Table of Contents

ToggleFloat Level Switch: Introduction

Understanding how we measure the level of liquids in tanks is very important for students in the instrumentation field. One common and simple device used for this is the Float Level Switch.

In this blog, we will explain:

- What is a float level switch?

- How does it work?

- Why is it used?

- Where is it used?

So, Let’s begin!

What is a Float Level Switch?

A Float Level Switch is a device used to detect the level of liquid in a tank or vessel. It tells us when the liquid is too high, too low, or at a specific level.

It works with the help of a float – a small object that floats on the surface of the liquid.

The Basic Principle – Buoyancy

What is Buoyancy?

Buoyancy means that when an object is placed in a liquid, the liquid pushes it up. This upward force is called the buoyant force.

The rule says: “The buoyant force on an object is equal to the weight of the liquid it pushes away (displaces).”

How does this apply to float switches?

A float is designed to stay partially above the liquid and partially below. As the liquid level rises or falls, the float moves up or down with it.

This movement is used to turn a switch ON or OFF depending on the level of liquid.

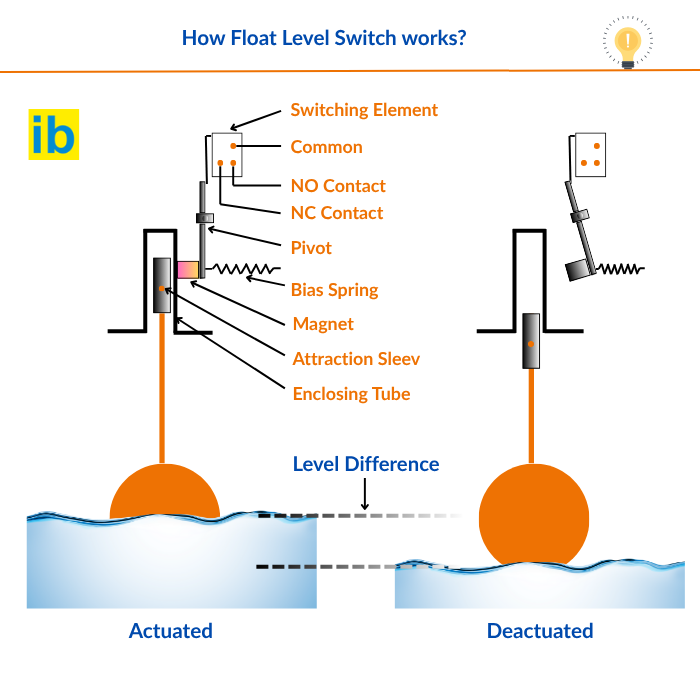

How Does a Float Level Switch Work?

Let us understand the working into simple steps:

1. Float on the Liquid Surface

- The float stays on top of the liquid.

- It rises when the liquid level rises.

- It falls when the liquid level drops.

2. Magnet Inside the Float

- Inside the float or inside a tube connected to the float, there is a magnet or magnetic sleeve.

- This magnet moves with the float.

3. Switch Activation

- Inside the tube or housing, there is an electrical switch (like a reed switch) or a pneumatic switch.

- When the float moves to a certain position (high or low), the magnet comes close to this switch.

- The magnetic field turns the switch ON (activates it).

- When the float moves away, the magnet goes away and turns the switch OFF (deactivates it).

So, the float movement controls the switch. This switch can be used to turn on an alarm, start/stop a pump, or send a signal to a control system.

Simple Example to Understand

Imagine you are filling water in a tank.

- At the low level, the float is at the bottom and the switch is OFF.

- As the water level rises, the float goes up.

- When the water reaches a set point, the float reaches the switch level.

- The magnet activates the switch → An alarm rings or a pump stops.

- When the water level drops again, the float goes down, the switch turns OFF, and the process repeats.

This is how a float level switch helps in monitoring and controlling liquid levels.

Types of Float Switch Applications

Float switches are mainly used for:

- High level alarm (to prevent overflow)

- Low level alarm (to avoid running dry)

- Pump control (start or stop based on level)

- Safety shutdown systems

They are not used for exact measurement, but to detect a level and act on it.

Float Level Switches Benefits

Here are some benefits of float level switches:

Simple Design

No complicated electronics. Just float and switch.

Reliable

Since it uses basic physics, it is dependable even in harsh environments.

Cost-effective

Cheaper than many other level sensors.

Works in High Temperatures

Many float switches can work in very hot liquids.

Customizable

You can have 1, 2, or even 3 switches in one float switch.

You can also use multiple floats to detect different levels.

Float Level Switches Applications

Float switches are used in many industries where liquids are stored, moved, or processed.

Here are some common places:

Power Plants

To monitor and control water, oil, or chemical levels in boilers, tanks, and pumps.

Petrochemical and Refinery Plants

Used in tanks and pressure vessels to avoid overfilling or emptying.

Chemical Plants

Helps in controlling the level of chemicals in storage tanks or reactors.

Paper and Pulp Mills

Used in tanks and sumps during the pulp washing and paper making process.

Sugar Mills

Helps control water and syrup levels in the refining process.

Ships and Marine Systems

Used in bilge tanks, fuel tanks, and ballast tanks.

Basically, float switches are used wherever liquids go in and out of tanks or vessels.

Important Things to Know about float level switches

1) Not for Wide Range: Float switches are not ideal for applications where level changes a lot and continuously. They are best for fixed level detection like high and low alarms.

2) Materials Matter: Floats are made from stainless steel, plastic, or other materials depending on the liquid type. Always choose a float material that suits your application (like corrosion resistance).

3) Mounting Position: Float switches can be mounted from the top, side, or bottom. Choose based on tank design.

4) Magnet Safety: Make sure no metallic particles are present in the liquid that can disturb the magnet function.

5) Maintenance: Simple to maintain, but regular cleaning is needed if the liquid is sticky or dirty.

Summary

Float level switches are simple, reliable, and cost-effective devices used to detect the level of liquids in tanks. They work on the buoyancy principle, and use the movement of a float to operate a magnetic switch.

For instrumentation students, it is important to understand:

- How float switches work

- Where they are used

- Their advantages and limitations

They are commonly used for level alarms, pump controls, and safety systems in many industries like power plants, chemical plants, refineries, and more.

Quiz Time! (For Revision)

Try to answer these:

1) What principle does a float level switch work on?

2) What happens when the float goes up?

3) Can a float level switch be used for exact level measurement?

4) Name any 3 industries where float switches are used.

5) Why are magnetic switches used inside float level switches?

I hope you like above blog. There is no cost associated in sharing the article in your social media. Thanks for reading!! Happy Learning!!