Table of Contents

ToggleTypes of Controllers in Instrumentation: Introduction

In every industrial plant, keeping a process stable is one of the biggest challenges.

Temperature must remain within limits, pressure should not fluctuate, flow must be controlled, and levels must not overflow or run dry.

This is where controllers play a very important role.

A controller is a device or software that compares the measured value of a process with the desired value (setpoint) and then decides how much correction is needed. Based on this correction, it sends signals to valves, motors, heaters, or other final control elements to bring the process back to normal.

In instrumentation, controllers are classified in many ways. Some are based on how they react to error, some are based on the technology used, and others are based on advanced control strategies. Understanding these types is very important for students, technicians, and engineers who work with PLC, DCS, or field instruments.

Let us now understand the most important types of controllers used in instrumentation, explained in simple words.

1. On–Off Controller

An on–off controller is the simplest type of controller. It has only two output states, fully ON or fully OFF. There is no gradual control in between.

When the process value goes below the setpoint, the output turns ON. When it goes above the setpoint, the output turns OFF. This causes the process to continuously move around the setpoint.

On–off control is used where precise control is not required and small fluctuations are acceptable. It is commonly used in thermostats, simple heaters, compressors, and level switches.

A common example is a home water tank motor that turns ON when level is low and turns OFF when the tank is full.

2. Proportional (P) Controller

In a proportional controller, the output changes in proportion to the error. If the error is large, the controller gives a strong output. If the error is small, the output is also small.

This type of controller responds faster than on–off control and provides smoother control. However, it cannot fully eliminate steady-state error, also called offset. This means the process may settle slightly away from the setpoint.

Proportional control is used where fast response is needed and a small offset is acceptable, such as in flow control or speed control systems.

3. Proportional + Integral (PI) Controller

A PI controller combines proportional action and integral action. The proportional part reacts to present error, while the integral part reacts to accumulated past error.

The main advantage of PI control is that it removes steady-state error. Even if the error is small, the integral part will keep increasing the output until the error becomes zero.

This is the most commonly used controller type in industrial plants. It is widely used in flow, level, and pressure control loops where smooth and accurate control is required.

Most control loops in PLC and DCS systems are configured as PI loops by default.

4. Proportional + Derivative (PD) Controller

A PD controller combines proportional action and derivative action. The derivative part reacts to how fast the error is changing.

This allows the controller to predict future error and take corrective action early. As a result, the response becomes faster and overshoot is reduced.

However, derivative action is very sensitive to noise in the signal. If the measurement is noisy, derivative control can cause unstable behavior.

PD controllers are mainly used in motion control, robotics, and position control systems where fast response is required.

5. Proportional + Integral + Derivative (PID) Controller

A PID controller combines all three actions: proportional, integral, and derivative. It gives fast response, removes steady-state error, and reduces overshoot.

Because of this balanced performance, PID is the most powerful and most widely used controller in industry. With proper tuning, PID can control almost any type of process.

PID controllers are used in temperature control, pressure control, flow control, furnace control, and speed control applications.

Almost every PLC and DCS system supports PID function blocks for loop control.

6. Pneumatic Controller

A pneumatic controller uses air pressure signals to perform control action. The standard signal range is 3 to 15 psi.

These controllers were widely used before electronic systems became common. They are still used in hazardous areas where electrical signals are not safe.

Pneumatic controllers are robust and reliable but slower compared to electronic and digital controllers. Maintenance is also higher due to air leaks and mechanical parts.

They are still found in old refineries, chemical plants, and remote locations.

7. Electronic (Analog) Controller

Electronic controllers use electrical signals such as 4–20 mA or 0–10 V to perform control action.

These controllers are faster and more accurate than pneumatic controllers. They are usually panel-mounted instruments used for single-loop control.

Analog controllers are easy to install and tune and are often used in small process plants or standalone machines.

They act as a bridge between traditional pneumatic systems and modern digital control systems.

8. Digital Controller (PLC/DCS Based)

In digital controllers, the control algorithm runs inside software. The controller logic is executed by PLC or DCS processors.

Digital controllers are highly flexible. Parameters can be changed easily, advanced strategies can be implemented, and diagnostics are available.

Almost all modern plants use digital controllers because they support networking, data logging, alarms, and remote monitoring.

PID, cascade, ratio, and many advanced control functions are implemented inside PLC and DCS systems.

9. Feedback Controller

A feedback controller uses the actual output measurement to correct the process. It continuously compares measured value with setpoint.

If any disturbance occurs, the controller reacts after the process is affected. This is the most common and basic form of control.

Almost all standard control loops in industry are feedback control loops.

Feedback control is simple and reliable but cannot prevent disturbances, it can only correct them after they happen.

10. Feedforward Controller

A feedforward controller reacts to disturbances before they affect the process.

It uses a disturbance measurement and calculates how much correction is required in advance. This helps in maintaining stable output even when disturbances occur.

Feedforward control is usually combined with feedback control to get better performance.

It is used in applications like fuel-air ratio control, heat exchanger control, and mixing processes.

Watch the difference beetween Feedback and Feedforward Control System

11. Cascade Controller

Cascade control uses two controllers working together. The main controller sets the setpoint for the secondary controller.

The secondary controller responds faster to disturbances, which improves overall system performance.

Cascade control is used when disturbances affect an inner loop before the main process variable.

A common example is temperature control using flow as secondary loop, where flow changes are corrected quickly before temperature gets affected.

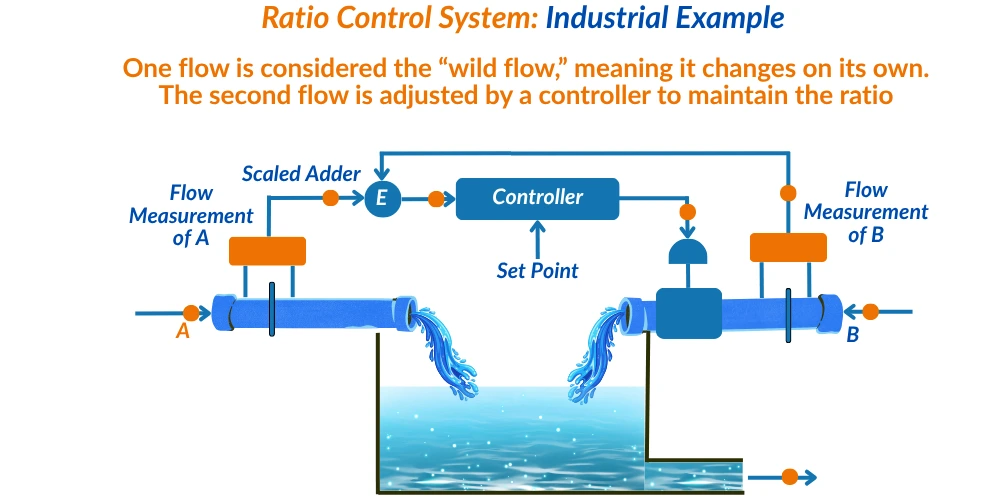

12. Ratio Controller

A ratio controller maintains a fixed ratio between two variables, usually two flows.

If one flow changes, the other automatically changes to maintain the ratio.

Ratio control is used in blending, combustion, and chemical mixing processes.

For example, maintaining proper air-fuel ratio in burners is done using ratio control.

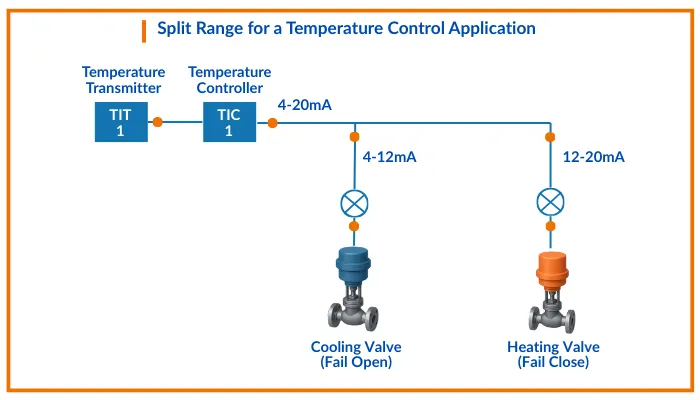

13. Split-Range Controller

In split-range control, one controller output is divided into two or more output ranges to operate multiple final control elements.

For example, one valve may operate from 0 to 50% output and another valve from 50 to 100% output.

This is used in heating-cooling systems, pressure control with two valves, and reactor temperature control.

Split-range helps in smooth transition between different operating modes.

14. Adaptive Controller

An adaptive controller automatically changes its tuning parameters based on process behavior.

When the process characteristics change, the controller retunes itself to maintain good performance.

This is useful in processes where dynamics vary frequently, such as batch processes or changing loads.

Adaptive control is part of advanced process control strategies and requires good modeling and computation.

What we learn today?

Controllers are the heart of any control system. No matter how good the sensors and valves are, without proper control logic the process will never remain stable.

Understanding different types of controllers helps engineers choose the right strategy for each application. Some processes need simple on–off control, while others require advanced cascade or adaptive control.

For students, learning these controller types builds strong fundamentals. For technicians, it helps in troubleshooting loops faster. For engineers, it improves system design and optimization.

If you are working with PLC, DCS, or SCADA systems, these controller concepts will appear again and again in your daily work.

Mastering them will make you a better instrumentation professional.

I hope you like above blog. There is no cost associated in sharing the article in your social media. Thanks for Reading !! Happy Learning