Table of Contents

ToggleNitrogen Purging: Introduction

In many industrial processes, controlling oxygen and moisture is not optional but it is critical.

Even small amounts of air or water vapor inside a system can lead to corrosion, oxidation, product degradation, fire risk, or poor process quality.

This is where nitrogen purging is used.

Nitrogen purging is widely used across industries such as oil & gas, chemicals, power plants, electronics, food processing, pharmaceuticals and metal fabrication.

Its main purpose is simple: replace air with an inert, dry, non-reactive gas => nitrogen (N₂).

1. What Is Nitrogen Purging?

Nitrogen purging is a process in which nitrogen gas is introduced into a system to displace unwanted gases, mainly oxygen, moisture, and contaminants.

Instead of leaving air inside vessels, pipelines, tanks, or equipment, nitrogen is used to create a controlled inert atmosphere.

This is important because:

Oxygen supports oxidation and combustion

Moisture causes corrosion, rust, and microbial growth

Air contains contaminants that can damage sensitive processes

Nitrogen is ideal because it is:

Chemically inert

Dry

Non-flammable

Readily available

Cost-effective for industrial use

2. Why Nitrogen Is Used for Purging

Nitrogen makes up about 78% of atmospheric air, but when supplied industrially, it is clean, dry, and controlled.

The main objectives of nitrogen purging include:

Inerting

Nitrogen does not react with most substances. Replacing air with nitrogen removes oxygen and reduces the risk of fire, explosion, or unwanted chemical reactions.Oxygen Removal

Many materials degrade quickly in the presence of oxygen. Nitrogen purging protects products, equipment, and pipelines by keeping oxygen levels low.Moisture Control

Nitrogen is extremely dry. Purging helps remove water vapor, preventing corrosion, condensation, mold growth, and freeze damage.Contaminant Removal

Dust, vapors, fumes, and residual gases are flushed out, creating a clean internal environment.

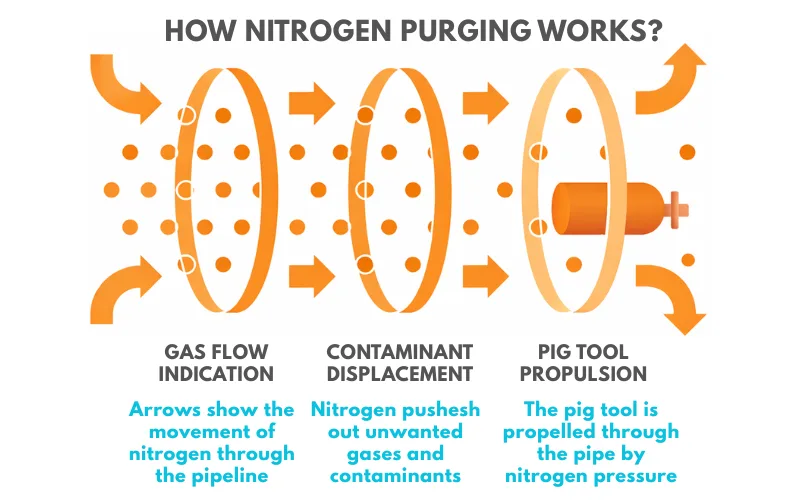

3. How Nitrogen Purging Works (Basic Principle)

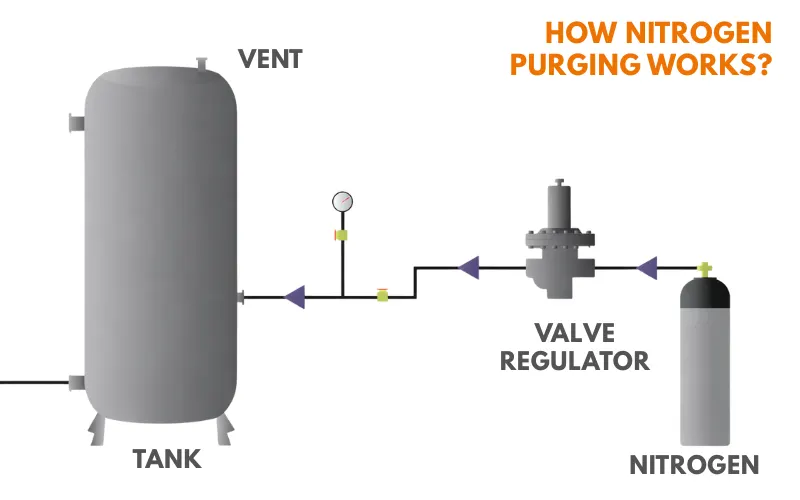

Nitrogen purging works by replacing oxygen and other hazardous gases with inert nitrogen. As nitrogen enters the system, it forces the existing gases out, creating a safe and non-reactive environment.

The working principle of nitrogen purging is straightforward.

Nitrogen gas is introduced into the system through an inlet

The nitrogen pushes out existing air or process gases

Displaced gases exit through a vent or outlet

Over time, oxygen concentration drops to a safe or required level

Depending on the method used, nitrogen may:

Completely displace air

Dilute air gradually

Pressurize and vent repeatedly

The final result is a nitrogen-rich, low-oxygen environment.

Nitrogen is commonly used for oxygen displacement because it is inert, easy to source, and does not react with process materials or equipment.

4. How Nitrogen Purging Differs from Other Purging Methods

Not all purging methods are the same. Each has advantages and limitations.

Steam Purging

Steam is effective for cleaning but introduces moisture. It is unsuitable for moisture-sensitive systems and often requires drying afterward.Vacuum Purging

Vacuum systems remove gases by suction. While effective, they require expensive equipment and may not work well for large volumes.Carbon Dioxide (CO₂) Purging

CO₂ displaces oxygen but can be corrosive and may introduce moisture. It is less inert than nitrogen in many applications.

Nitrogen remains the preferred choice because it is dry, inert, safe, and process-friendly.

5. Why Nitrogen Purging Is Necessary in Industry

Nitrogen purging is not just a best practice—it is often a safety and quality requirement.

Without purging:

Oxygen causes oxidation and corrosion

Moisture leads to rust and microbial growth

Flammable environments become dangerous

Product quality degrades

Equipment life is reduced

Nitrogen purging ensures:

Process stability

Extended equipment life

Improved product consistency

Safer working conditions

6. Common Industrial Applications of Nitrogen Purging

Nitrogen purging is used across many industries, including:

Oil & Gas

Used for pipeline commissioning, tank blanketing, and explosion prevention.Chemical & Petrochemical Plants

Removes oxygen to prevent unwanted reactions and degradation.Power & Electrical Systems

Protects transformers and switchgear from moisture and oxidation.Food & Beverage Industry

Used in modified atmosphere packaging to extend shelf life.Breweries

Purges oxygen from tanks and headspaces to preserve flavor.Electronics Manufacturing

Prevents oxidation during soldering and semiconductor processes.Metal Fabrication & Welding

Improves weld quality by eliminating oxygen contamination.

7. Four Types of Nitrogen Purging Systems

Different systems require different purging techniques.

7.1 Displacement Purging

Nitrogen directly pushes air out of the system.

Best for pipelines and simple vessels.

7.2 Dilution Purging

Nitrogen mixes with existing gases and gradually reduces oxygen concentration.

Suitable for complex equipment like reactors and columns.

7.3 Pressure Liquid Transfer

Nitrogen pressurizes a vessel to move liquids without pumps.

Reduces oxidation during transfer.

7.4 Pressure-Hold Vacuum Method

Repeated pressurization and venting cycles reduce oxygen levels.

Used when only one vent point is available.

8. Factors That Affect Nitrogen Purging Efficiency

Several parameters influence how effective purging will be:

Pressure & Flow Rate

Too low leads to incomplete purging; too high creates turbulence.Inlet and Outlet Positioning

Incorrect placement causes trapped air pockets.System Geometry

Dead legs and complex piping require special attention.Temperature

Cold conditions may affect nitrogen behavior and density.Nitrogen Purity

Higher purity ensures better oxygen displacement.

9. Nitrogen Purging in Pipelines

Pipeline purging is essential during:

New pipeline commissioning

Maintenance shutdowns

Product changeovers

Nitrogen removes:

Oxygen

Moisture

Dust and debris

This prevents corrosion, flow issues, and safety hazards before the pipeline is put into service.

10. Safety Considerations During Nitrogen Purging

Nitrogen is safe but oxygen-deficient environments are not.

Key safety measures include:

Proper personnel training

Use of oxygen monitors

Clear ventilation paths

Emergency shutdown procedures

Mandatory PPE

Strict work permits and supervision

Nitrogen purging should always be treated as a controlled operation, not a routine task.

What we learn today?

Nitrogen purging is one of the most reliable and widely used techniques for controlling oxygen, moisture, and contamination in industrial systems.

Whether it is a pipeline, vessel, transformer, or packaging line, nitrogen purging ensures:

Safety

Product integrity

Process efficiency

Equipment protection

When designed and executed correctly, nitrogen purging becomes a silent guardian of industrial reliability.

I hope you like above blog. There is no cost associated in sharing the article in your social media. Thanks for Reading !! Happy Learning