Table of Contents

TogglePressure protection is one of the most critical safety requirements in oil and gas facilities.

A single uncontrolled overpressure event can result in pipeline rupture, equipment damage, fire, explosion, or serious environmental impact. Traditionally, pressure relief valves have been used as the primary line of defense.

Modern operating conditions and strict environmental regulations have made conventional relief systems less practical in many applications.

The HIPPS System in Oil and Gas is introduced to address these challenges by preventing overpressure rather than relieving it.

Understanding the HIPPS System in Oil and Gas

HIPPS stands for High Integrity Pressure Protection System. It is sometimes also referred to as High Integrity Protection System, but technically it is focused on pressure protection.

HIPPS is a safety-critical system designed to protect downstream equipment from excessive pressure by isolating the pressure source at the right time.

Unlike relief valves that release pressure to flare or atmosphere, HIPPS stops the flow before pressure exceeds the design limit. This makes the HIPPS system in oil and gas especially valuable in high-pressure and environmentally sensitive installations.

Prevent pressure rather than relieve pressure.

Why HIPPS is Required in Oil and Gas Plants

In earlier plant designs, venting hydrocarbons through relief valves was considered acceptable. Today, this approach is often restricted due to safety and environmental concerns. In many cases, the relief system itself may introduce a higher risk than the overpressure event.

HIPPS becomes necessary under conditions such as:

Venting hydrocarbons to atmosphere or flare is unsafe or restricted

Relief valve size and flare system become excessively large and expensive

Maintenance and inspection of large relief systems are impractical

The relief system may create additional hazards such as radiation or toxic exposure

Under these conditions, a HIPPS system in oil and gas provides a safer alternative by preventing pressure buildup at the source.

When Do We Need a HIPPS System?

HIPPS is not intended to replace relief valves in all situations. It is applied only when traditional pressure protection methods are not adequate or acceptable.

A HIPPS system in oil and gas is typically considered in:

Offshore platforms with limited space and flare capacity

Subsea pipelines where pressure relief is impractical

High-pressure gas wells feeding low-pressure facilities

Remote installations with strict environmental regulations

In most projects, the need for HIPPS is identified during pressure relief and hazard analysis studies.

HIPPS and Conventional Relief Devices

It is important to understand that HIPPS is not a complete substitute for conventional relief devices. Mechanical relief valves are self-actuated and respond to overpressure regardless of its cause. They have been proven reliable for over a hundred years.

HIPPS is introduced as an additional protection layer when:

Mechanical relief alone is insufficient

Venting creates unacceptable risk

Specific overpressure scenarios need to be mitigated

In many plants, HIPPS and relief valves coexist, each addressing different scenarios.

HIPPS Workflow Explained Step-by-Step

Let us now understand how a HIPPS system is developed and approved in real projects.

Step 1: Determine if HIPPS is the Right Solution

Not every overpressure problem needs HIPPS.

At this stage:

Defined criteria for HIPPS application must be met

Conventional relief options are evaluated first

Economic, safety, and environmental aspects are reviewed

Only when traditional methods are inadequate does HIPPS move forward.

Step 2: Perform LOPA for Overpressure Scenario

This is the most critical step.

During LOPA:

Overpressure scenario is clearly defined

All Independent Protection Layers (IPLs) are identified

Risk reduction required is calculated

Required SIL for the HIPPS SIS is determined

This analysis justifies the need for a HIPPS System in Oil and Gas.

Step 3: Design and Installation as per SIS Lifecycle

Once SIL is defined:

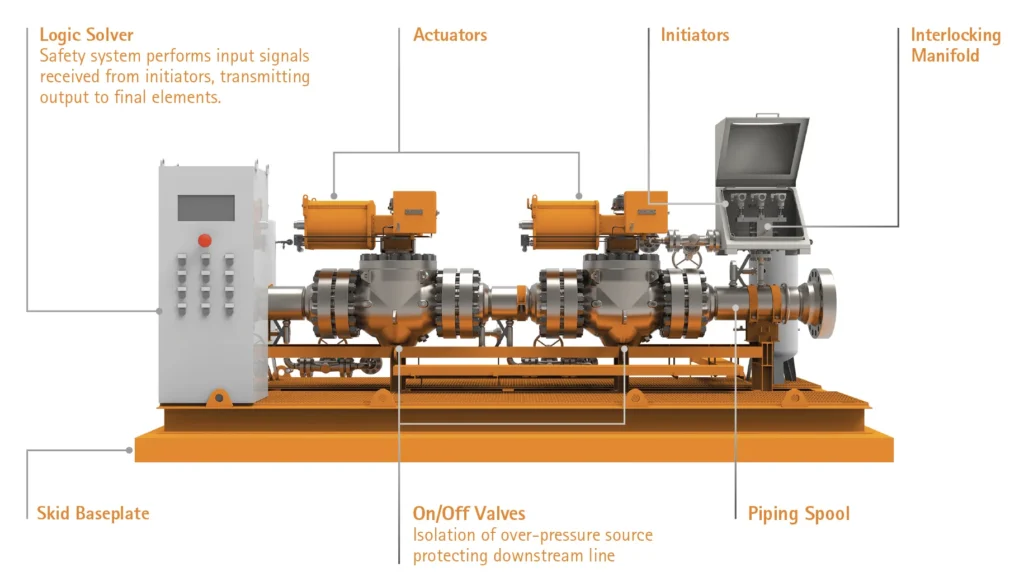

HIPPS is designed as a Safety Instrumented Function (SIF)

All SIS design rules apply

Hardware redundancy is evaluated

Proof testing requirements are defined

HIPPS is not treated as a standalone system—it becomes part of the plant SIS.

Step 4: Integrity Management and Auditing

All HIPPS systems:

Are tracked within SIS/LOPA records

Follow the same integrity management process

Are periodically audited

Require functional testing

This ensures long-term reliability.

Step 5: Final Review and Approval

Before commissioning:

End user performs final review

All documents are approved

Mechanical and SIS integrity files are updated

Formal acceptance is recorded

Safety Integrity Level (SIL) Requirement for HIPPS

Every HIPPS must meet a defined Safety Integrity Level. The minimum SIL requirement for HIPPS is usually SIL-1, but the actual SIL depends on the results of a Layer of Protection Analysis (LOPA).

LOPA helps determine:

The severity of the overpressure consequence

The frequency of initiating events

The risk reduction required from HIPPS

Based on this analysis, the appropriate SIL level is assigned, and the HIPPS is designed accordingly.

HIPPS Registration and Approval

HIPPS systems are formally registered in the pressure relief registry. This registration documents why HIPPS was selected and which overpressure scenario it mitigates.

Registration records include:

LOPA scenario number and description

SIF numbers and their functions

Reason for using HIPPS

Authorized approvals from engineering and operations

This step ensures transparency and accountability in safety-critical decisions.

Advantages of HIPPS System in Oil and Gas

When properly designed, a HIPPS system in oil and gas offers several advantages:

Reduces dependence on large relief valves and flare systems

Improves environmental protection

Enables compact and cost-effective plant design

Protects downstream equipment from overpressure

These benefits are realized only when HIPPS is correctly engineered and maintained.

Limitations and Engineering Responsibility

Despite its advantages, HIPPS has limitations. It depends on instruments, logic solvers, and final elements, which introduces the risk of common cause failures. Regular testing, maintenance, and disciplined integrity management are essential.

Mechanical relief devices remain the preferred first line of defense, and HIPPS should never be applied without proper justification.

What we learn today?

The HIPPS System in Oil and Gas represents a preventive approach to pressure protection. By stopping pressure at its source, HIPPS helps protect people, equipment, and the environment.

However, HIPPS is not a shortcut or a replacement for good engineering practice. Its effectiveness depends on correct application, rigorous analysis, and strong lifecycle management. When used responsibly, HIPPS becomes a powerful and reliable safety solution in modern oil and gas facilities.

I hope you like above blog. There is no cost associated in sharing the article in your social media. Thanks for Reading !! Happy Learning