Table of Contents

ToggleIndustrial dryers and evaporators are widely used process equipment in many industries where moisture or solvents must be removed from liquids, slurries, or solids.

These systems are essential wherever concentration, drying, or volume reduction is required before storage, packaging, or further processing.

Although dryers and evaporators may look similar in purpose, their operation, design focus, and end results are slightly different.

Understanding how they work and where they are applied helps engineers and technicians select the right system for their process.

This article explains industrial dryers and evaporators in simple words, focusing on their working principles, applications, design considerations, and advantages

What Are Industrial Dryers and Evaporators?

Industrial dryers and evaporators are thermal process equipment used to remove liquid from a product.

Industrial Evaporators

Evaporators remove part of the liquid from a solution by converting it into vapor. The main goal is to increase concentration, not to completely dry the product.Industrial Dryers

Dryers remove almost all moisture from a product, resulting in a dry solid or powder.

In simple terms:

Evaporators concentrate

Dryers dry completely

Both systems rely on heat transfer and mass transfer to perform their function.

Basic Difference Between Drying and Evaporation

Understanding the difference helps avoid confusion during process design.

Evaporation

Removes liquid from a solution

Product remains in liquid or slurry form

Used when concentration is required

Example: Concentrating sugar syrup or chemical solutions

Drying

Removes moisture almost completely

Product becomes solid or powder

Used for storage stability and packaging

Example: Drying milk powder or pharmaceutical granules

Many processes use both evaporators and dryers in sequence.

Working principle of industrial dryers and evaporators

The basic working principle of dryers and evaporators is based on heat transfer and phase change.

Heat is supplied to the product using steam, electricity, hot water, or hot gases.

The liquid component absorbs heat and changes from liquid to vapor.

The generated vapor separates from the product.

Vapor is removed using separators, condensers, or exhaust systems.

The remaining product becomes concentrated or dry, depending on the process.

Proper control of heat and vapor removal is essential to protect product quality.

Main components used in evaporators

Although evaporator designs vary, most systems include the following components.

A heating section that transfers heat to the product.

An evaporation chamber where liquid boiling occurs.

A vapor separator that prevents liquid carryover.

A condenser that converts vapor back into liquid, when recovery is required.

A discharge section that removes the concentrated product.

Each component must be properly designed to ensure stable operation.

Main components used in industrial dryers

Industrial dryers also vary in construction, but common components include the following.

A drying chamber where moisture removal takes place.

A heat source that provides controlled heating.

An air or gas circulation system that carries moisture away.

A product discharge system for safe removal of dried material.

A dust collection system to reduce losses and improve safety.

The design depends on product type and required drying performance.

How the process works step by step

The complete drying or evaporation process follows a clear sequence.

The product enters the system through an inlet.

Heat is applied in a controlled manner.

Liquid inside the product turns into vapor.

Vapor separates and exits the system.

The product becomes concentrated or fully dried.

The final product is discharged for further use.

Each step must be carefully monitored to avoid overheating or product damage.

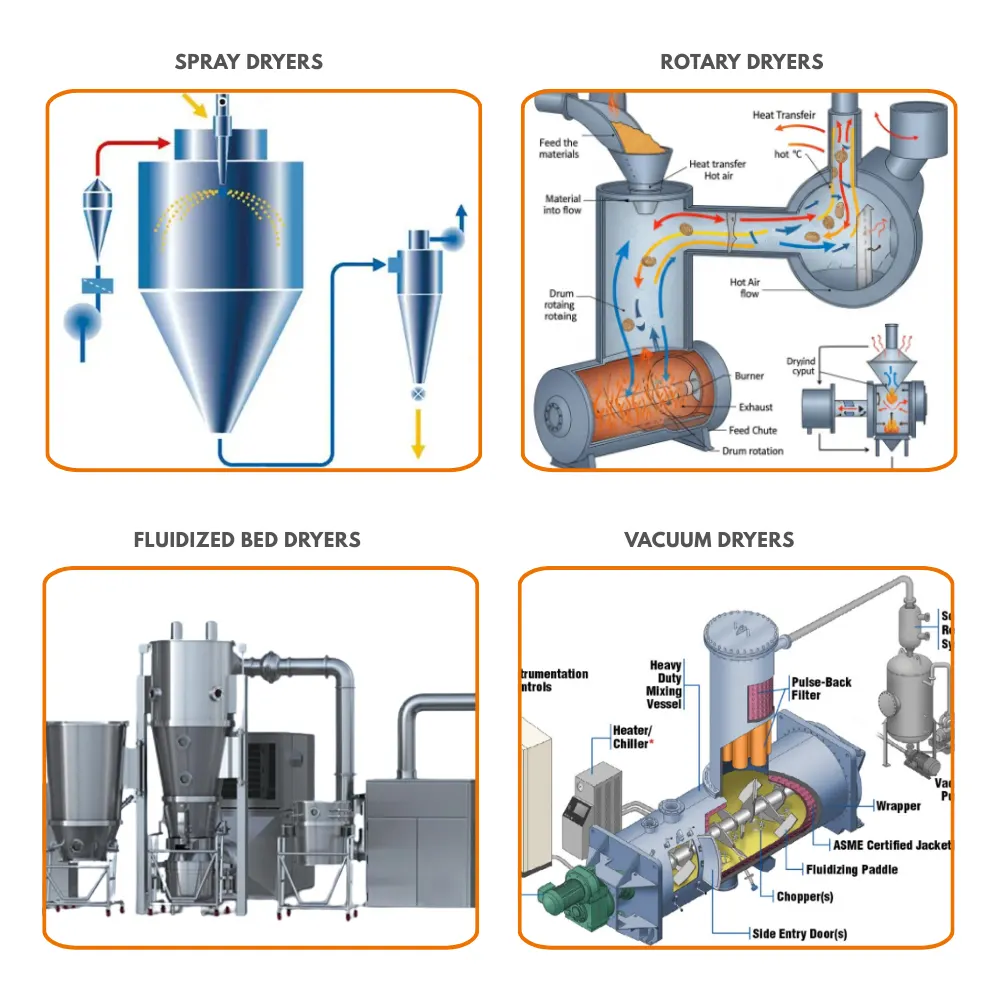

Types of industrial dryers

Industrial dryers are available in different designs to suit product characteristics, capacity requirements, and operating conditions. Each type works on a specific drying principle.

Tray dryers

Tray dryers are commonly used in pharmaceutical, chemical, and food processing industries where batch drying is required.

The product is spread evenly on trays, which are placed inside a closed chamber.

Heat transfer takes place mainly through conduction from the trays and convection from hot air circulating inside the chamber.

Tray dryers are simple in design and suitable for small to medium production volumes.

Spray dryers

Spray dryers are widely used in food, chemical, and pharmaceutical industries for producing powders from liquids.

The liquid product is atomized into fine droplets using a nozzle or rotary atomizer.

Hot air rapidly dries the droplets as they fall through the drying chamber.

This method provides fast drying and uniform particle size.

Rotary dryers

Rotary dryers are used in industries such as minerals, fertilizers, food processing, and chemicals.

The system consists of a rotating cylindrical drum through which the material moves.

Hot air passes through the drum and removes moisture from the material.

Rotary dryers are suitable for high-capacity and continuous drying applications.

Fluidized bed dryers

Fluidized bed dryers are commonly used in pharmaceutical, chemical, and food processing industries.

Hot air is passed upward through a bed of particles, causing them to behave like a fluid.

This fluidization ensures uniform heat transfer and consistent drying.

These dryers provide good temperature control and short drying times.

Vacuum dryers

Vacuum dryers are used for heat-sensitive materials, pharmaceuticals, and fine chemicals.

Drying takes place under reduced pressure, which lowers the boiling point of the liquid.

This allows moisture removal at lower temperatures.

Vacuum dryers help protect product quality and prevent thermal degradation.

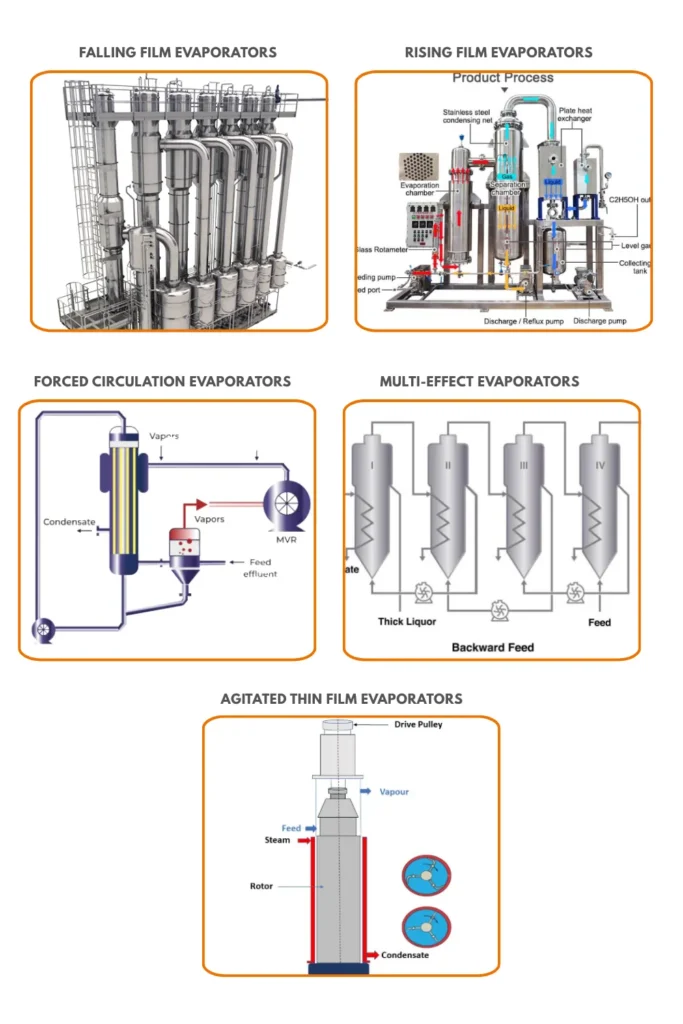

Types of industrial evaporators

Industrial evaporators are designed to concentrate liquids by removing a portion of the solvent. The selection depends on viscosity, heat sensitivity, and energy efficiency requirements.

Falling film evaporators

Falling film evaporators are widely used in food processing and chemical manufacturing.

The liquid forms a thin film that flows downward along heated vertical tubes.

Heat transfer occurs through the tube walls, causing rapid evaporation.

These evaporators are suitable for heat-sensitive products due to short residence time.

Rising film evaporators

Rising film evaporators are commonly used for dairy products, sugar solutions, and chemical processing.

The liquid enters at the bottom of the tubes and rises upward due to vapor formation.

The rising motion creates a thin film that evaporates quickly.

These systems are suitable for low-viscosity liquids.

Forced circulation evaporators

Forced circulation evaporators are used for concentrating viscous solutions and in crystallization processes.

A pump forces the liquid through the heating surface at high velocity.

This circulation improves heat transfer and reduces fouling.

These evaporators handle difficult products more effectively.

Multi-effect evaporators

Multi-effect evaporators are used in desalination, chemical manufacturing, and wastewater treatment.

Steam from one evaporator effect is used as the heating medium for the next effect.

This reuse of energy improves overall efficiency.

Multi-effect systems significantly reduce steam consumption.

Agitated thin film evaporators

Agitated thin film evaporators are used for heat-sensitive and highly viscous materials.

Rotating blades spread the liquid into a thin film on the heated surface.

The thin film improves heat transfer and evaporation rate.

These evaporators provide precise control and short residence time.

Applications of industrial dryers and evaporators

Industrial dryers and evaporators are used across many industries due to their versatility.

Chemical industry

Used for chemical concentration and solvent recovery.

Helps reduce waste volume and disposal costs.

Supports continuous and batch processing operations.

Food and beverage industry

Used for milk, juice, and syrup concentration.

Used for drying food powders and ingredients.

Gentle heating is used to preserve taste and quality.

Pharmaceutical industry

Used for drying heat-sensitive products.

Helps improve product stability and shelf life.

Cleanability and hygiene are key requirements.

Water and wastewater treatment

Used for sludge drying and volume reduction.

Helps achieve zero liquid discharge goals.

Reduces transportation and disposal costs.

Pulp and paper industry

Used for concentrating black liquor.

Supports chemical recovery processes.

Large-capacity evaporators are commonly used.

Design considerations for dryers and evaporators

Selecting the right system requires careful evaluation of several factors.

Product heat sensitivity

Some products degrade at high temperatures.

Low-temperature or vacuum operation is preferred in such cases.

Required evaporation or drying rate

Higher capacity systems require larger heat transfer areas.

Energy input must match the process demand.

Energy efficiency

Energy consumption affects operating cost.

Heat recovery and multi-effect systems improve efficiency.

Fouling and scaling tendency

Products with solids may deposit on heating surfaces.

Designs should allow easy cleaning and maintenance.

Material of construction

Material selection depends on corrosion and hygiene needs.

Stainless steel is commonly used in most industries.

Operating pressure and temperature

Higher pressure allows higher boiling temperatures.

Vacuum operation lowers boiling point and protects product quality.

Ease of cleaning and maintenance

Systems should allow easy access.

Clean-in-place features reduce downtime.

Advantages of industrial dryers and evaporators

Industrial dryers and evaporators offer multiple process benefits.

Improved product quality

Controlled heating preserves product properties.

Uniform drying improves consistency.

Cost-effective operation

Reduced product volume lowers storage cost.

Transportation cost is also reduced.

Better moisture control

Accurate control improves shelf life.

Moisture variation is minimized.

Enhanced process efficiency

Automation reduces manual intervention.

Stable operation improves productivity.

Improved sustainability

Waste generation is reduced.

Energy optimization supports environmental compliance.

Role of instrumentation in dryers and evaporators

Instrumentation is essential for safe and reliable operation.

Temperature measurement controls heating.

Pressure measurement ensures safe operation.

Level measurement prevents overflow or dry running.

Flow measurement controls feed and vapor removal.

Moisture measurement ensures product quality.

Accurate instrumentation improves control and consistency.

What we learn today?

Industrial dryers and evaporators are very important process equipment used to remove moisture or solvents from products.

Evaporators increase concentration, while dryers remove moisture almost completely. Their operation depends on controlled heat transfer, phase change, and vapor separation.

Proper selection and design improve product quality, reduce operating costs, and enhance process efficiency. When supported by correct instrumentation and maintenance, dryers and evaporators deliver reliable performance across many industries.

I hope you like above blog. There is no cost associated in sharing the article in your social media. Thanks for Reading !! Happy Learning