Table of Contents

ToggleMetal Tube Rotameter –Introduction

Flow measurement in industrial plants is not always simple. In many applications, the fluid is hot, under high pressure, corrosive, or opaque. In such cases, a normal glass rotameter may not survive.

This is where a metal tube rotameter becomes the preferred solution.

In this article, let us understand its working principle, formula, construction, benefits, and real industrial applications.

What is a Metal Tube Rotameter?

A metal tube rotameter is a type of variable area flow meter used to measure the flow rate of liquids and gases in industrial processes.

Unlike glass rotameters, which are suitable for low pressure and visible fluids, metal tube rotameters are specially designed for:

High-pressure applications

High-temperature services

Turbid or opaque fluids

Chemically aggressive environments

Hazardous or explosion-prone areas

Because the measuring tube is made of metal, it provides superior mechanical strength and process safety. These instruments are widely used in oil & gas, chemical plants, power plants, and heavy industries.

In simple words, when the process becomes rugged, the metal tube rotameter becomes the right choice.

Working Principle of Metal Tube Rotameter

The metal tube rotameter works on the variable area principle.

At the heart of the instrument, there are two main parts:

A vertically mounted tapered metal tube

A freely moving float inside the tube

Let us understand step by step how it works.

The process fluid enters the rotameter from the bottom and flows upward through the tapered tube.

Initially, the float rests at the bottom due to gravity.

As the fluid flows upward, it exerts an upward force on the float.

The float rises until the upward force caused by flow equals the downward gravitational force of the float.

At this equilibrium position, the float stabilizes. The height of the float corresponds directly to the flow rate.

As the tube is tapered, the area between the float and tube wall increases as the float rises. Higher flow means higher float position.

This balance condition defines the flow measurement.

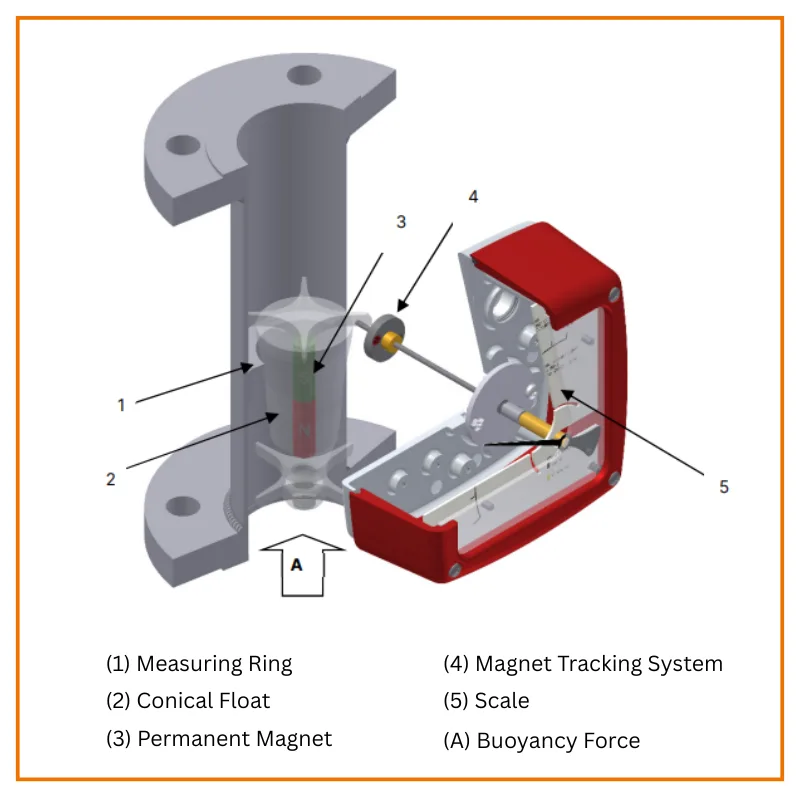

Please see below figure showing different parts of metal tube rotameter.

The measuring element consists of a sharp-edged measuring ring (1) and a conical float (2). A medium flows from the bottom to the top through the measuring ring, lifting the float until the buoyancy force (A) and the weight of the float establish equilibrium.

As the height of the float varies, an annular clearance proportional to the flow appears between the float and the measuring ring. The height of the float in the measuring ring is a measure of the flow. The permanent magnet (3) embedded in the float then transmits this measure to the scale (5) and by means of a magnet tracking system (4) to the optional electronic evaluation devices.

Basic Rotameter Formula

One simplified formula used in rotameters is:

Q = kA√(gH)

Where:

Q = volumetric flow rate

k = constant

A = annular area between float and tube

g = acceleration due to gravity

H = pressure drop across the float

This equation shows that flow rate depends on the annular area and pressure drop around the float.

How Flow is Indicated in Metal Tube Rotameter

In a glass rotameter, the float position is visible directly.

But in a metal tube rotameter, the tube is not transparent. So how do we read the flow?

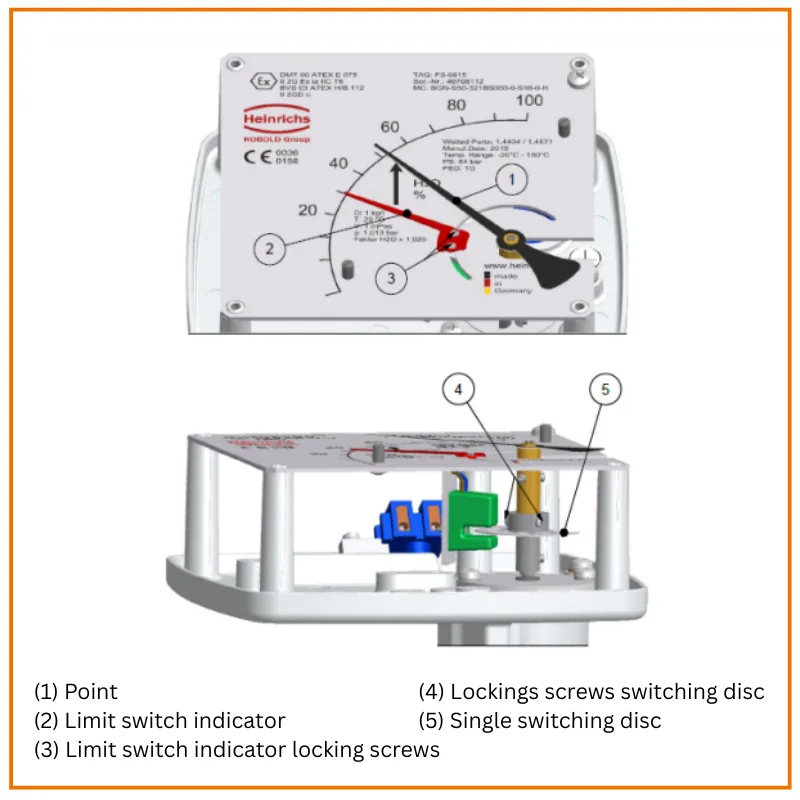

There are two common methods.

Magnetic Coupling System

The float inside the tube contains a magnet. Outside the tube, a follower magnet tracks the float position. This movement is mechanically linked to a pointer and scale.

As the float moves up or down, the external indicator shows the flow rate.

Electronic Display System

Modern metal tube rotameters use magnetic sensors and chip technology.

These advanced models can provide:

Instantaneous flow

Totalized (accumulated) flow

Percentage flow

LCD display

4–20 mA output

HART communication

Because the magnetic coupling has no direct mechanical penetration through the tube, leakage risk is eliminated and signal transmission remains stable.

Main Elements of a Metal Tube Rotameter

Let us understand its construction clearly.

1. Tapered Tube

The tube is metallic and gradually widens from bottom to top.

This taper ensures that different flow rates correspond to different float positions.

The tube material is usually stainless steel or special alloys for corrosive services.

2. Float

The float is precisely designed and often made of stainless steel or corrosion-resistant material.

Its weight and shape are carefully engineered to maintain stable equilibrium during operation.

3. Magnetic Coupling

The magnetic system transfers float position to the external indicator.

It ensures:

Leak-proof design

High reliability

Safe operation in hazardous areas

4. Indicator Mechanism

The indicator may be:

Analog pointer scale

LCD digital display

Remote transmitter with alarm settings

Advanced versions allow setting upper and lower alarm limits easily.

Benefits of Using Metal Tube Rotameter

Now let us see why industries prefer metal tube rotameters.

-

High Durability

The metallic body withstands mechanical stress and vibration.

-

High Pressure and Temperature Resistance

Suitable for steam, hydrocarbons, and hot process fluids.

-

Chemical Resistance

Works well with aggressive chemicals when proper materials are selected.

-

Suitable for Opaque Fluids

Even if the fluid is dark or dirty, measurement remains accurate.

-

Explosion-Proof Design

Many models are certified for hazardous areas.

-

Multiple Output Options

Supports 4–20 mA, pulse output, and HART protocol.

-

Alarm Functionality

Upper and lower alarm limits can be configured.

-

High Accuracy and Repeatability

One-time roll forming sensors provide stable and repeatable measurement.

Industrial Applications of Metal Tube Rotameter

Metal tube rotameters are widely used across industries.

1. Oil and Gas Industry

Used to measure crude oil, natural gas, condensate, and other hydrocarbons.

Because of their ability to handle high pressure, they are suitable for pipelines and wellhead services.

2. Chemical Industry

Used for corrosive chemicals, acids, and solvents.

Material selection plays a crucial role here.

3. Wastewater Treatment

Measures water flow and chemical dosing for pH control and disinfection.

4. Pharmaceutical Industry

Used in controlled processes for solvents and purified water systems.

5. Food and Beverage Industry

Sanitary versions are used to measure additives and ingredients in processing lines.

Installation Guidelines

Proper installation is critical for accuracy.

The metal tube rotameter must be installed vertically.

Flow direction should always be from bottom to top.

Horizontal installation is possible only in special designs and must be specified during ordering.

The instrument should be rigidly mounted to avoid vibration.

Isolation valves should be provided to protect the meter from sudden pressure surges.

Calibration Considerations

Calibration ensures measurement reliability.

Calibration should be done using a fluid with similar density and viscosity as the process fluid.

Many manufacturers provide factory calibration certificates.

Field calibration can be done using certified flow standards.

In magnetic systems, alignment between float magnet and external magnet must be correct. Misalignment leads to inaccurate readings.

What we learn today?

A metal tube rotameter is one of the most reliable and rugged flow meters available for industrial applications.

When you need:

Strength

High pressure resistance

High temperature tolerance

Chemical compatibility

Explosion-proof safety

This flow meter becomes a strong candidate.

In simple words, if a glass rotameter cannot survive in your process, a metal tube rotameter probably can.

Choosing the correct material, proper installation, and suitable calibration will ensure long-term stable and accurate performance.

And as always in instrumentation, the right selection depends on understanding the process conditions clearly before finalizing the instrument.

I hope you like above blog. There is no cost associated in sharing the article in your social media. Thanks for Reading !! Happy Learning