Table of Contents

TogglePressure instruments such as gauges and transmitters are often installed directly on process lines. Under normal conditions, this works well. But in many industrial environments, the process media or operating conditions are far from ideal. High temperature, corrosive chemicals, viscous fluids, or frequent clogging can quickly damage pressure instruments and lead to inaccurate readings or early failure.

This is where a diaphragm seal becomes a critical accessory. It allows pressure to be measured safely and reliably, even when the process conditions are harsh or incompatible with the measuring instrument.

In this article, we explain diaphragm working principle, why they are used and where they are commonly applied suitable for engineers, technicians, and students.

What Is a Diaphragm Seal?

A diaphragm seal is a mechanical isolation device installed between the process and a pressure measuring instrument.

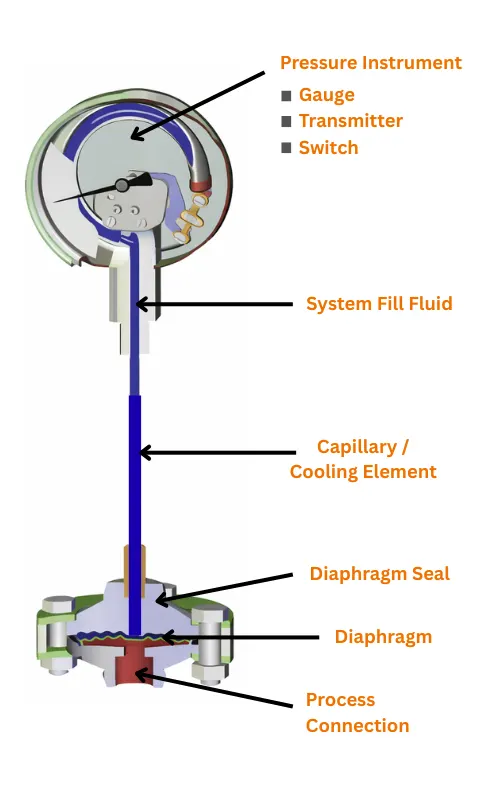

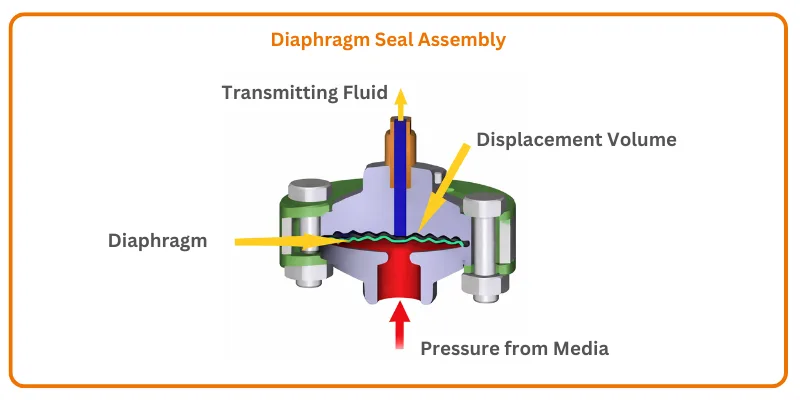

It consists of a thin, flexible metallic diaphragm that directly contacts the process media. Behind this diaphragm is a sealed cavity filled with a system (fill) fluid. When the process pressure acts on the diaphragm, the diaphragm deflects and transmits the pressure hydraulically through the fill fluid to the pressure gauge, pressure transmitter, or pressure switch.

In simple words, the diaphragm seal:

Separates the process media from the pressure instrument

Transfers pressure accurately without allowing direct contact

Basic Working Principle of a Diaphragm Seal

The working principle of a diaphragm seal is purely mechanical and hydraulic.

Process pressure acts on the exposed diaphragm surface

The diaphragm flexes proportionally to the applied pressure

The sealed fill fluid transfers this pressure to the measuring element

The pressure instrument displays or transmits the corresponding value

Corrugations on the diaphragm increase its effective surface area. This improves sensitivity and ensures accurate pressure transmission, especially at low-pressure ranges.

Because the process media never enters the instrument, the internal sensing element remains clean, protected, and stable over time.

Why Diaphragm-Seals Are Used in Pressure Measurement

Direct mounting of pressure instruments is not always practical or safe. Diaphragm seals are used whenever process conditions can harm the instrument or affect measurement reliability.

1. Protection Against Aggressive Media

Many industrial fluids are corrosive, toxic, abrasive, or chemically incompatible with standard instrument materials. The diaphragm acts as a protective barrier.

2. Prevention of Clogging and Solidification

Viscous, sticky, or crystallizing media can clog pressure ports and impulse lines. A diaphragm seal eliminates internal cavities where deposits can build up.

3. High and Low Temperature Isolation

Extreme temperatures can damage pressure sensors or distort readings. Diaphragm seals allow the instrument to be isolated or remotely mounted away from heat or cold.

4. Improved Instrument Lifetime

By isolating the sensing element from harsh conditions, diaphragm seals significantly extend the service life of pressure gauges and transmitters.

5. Measurement in Difficult Installations

When space is limited or the process connection is awkward, diaphragm seals enable flexible mounting options, including remote installation with capillaries.

Key Benefits of Using a Diaphragm-Seal

A properly selected diaphragm-seal offers multiple operational advantages.

Improved safety when handling hazardous or toxic media

Reduced maintenance and cleaning requirements

Stable and repeatable pressure measurements

Protection against corrosion and erosion

Compatibility with demanding industrial environments

Importantly, when engineered correctly, a diaphragm seal introduces minimal measurement error while providing maximum protection.

Diaphragm Seal with Capillary – Remote Mounting

In many applications, the pressure instrument cannot be mounted directly at the process connection.

A diaphragm seal can be connected to the instrument using a capillary tube filled with system fluid.

This arrangement allows:

Remote mounting of the pressure instrument

Protection from vibration, heat, or ambient extremes

Easier access for reading, calibration, or maintenance

Capillary length, diameter, and routing must be carefully selected to minimize temperature-induced errors and response delays.

Common Diaphragm Seal Designs

Different process requirements demand different diaphragm seal constructions.

1. Threaded Diaphragm-Seals

Used for standard pipe connections in general industrial services.

2. Flanged Diaphragm-Seals

Suitable for higher pressures, larger pipe sizes, and critical applications.

3. Flush Diaphragm-Seals

Designed so the diaphragm is flush with the process wall, ideal for viscous or slurry-type media.

4. In-Line Diaphragm-Seals

Installed directly in the pipeline where continuous flow conditions are required.

Each design ensures optimal pressure transmission while matching the mechanical and process constraints.

You can also read our article:

Materials and System Fill Fluids

Material selection plays a major role in diaphragm seal performance and longevity.

Diaphragm Materials

Common materials include:

Stainless steel alloys

Special corrosion-resistant alloys

Coated diaphragms for aggressive media

System Fill Fluids

The fill fluid must remain stable across the operating temperature range and be compatible with the application.

Standard industrial fluids for general service

Food-grade fluids for hygienic applications

Special fluids for oxygen or ultra-pure processes

The correct combination of diaphragm material and fill fluid ensures safety, accuracy, and compliance with industry standards.

Typical Applications of Diaphragm-Seals

Diaphragm seals are widely used across many industries due to their versatility.

Chemical and petrochemical processing

Oil and gas production and refining

Power plants and steam systems

Food and beverage manufacturing

Pharmaceutical and biotechnology plants

Water and wastewater treatment

Fertilizer and specialty chemical production

In all these applications, the diaphragm seal ensures reliable pressure measurement where direct instrument contact is not possible or advisable.

Accuracy Considerations with Diaphragm-Seals

A common concern is whether diaphragm seals affect measurement accuracy.

In practice:

Properly engineered diaphragm seals introduce only minimal error

Accuracy depends on diaphragm stiffness, fill fluid properties, and temperature stability

Correct selection ensures long-term measurement reliability

For critical applications, temperature effects and capillary influences must be considered during system design.

What we learn today?

A diaphragm-seal is not just an accessory but it is a important component for safe and reliable pressure measurement in challenging process conditions.

By isolating the pressure instrument from aggressive media, extreme temperatures, and clogging risks, diaphragm seals protect equipment, improve measurement stability, and reduce maintenance costs.

When selected and installed correctly, diaphragm seals allow pressure instruments to perform accurately and consistently, even in the most demanding industrial environments.

I hope you like above blog. There is no cost associated in sharing the article in your social media. Thanks for Reading !! Happy Learning