sources such as temperature effects, repeatability, hysteresis, and resolution, since measurement uncertainty is the combined result of all these factors.

By understanding Sensor Linearity properly and evaluating it in the context of the complete measurement system, engineers can select the right sensor, design better calibration strategies, and achieve more accurate and stable process measurements over the long term.

I hope you like above blog. There is no cost associated in sharing the article in your social media. Thanks for Reading !! Happy Learning