Table of Contents

ToggleWhat is Signal Conditioning?

When you measure something in industry temperature, pressure, flow, vibration – a sensor picks up the physical change and converts it into an electrical signal.

Often that raw signal is weak, noisy or not compatible with the next electronics stage (like a controller or data acquisition system).

That is where signal conditioning comes in: it “cleans-up” or changes the signal so that it can be processed accurately.

Signal conditioning ensures that the signal coming from the sensor is clean, strong, and accurate before it reaches the next device whether that’s a controller, recorder, or PLC.

In short, it acts as a bridge between the sensor and the control system.

Why is Signal Conditioning Important?

Without proper conditioning, the measurement signal may be distorted, too small to detect, or incompatible with the controller / system input. For example:

- A thermocouple might produce millivolt output which is too small and non linear for direct digitisation.

- A sensor in a noisy or high electrical interference environment may get corrupted before even reaching the system.

Thus, signal conditioning ensures accuracy, reliability and compatibility of measurement systems.

Main Types of Signal Conditioning

Below are the key types of signal conditioning functions to know:

1. Amplification

Many sensors produce very low-level signals (millivolts or microvolts). An amplifier boosts these small signals to higher levels suitable for processing.

Example:

A load cell outputs 10 mV at full load. The signal conditioner amplifies it to 5 V or converts it to a 4–20 mA current loop for long-distance transmission.

2. Filtering

Industrial environments often have electrical noise from motors, drives, or switching devices. Filters remove unwanted frequencies and allow only the useful signal to pass.

Example:

A low-pass filter can block high-frequency noise above 50 Hz while allowing the slow-changing temperature signal to pass smoothly.

3. Isolation

Isolation protects both the signal and the instrument. It separates the input from the output to prevent damage from voltage spikes, ground loops, or differences in potential.

Example:

In a large plant, a grounded temperature sensor may create a ground loop if connected directly to a PLC. An isolation amplifier eliminates that problem, ensuring clean readings.

4. Linearization

Some sensors don’t produce a linear output. A linearization circuit adjusts the signal so that changes in output are proportional to the measured variable.

Example:

Thermocouples have a nonlinear voltage–temperature relationship. The signal conditioner compensates for this curve, providing accurate temperature readings.

5. Signal Conversion

Different systems often use different signal standards. Signal converters change one type of signal into another (voltage to current, or frequency to voltage).

Example:

A vibration sensor outputs a frequency signal, but your control system needs 4–20 mA. The converter translates the frequency into a proportional current.

6. Excitation (Bridge Completion)

Sensors like strain gauges or RTDs need an external excitation voltage or current to function properly. Signal conditioners provide this power and sometimes complete the Wheatstone bridge.

Example:

A strain gauge bridge circuit requires a 5 V excitation. The conditioner supplies it and measures the resulting small resistance change accurately.

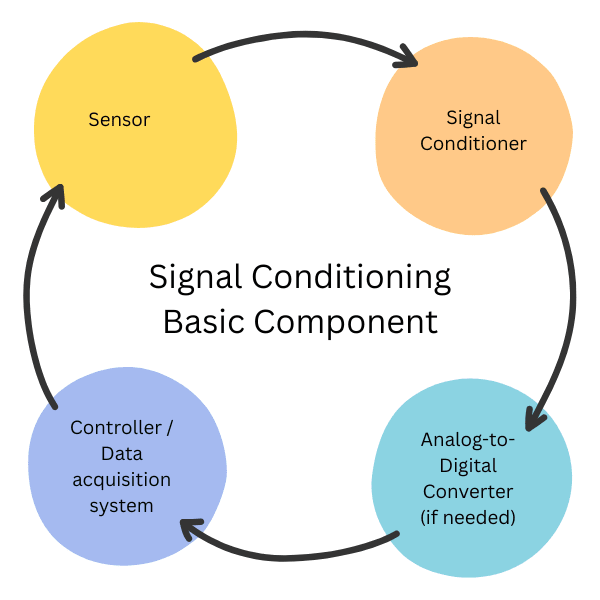

Where Does Signal Conditioning Sit in the Instrumentation Chain?

It generally sits between the sensor/transducer and the measurement/control system.

Sensor → Signal Conditioner → Analog-to-Digital Converter (if needed) → Controller / Data acquisition system.

Some Examples in Instrumentation

Here are how these types show up in practice:

1) A thermocouple in a furnace produces a tiny millivolt output and has cold junction effects. A conditioner amplifies, compensates, linearizes and outputs a standard 4-20 mA signal.

2) A load cell (force sensor) uses a strain gauge bridge. The conditioner supplies excitation, filters noise, amplifies signal and sends output to display or controller.

3) In a field instrument measuring vibration or pressure with small signals far from the controller, a module with isolation prevents interference and preserves measurement integrity.

What we learn today?

1) Always check the specifications of the sensor and measurement system: what output does the sensor provide, what input does the system expect?

2) Ensure the conditioning module matches the environment (noise levels, temperature, distance) to maintain accuracy.

3) Remember that some functions (filtering, isolation, excitation) are essential for reliable industrial performance skipping them may lead to measurement errors or system faults.

4) For students and newcomers: mastering signal conditioning means you can better design, specify or troubleshoot instrumentation systems.

I hope you like above blog. There is no cost associated in sharing the article in your social media. Thanks for reading!! Happy Learning!!