Table of Contents

ToggleDifferential Pressure Gauge: Introduction

In industrial instrumentation, measuring pressure is very common. But in many real applications, engineers are not interested in a single pressure value.

Instead, they need to know the difference between two pressures. This is exactly where a Differential Pressure Gauge (DP Gauge) becomes an essential instrument.

From filter monitoring and flow measurement to cleanroom safety and level measurement, differential pressure gauges are widely used across industries like oil & gas, power plants, pharmaceuticals, HVAC, water treatment, and chemical processing.

In this article, we will explain the working principle, construction, applications, advantages and FAQs of a differential pressure gauge in a very easy way.

What is a Differential Pressure Gauge?

A Differential Pressure Gauge is an instrument used to measure the difference between two pressures applied at two different points of a system.

It always has:

- One High-Pressure (HP) connection

- One Low-Pressure (LP) connection

The gauge does not measure absolute pressure. It only shows the difference between P1 and P2.

Differential Pressure = P2 – P1

If both pressures are equal, the gauge shows zero reading.

Basic Working Principle of a Differential Pressure Gauge

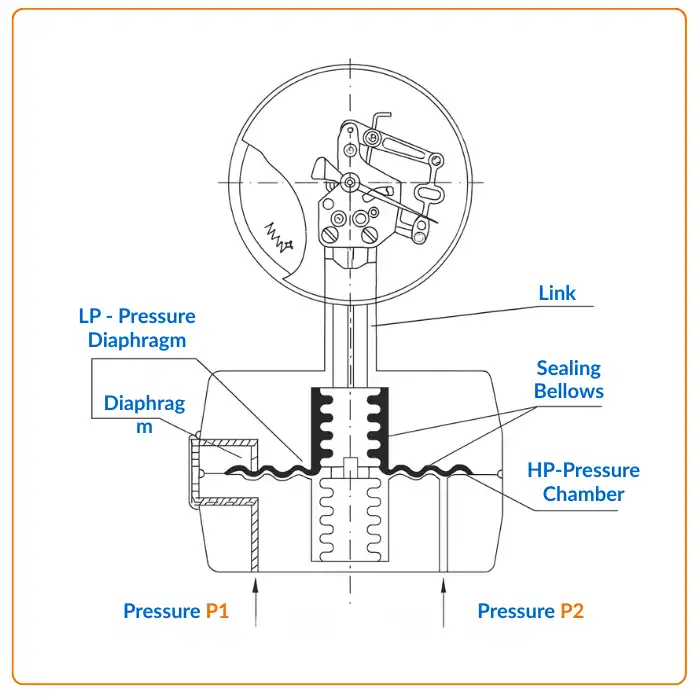

The working principle of a differential pressure gauge is based on the force created by pressure acting on a flexible sensing element. This sensing element can be a diaphragm, capsule, bellows, or a Bourdon tube in high-pressure designs.

Two different pressures, P1 and P2, are applied on opposite sides of this sensing element. When both pressures are equal, the forces balance each other and the element does not move, so the gauge shows zero reading. When one pressure becomes higher than the other, an imbalance is created and the sensing element starts to move toward the lower-pressure side.

This very small mechanical movement is then amplified using levers and gear mechanisms inside the gauge. The amplified motion rotates the pointer on the dial, and the scale directly shows the differential pressure between the two points.

Main Parts of a Differential Pressure Gauge

A typical mechanical DP gauge consists of the following components:

- High-pressure chamber

- Low-pressure chamber

- Flexible diaphragm

- Sealing bellows

- Mechanical link and gear system

- Pointer and dial mechanism

Each of these components works together to convert pressure difference into a visible mechanical indication.

Step-by-Step Working of a Differential Pressure Gauge

Let us understand the complete working in a simple sequence:

1) Pressure Entry

P1 enters the low-pressure side.

P2 enters the high-pressure side.

2) Pressure Acts on Diaphragm

Both pressures apply force on opposite sides of the diaphragm.

3) No Pressure Difference

If P1 = P2 → forces balance → diaphragm remains steady → pointer stays at zero.

4) Pressure Difference Occurs

If P2 becomes more than P1 → diaphragm bends towards the low-pressure side.

5) Movement Transmission

The diaphragm movement is transmitted through:

Linkages

Levers

Gears

6) Pointer Movement

The gear system moves the pointer on the dial.

The scale directly shows the differential pressure value.

7) Overload Protection

Sealing bellows protect the instrument from high static pressure and pressure surges.

Why Differential Pressure Can Be Measured at High Static Pressure

One important feature of DP gauges is that they can measure very small pressure differences even when both sides have high pressure.

Example:

- P1 = 80 bar

- P2 = 79.7 bar

- Differential Pressure = 0.3 bar

Even though the system pressure is very high, the gauge only responds to the difference, not the total pressure. This is possible because the internal design balances the static pressure on both sides.

Types of Measuring Elements Used in DP Gauges

Different measuring elements are used in differential pressure gauges based on the application, working pressure, and required sensitivity. The most commonly used element is the diaphragm, which is highly sensitive and ideal for low differential pressure measurement.

For very small pressure differences, especially in cleanroom and HVAC applications, the capsule type measuring element is preferred. Bellows-type elements are used in medium differential pressure ranges where good mechanical strength and stable performance are required.

For high-pressure differential applications, the Bourdon tube type element is used due to its ability to withstand rugged industrial conditions.

In short:

- Diaphragm: Low DP, high sensitivity

- Capsule: Very low DP, cleanroom & HVAC

- Bellows: Medium DP, strong construction

- Bourdon Tube: High DP, heavy industrial use

Frequently Asked Questions (FAQs)

Q1. Why is a differential pressure gauge required?

It is required to measure flow, detect filter choking, ensure cleanroom safety, measure tank level, and monitor pump performance.

Q2. How does a DP gauge work in simple words?

It compares two pressures using a diaphragm. Any difference causes movement, which is converted into pointer movement on the dial.

Q3. Can DP gauges measure gas flow?

Yes. Differential pressure gauges are widely used for both gas and liquid flow measurement.

Q4. What happens when both pressures are equal?

When both pressures are equal, the diaphragm does not move and the gauge shows zero reading.

Q5. What is the typical accuracy of a DP gauge?

Mechanical DP gauges usually have an accuracy of ±1.6% to ±2.5% of full scale.