Table of Contents

ToggleReflux Ratio: Introduction

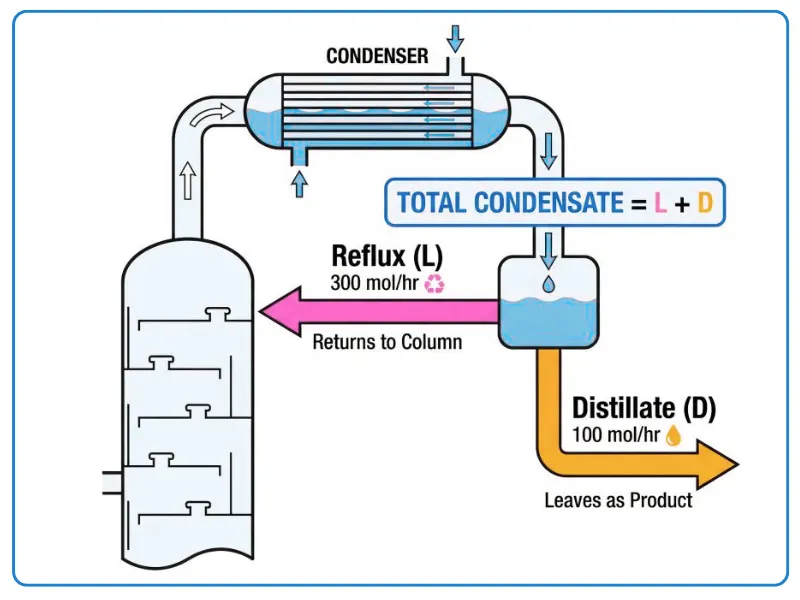

If you have ever seen a distillation column in a refinery, chemical plant, or solvent recovery unit, you may have noticed that not all the condensed liquid from the top is sent out as product. A good part of it is sent back into the column again.

This returned liquid is called reflux, and how much we return compared to how much we take as product is called the reflux ratio.

This single parameter plays a big role in deciding:

- How pure your product will be

- How much steam and cooling water you will consume

- How stable your column operation will be

That is why operators, process engineers, and instrumentation engineers all keep a close eye on reflux.

What Is Reflux Ratio

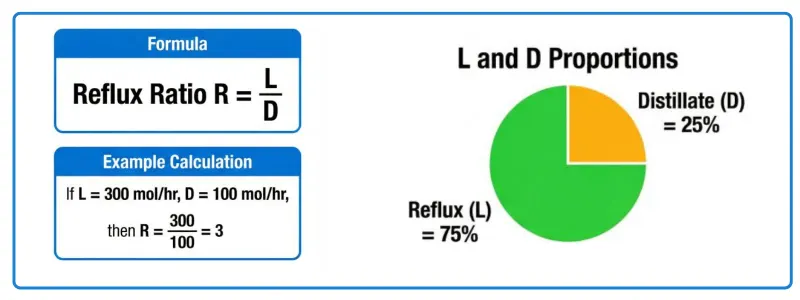

In very simple words, reflux ratio tells us how much liquid we send back into the column compared to how much we take out as distillate.

Basic definition of reflux ratio

Reflux ratio is the ratio of liquid returned to the column to the liquid withdrawn as overhead product.

Formula:

R = Ln / D

Where:

Ln = Amount of liquid returned to the column as reflux

D = Amount of distillate product withdrawn from the top

If you send back more liquid and take out less product, the reflux ratio becomes high.

If you send back less liquid and take out more product, the reflux ratio becomes low.

What Exactly Is Reflux in a Distillation Column

1. Where reflux comes from

Vapor from the top of the column enters the condenser and gets converted into liquid.

2. How liquid is split

This liquid enters the reflux drum where one part goes out as product and the remaining part returns to the column.

3. Why liquid is returned

Returned liquid helps improve vapor–liquid contact and improves separation quality.

How Reflux Improves Separation

1. Role of vapor–liquid contact

When vapor and liquid meet on trays or packing, mass transfer takes place between phases.

2. Direction of component movement

Light components prefer vapor phase and heavy components prefer liquid phase during contact.

3. Result of repeated contact

Repeated contact on multiple trays improves purity of top and bottom products.

Effect of High Reflux Ratio

1. Improvement in product purity

More liquid contact allows better removal of heavy components from vapor.

2. Increase in internal flow rates

High reflux increases liquid and vapor traffic inside the column.

3. Increase in energy consumption

More heating and cooling are required, increasing steam and cooling water usage.

Effect of Low Reflux Ratio

1. Reduction in energy usage

Less liquid circulation reduces reboiler and condenser duties.

2. Drop in separation efficiency

Reduced contact between vapor and liquid reduces separation quality.

3. Risk of off-spec product

Product composition may shift outside quality limits.

Important Operating Reflux Conditions

1. Total reflux condition

All condensed liquid is returned to the column and no product is withdrawn.

2. Minimum reflux condition

Lowest reflux where separation is theoretically possible, but requires infinite trays.

3. Optimum reflux condition

Actual operating reflux selected to balance purity, energy, and column size.

How Reflux Ratio is Controlled in Plants

1. Flow-based ratio control

Reflux and distillate flows are measured and controlled using a ratio controller.

2. Temperature-based control

Top tray temperature is used to adjust reflux to maintain composition.

3. Analyzer-based control

Online composition analyzers directly control reflux based on product quality.

Important Operating Points Engineers Talk About

In column design and operation, three reflux conditions are commonly discussed.

Total reflux (R = ∞)

At total reflux, all condensed liquid is returned to the column and no distillate is withdrawn. Since D becomes zero, reflux ratio becomes infinite. This condition gives the minimum number of theoretical stages, but it is not used for continuous production because you are not collecting product.

Minimum reflux

Minimum reflux ratio is the lowest reflux at which separation is just possible. It minimizes energy consumption, but the column would need an infinite number of stages to achieve separation. That is why minimum reflux is mainly a design concept and not practical for real plants.

Optimum reflux

In real operation, reflux is selected as a balance between purity, column size, and energy cost. Typically, optimum reflux is kept around 1.2 to 1.5 times the minimum reflux ratio. This gives stable separation without excessive energy consumption or an impractically tall column.

Common Problems Related to Reflux

1. Flooding due to excessive reflux

High liquid load can overload trays and reduce efficiency.

2. Poor purity due to low reflux

Insufficient liquid contact reduces separation.

3. Control instability

Poor tuning of reflux valve causes oscillations in column temperature and composition.

Why Reflux Ratio is Important for Energy Saving

1. Direct impact on reboiler duty

Higher reflux means higher steam or fuel consumption.

2. Direct impact on condenser duty

Cooling systems must remove more heat when reflux increases.

3. Major factor in operating cost

Even small reflux changes can significantly affect utility bills.

What we learn today?

Reflux ratio is a small formula, but it decides big outcomes in a distillation column.

More reflux usually means better purity but higher energy cost.

Less reflux usually means lower cost but lower purity.

That is why plants aim for an optimum reflux ratio, where separation is stable, product is on-spec, and energy use is reasonable.

I hope you like above blog. There is no cost associated in sharing the article in your social media. Thanks for Reading !! Happy Learning

2 Comments