Table of Contents

ToggleHeat Tracing : Introduction

In industrial environments where temperature-sensitive fluids are transported, maintaining optimal temperatures within piping systems is crucial. Heat tracing emerges as a vital solution, offering protection against freezing and ensuring consistent fluid temperatures.

This article will explain intricacies of heat tracing in piping systems, exploring its types, applications, benefits, and installation considerations

What is Heat Tracing?

Heat tracing involves applying a controlled amount of heat to pipes, tanks, or vessels to maintain or raise their temperature. This is typically achieved by running heating elements along the length of the pipe, which are then insulated to retain the heat.

Types of Heat Tracing Systems

Electric Heat Tracing

Electric heat tracing systems utilize electrical cables that generate heat through resistance. These cables are affixed to the exterior of the pipes and are insulated to minimize heat loss. There are several subtypes:

- Self-Regulating Cables: These adjust their heat output based on the ambient temperature, reducing the risk of overheating.

- Constant Wattage Cables: Provide a uniform heat output along their length, suitable for applications requiring consistent temperatures.

- Mineral-Insulated Cables: Designed for high-temperature applications, these cables offer durability and are often used in harsh environments.

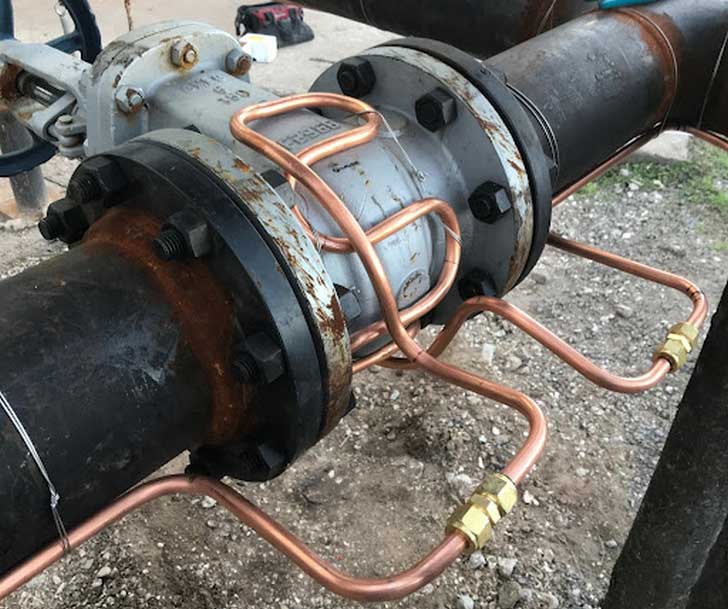

Fluid (Steam) Heat Tracing

Fluid heat tracing systems means circulating a heated fluid, commonly steam, through tubing that runs alongside the process pipes.

The heat from the fluid transfers to the pipe, maintaining the desired temperature. While effective, these systems can be more complex and require additional infrastructure for fluid circulation and condensation management.

Applications

Heat tracing finds applications across various industries:

- Freeze Protection: In colder climates, preventing the freezing of water lines, fire protection systems, and other critical pipelines is essential.

- Process Temperature Maintenance: Industries like chemical processing, oil and gas, and food production require specific temperatures to ensure product quality and process efficiency.

- Viscosity Control: For substances like heavy oils or syrups, maintaining a certain temperature ensures they remain fluid and easy to transport.

Condensation Prevention: In gas lines, maintaining temperatures above the dew point prevents condensation, which can lead to corrosion or blockages.

Benefits of Implementing Heat Tracing

- Keeps Operations Running: It stops pipes from freezing and keeps temperatures steady, so work doesn’t get interrupted.

- Improves Safety: It helps avoid pipe bursts and leaks caused by temperature changes, making the system safer for workers and equipment.

- Saves Energy: Modern heat tracing systems, like self-regulating cables, use only the energy needed by adjusting heat automatically.

- Reduces Costs: It cuts down on repair and maintenance costs and helps avoid losses from damaged products or system shutdowns.

- Keeps Fluids Flowing Right: It helps keep liquids at the right thickness or pressure, which is important for smooth and accurate processes.

- Protects Equipment: By reducing temperature stress, it helps pipes and equipment last longer.

- Works in Many Industries: Heat tracing can be used in many places like oil and gas, food factories, chemical plants, and more—it fits different needs easily.

Installation Considerations

Proper installation is important for the effectiveness of this systems:

- System Design: Factors like pipe material, ambient temperature, insulation type, and desired maintenance temperature must be considered.

- Cable Selection: Choosing the appropriate type of heating cable based on the application’s requirements is crucial.

- Insulation: Adequate insulation ensures minimal heat loss and enhances system efficiency.

- Control Systems: Implementing thermostats or advanced control units allows for precise temperature regulation and energy optimization.

- Regular Maintenance: Periodic inspections ensure the system’s integrity, identifying potential issues like insulation damage or cable wear.

Summary

Heat tracing is an important part of modern industries. It helps protect pipes from temperature problems like freezing or heat loss. By learning about the different types, uses, and how to install it properly, industries can use heat tracing effectively to improve safety, save energy, and keep operations running smoothly.

I hope you like above blog. There is no cost associated in sharing the article in your social media. Thanks for reading!! Happy Learning!!

1 Comment