- July 17, 2025

Interface level measurement is very important topic in industrial level measurements. In industries like oil & gas, chemicals, and petrochemicals, it is very common to have tanks or vessels filled with two or more liquids.

For example, oil and water often exist together in a tank. These liquids don’t mix well and form separate layers because they have different densities (or specific gravity).

In simple terms, the lighter liquid floats on top of the heavier one.

Knowing where these two liquids meet called the interface level is very important.

Let us understand how engineers measure it using different types of level measuring techniques.

Table of Contents

ToggleImagine a bottle of salad dressing with oil and vinegar. The oil stays on top, and the vinegar stays at the bottom. The boundary between them is called the interface.

In industrial tanks, it is the same.

For example:

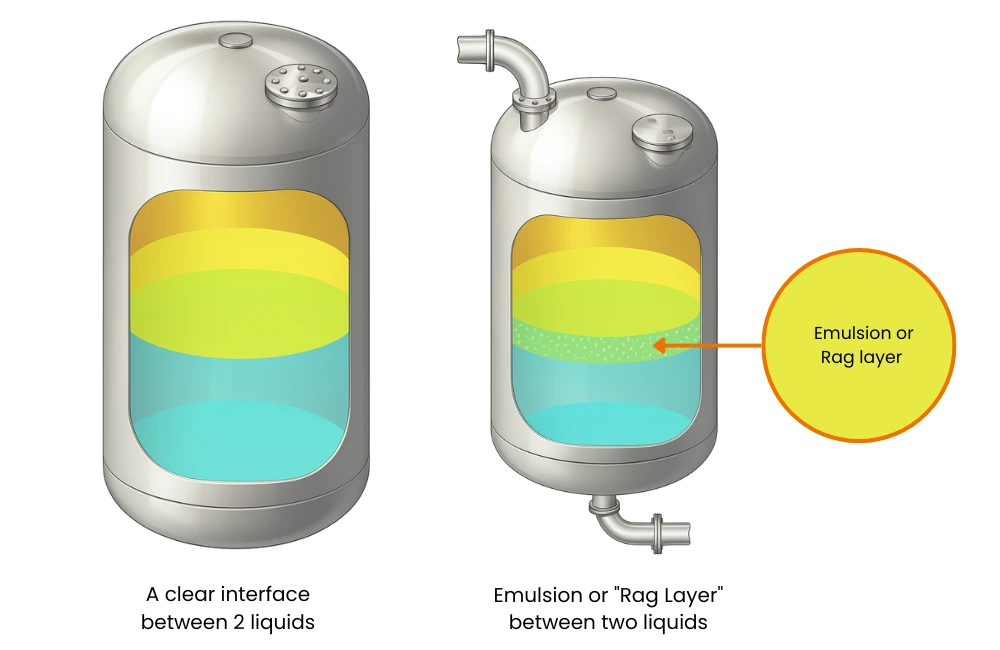

Sometimes the layers are clearly separate. Other times, there is a mixing layer in between, called a rag layer or emulsion layer — A cloudy zone where the two liquids partially mix.

Please see image below

Knowing the exact position of the interface helps operators:

Even a small mistake in separation can cause:

Most Interface level measurement techniques depends on the difference in density between two liquids. The bigger the difference, the easier it is to detect the interface. But if the liquids have similar densities, it becomes harder to measure the exact boundary.

Sometimes we also need to know:

Let us go through the most common measurement methods. Each has its own advantages and limitations.

A float rides on the surface of the top liquid. If there are two layers (like oil over water), it only measures the oil level.

A displacer, on the other hand, is submerged and designed to settle at the interface between two liquids. It balances based on the specific gravity (density) of the liquid it is sitting in.

– Very affordable and easy to understand

– Good for basic interface detection

– Can be used in non-hazardous, low-pressure tanks

– Only works if you know the densities of the liquids and they don’t change.

– If the liquids stick to the float or displacer, readings become inaccurate.

– Turbulence in the tank causes float instability.

– Rag layers can confuse the reading.

– Simple storage tanks

– Oil-water separation vessels

– Industrial water tanks

A probe inside the tank acts like part of a capacitor.

One liquid (e.g., water) is conductive, and the other (e.g., oil) is non-conductive.

The probe detects the change in capacitance at the interface.

– Works even if a rag layer is present.

– Good for narrow interface zones.

– Can be used in small or narrow tanks.

– If conductivity of the fluid changes, accuracy drops.

– Can only measure one parameter at a time: either interface or thickness of conductive fluid — not both.

– Not suitable for changing product types.

– Chemical mixing tanks

– Oil/water separator units

– Food & beverage and pharma industries (when materials are stable)

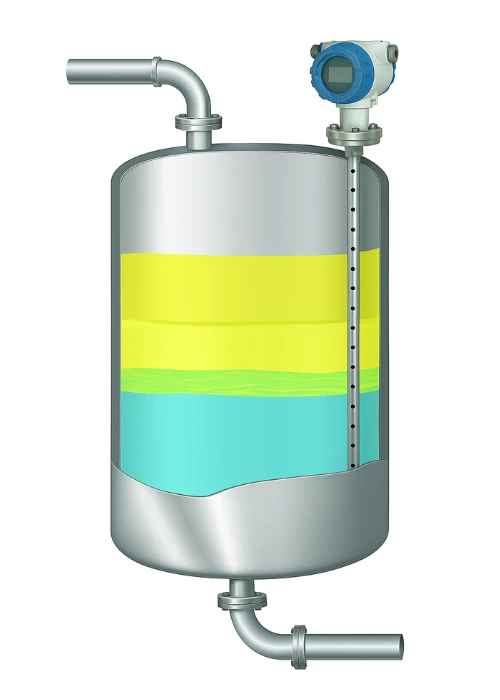

A radar signal travels down a rod or cable inside the tank.

The signal bounces back at two points:

Top surface of the upper liquid (like oil)

Interface between oil and water (due to difference in dielectric constant)

– A radar signal travels down a rod or cable inside the tank.

– The signal bounces back at two points:

– Top surface of the upper liquid (like oil)

– Interface between oil and water (due to difference in dielectric constant)

– Measures both top level and interface.

– No effect from density, pressure, or vapor.

– Works in pressurized or high-temp environments.

– Can be installed in long vertical tanks (up to 30 ft).

– Needs minimum 10 dielectric difference (dk) between the two liquids.

– Does not work well with thick rag layers.

– Must be configured properly for accurate multi-layer detection.

Combines guided wave radar + capacitance in a single probe.

If radar signal is blocked by an emulsion, the device automatically switches to capacitance mode.

– Handles rag layers + gives top and interface levels.

– Switches automatically based on conditions.

– Tracks multiple tank echoes and ignores false readings from tank structures.

– Higher cost

– Requires skilled configuration

– May not be needed in simple two-liquid systems

– Advanced oil-water-gas separator tanks

– Tanks with variable or unpredictable fluids

– Refining and high-precision chemical processing

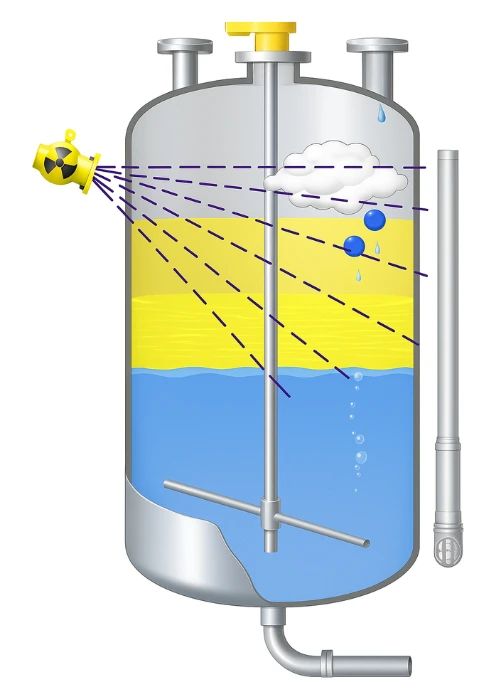

A gamma source emits radiation across the tank.

A detector on the opposite side measures how much radiation gets through.

Denser materials (like water) block more radiation, lighter ones (like oil) block less.

Multiple detectors allow mapping of multiple interfaces or layers.

– Works without touching the liquid (non-invasive).

– Can penetrate metal tanks, foam, vapor, and sludge.

– No moving parts so no maintenance

– Great for very large or pressurized tanks

– Expensive

– Requires nuclear safety permits and regulations

– Needs trained personnel for installation and compliance

– Heavy oil & gas applications

– Refineries and multiphase separators

– Harsh and high-pressure chemical reactors

The sensor sends an ultrasonic sound wave into the liquid.

When it hits a layer of solid material (like sludge or salt), the signal reflects back.

The time taken tells how deep the solid layer is.

– Useful in solid/liquid interfaces

– Works well in wastewater, mining, and chemical sedimentation tanks

– Non-invasive if mounted externally

– Does not work with liquid-liquid interfaces (e.g., oil/water)

– Not reliable in bubbly or foamy liquids

– May need calibration if solids settle unevenly

– Sludge monitoring in wastewater treatment

– Brine/salt separation tanks

– Mining thickener applications

Sight glass: A transparent tube shows the liquid levels directly. This is very rate method used in Interface level measurements.

DP (Differential Pressure): Measures pressure difference between top and bottom to calculate level.

Bubble tubes: Blows air from bottom of tank, back pressure gives level information.

– Very simple and low cost

– Good for visual checks or non-critical applications

– Manual reading (sight glass)

– Can not show multiple layers or interfaces clearly

– DP depends on stable fluid density

– Bubble tubes may get clogged or affected by coating fluids

– Small tanks

– Backup readings

– Educational labs or training facilities

Not every sensor fits every situation. Here is what you should think about before selecting:

1) What two liquids are you measuring?

2) Are they conductive or non-conductive?

3) Do they form a rag/emulsion layer?

4) Is the interface clearly defined or changing?

5) Do you need just the interface, or interface + overall level?

6) Is the tank pressurized, hot, or dirty?

7) What is your budget?

There is no single sensor that solves all interface level challenges. Often, two sensors are used together.

For example:

Whenever in doubt, it is always best to:

Here we learned what is Interface level measurement and different technologies used for the same.

I hope you like above blog. There is no cost associated in sharing the article in your social media. Thanks for reading!! Happy Learning!!

2 Comments