Table of Contents

ToggleDP Level Measurement: Introduction

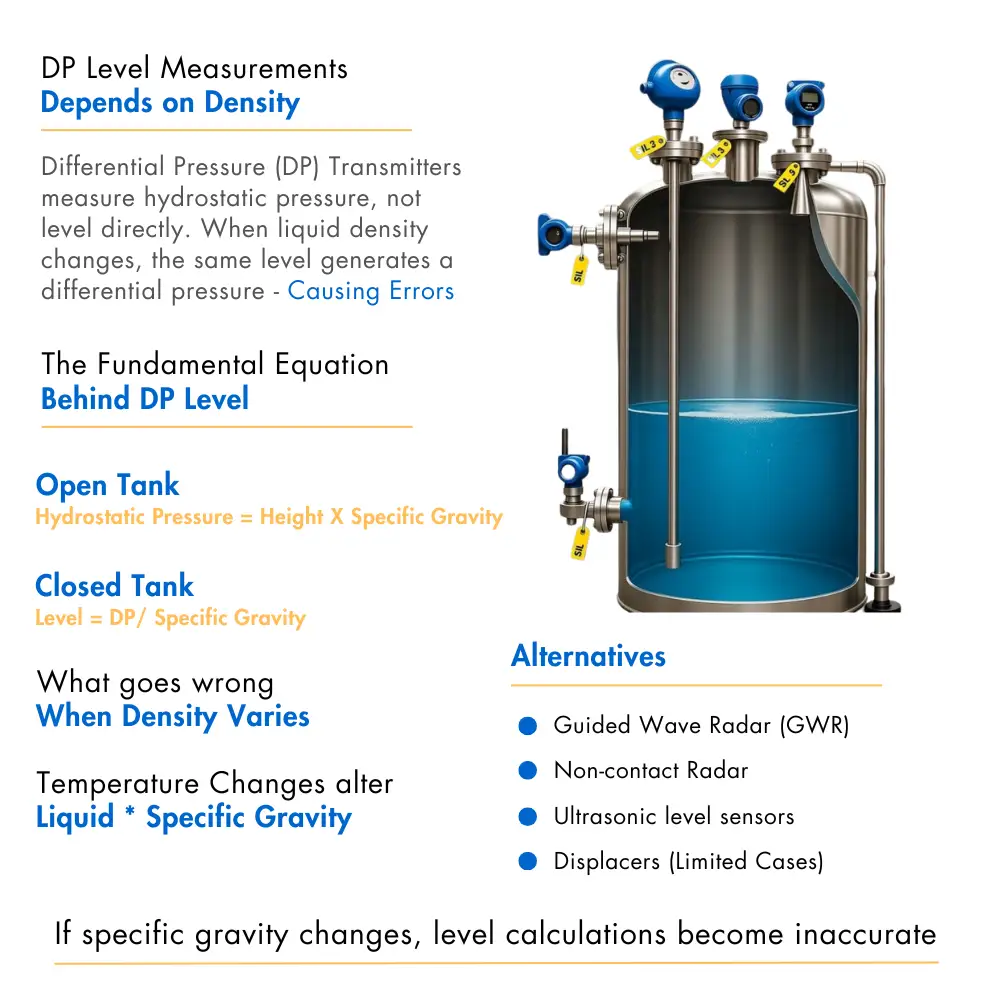

Differential Pressure (DP) transmitters have been used for decades to measure liquid level in industrial vessels. They are robust, familiar, and relatively easy to install. Because of this, DP level measurement is often the first choice in many projects.

However, DP level measurement comes with a major limitation that is often overlooked during design: it assumes that liquid density remains constant.

In real-world processes, density rarely stays constant. Temperature changes, chemical reactions, aeration, and composition variations can all cause density to fluctuate. When this happens, DP-based level measurement starts giving misleading results.

This article explains why DP Level Measurement fails in varying density applications and introduces 4 proven alternatives that work reliably when density cannot be controlled.

How DP Level Measurement Works

To understand the limitation, it is important to understand the basic principle behind DP level measurement.

DP transmitters do not measure level directly. They measure hydrostatic pressure, which depends on two factors:

Liquid height

Liquid density (specific gravity)

For an open vessel, the relationship is:

Hydrostatic Pressure = Height × Specific Gravity

For a closed vessel, the level is calculated as:

Level = Differential Pressure ÷ Specific Gravity

This means DP level measurement is only accurate if the specific gravity is known and constant. Any change in density directly affects the pressure reading, even if the actual liquid level remains unchanged.

The Fundamental Problem in Varying Density Applications

The main issue with DP Level Measurement is simple but critical:

DP transmitters cannot distinguish between a change in level and a change in density.

If density increases, the transmitter interprets it as a higher level.

If density decreases, the transmitter interprets it as a lower level.

This leads to incorrect level indication even though the physical level in the tank has not changed.

In many plants, operators try to solve this by recalibrating the DP transmitter frequently. Unfortunately, this only treats the symptom, not the root cause. As long as density keeps changing, the error will keep coming back.

Typical Applications Where DP Level Measurement Struggles

There are many industrial applications where liquid density naturally varies during operation. In such cases, DP level measurement becomes unreliable.

Some common examples include:

Chemical reactors, where concentration changes as the reaction progresses

Slurry tanks, where solids content varies with mixing and settling

Fermentation vessels, where biological activity changes density continuously

Heated vessels, where temperature gradients affect specific gravity

Interface level measurement, where composition changes over time

In all these cases, DP transmitters often cause false high or low level alarms, leading to operational confusion.

Operational Problems Caused by Incorrect DP Level Measurement

When DP Level Measurement is used in varying density applications, the impact goes far beyond a wrong number on the display.

Common consequences include:

Frequent false alarms that operators start ignoring

Unnecessary shutdowns or overfills

Increased calibration and maintenance effort

Loss of confidence in instrumentation readings

Poor process control and product quality issues

Over time, this can result in higher operating costs and reduced plant reliability.

Why Installation Quality Cannot Fix Density Errors

A common misconception is that careful installation can solve DP level problems.

Yes, good practices like correct impulse line slope, proper tapping location, and impulse line flushing are important. They prevent plugging, condensation, and response delay.

However, no installation improvement can eliminate density dependency.

Even a perfectly installed DP transmitter will still give wrong readings if density changes. This is a limitation of the measurement principle itself, not the hardware.

Alternative 1: Guided Wave Radar (GWR)

Guided Wave Radar is one of the most reliable alternatives to DP Level Measurement in varying density applications.

GWR works by sending electromagnetic pulses along a probe. These pulses reflect back from the liquid surface. The level is calculated based on the travel time of the signal, not on pressure or density.

Because of this, GWR is largely independent of:

Density changes

Temperature variations

Pressure fluctuations

GWR performs extremely well in reactors, separators, and vessels with foam or vapor. This makes it a proven replacement for DP transmitters in many critical applications.

Alternative 2: Non-Contact Radar Level Measurement

Non-contact radar level measurement uses high-frequency microwave signals transmitted from the top of the tank toward the liquid surface.

Since radar measures distance, it does not rely on liquid density. As a result, it is unaffected by changes in specific gravity.

Non-contact radar is especially suitable for:

Large storage tanks

Corrosive or aggressive liquids

High-temperature or high-pressure applications

Because there is no physical contact with the process, maintenance requirements are also minimal.

Alternative 3: Ultrasonic Level Sensors

Ultrasonic level sensors measure level by sending sound waves toward the liquid surface and measuring the echo time.

Like radar, ultrasonic level measurement is distance-based, not pressure-based. Therefore, density variations do not directly affect the measurement.

Ultrasonic sensors work best in:

Open tanks

Atmospheric vessels

Clean liquid applications

However, they can be affected by heavy vapors, foam, or turbulence. When process conditions are stable, ultrasonic sensors offer a simple and cost-effective alternative to DP level measurement.

Alternative 4: Displacer Level Measurement

Displacer level measurement is based on buoyancy rather than hydrostatic pressure.

A displacer experiences an upward force proportional to the weight of displaced liquid. This force changes with level.

Displacers can tolerate limited density variation if the change is predictable and compensation is applied. However, they are not ideal for applications with rapid or unpredictable density changes.

Displacers are best suited for:

Stable processes

Narrow operating ranges

Applications with known density profiles

Making the Right Technology Choice

The most important lesson is this:

Level measurement technology must match process behavior, not tradition.

DP Level Measurement works well only when density is stable. When density varies, DP transmitters will always provide misleading readings, no matter how well they are installed or maintained.

Choosing a density-independent technology from the beginning:

Reduces calibration frequency

Improves measurement reliability

Lowers maintenance costs

Prevents false alarms and process disruptions

What We Learn Today?

DP Level Measurement is not wrong but it is simply misapplied in many modern processes.

As processes become more complex, dynamic, and variable, relying on pressure-based level measurement becomes risky.

When density varies, technologies like Guided Wave Radar, Non-Contact Radar, Ultrasonic sensors, and Displacers provide more reliable and accurate results.

Selecting the right level measurement technology is not about familiarity. It is about understanding your process and choosing a principle that truly fits the application.

I hope you like above blog. There is no cost associated in sharing the article in your social media. Thanks for Reading !! Happy Learning