- July 31, 2025

Anti Surge Controller Systems: In instrumentation industry, Centrifugal compressors are widely used in industries like oil & gas, petrochemicals, and air separation.

One serious problem these compressors face is surge, which is a repeating instability that can damage the machine and disrupt operations.

Surge controllers (or anti‑surge controllers) are safety devices that protect compressors from this harmful condition.

Table of Contents

ToggleSurge is an aerodynamic instability that happens when compressor flow drops too low and the discharge pressure becomes higher than the compressor can sustain.

This causes reversed flow, loud noise, rapid temperature rises, and severe vibration.

Over time, repeated surges can damage bearings, seals, rotor blades, and even shut down the system.

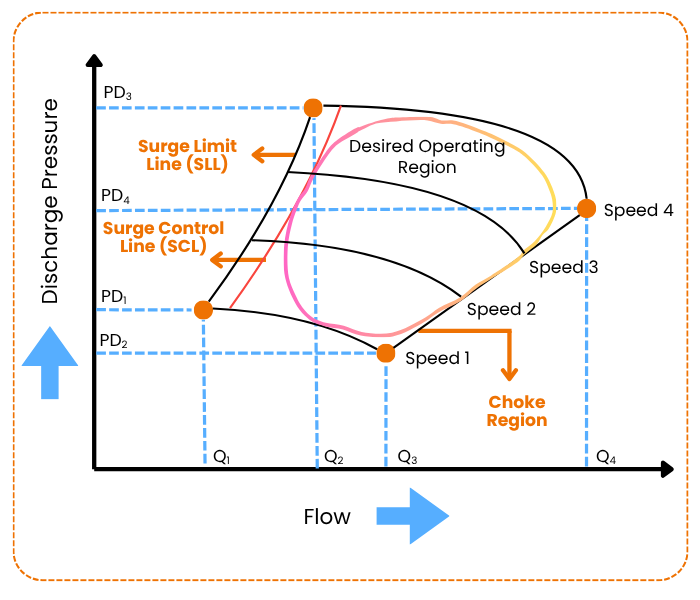

If you look at the compressor map, then there is a line on that map called the surge limit line (SLL). If compressor operation crosses that line on the left (lower flow), the compressor begins to surge. Operators want to run the compressor on the right side of this line, ideally with a margin for safety

Even small fluctuations in upstream/downstream flow or demand can push a compressor into surge. Traditional process controllers are often too slow or too general to react in time. An anti surge controller is dedicated and fast‑acting, built to recognize and avoid surge conditions in real time.

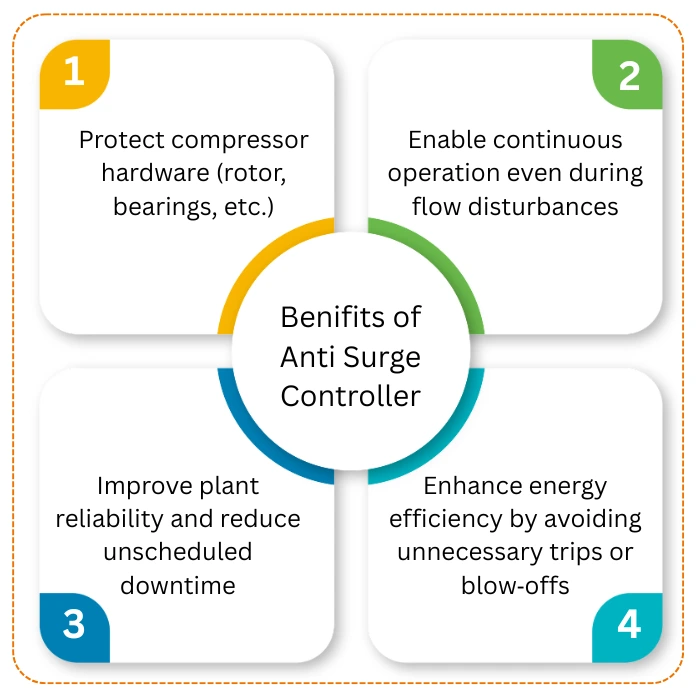

These systems offer several benefits:

These readings help calculate how close the compressor is to the surge line, adjusting in real‑time for changing gas conditions or ambient temperatures

Based on the compressor’s performance map, the Anti Surge Controller defines:

With the flow dropping too close to SCL, the controller modulates a valve (the anti‑surge or recycle valve) to route discharge gas back to suction. This increases the internal flow and pushes the operating point back into a safe zone.

The valve must be fast responding (0.5 to 2 seconds to stroke fully), well sized, and usually in “fail‑open” position so that loss of power or signal defaults to the safer open state.

It is installed close to the compressor discharge to reduce control lag

Sizing is critical:

A typical sizing ratio is ~1.8 to 2.2 × the worst-case flow required at the surge condition. Valves are often linear or equal-percentage type and must include noise‑reducing trim because of high differential pressures

Most anti surge controllers use PI loops, sometimes with derivative control, especially when fast corrections are needed. Proportional control is preferred near the SCL for quick response; integral action helps maintain stable control over time.

Manual override and bumpless transfer between auto and manual modes are standard features.

The system must also include fallback strategies in case of sensor or signal failures—keeping the compressor in a safe flow region, or shutting it down if needed

The surge line may shift due to variations in gas composition, suction conditions, temperature, or speed. Advanced controllers (like Petrotech’s EM‑400 or adaptive systems) automatically recalibrate the surge line and setpoint margins to maintain protection accuracy under variable conditions

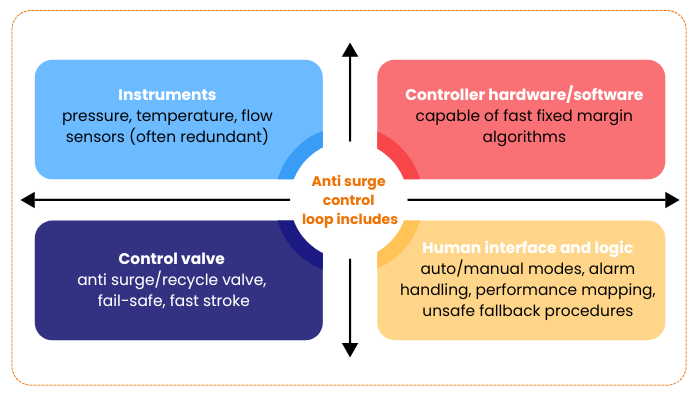

A typical anti surge controller loop includes:

Petrotech Inc. delivers stand‑alone surge controllers like the EM‑400, capable of handling multi‑compressor systems, adaptive gain, performance mapping, capacity control, and built-in display logic for monitoring surge proximity and process state transitions.

A complete system to monitor, adjust, and protect at all times

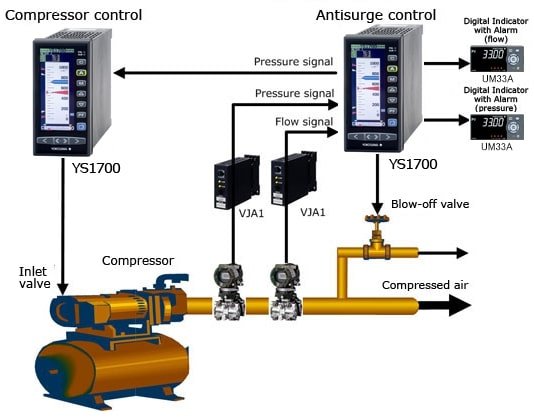

Yokogawa’s YS1700 single‑loop controller seamlessly switches between flow and pressure control to avoid surge in operation. Their solutions (such as CCC Inside for CENTUM VP systems) integrate proven anti‑surge logic, load‑sharing, and speed control modules into DCS/FCS platforms, suitable for centrifugal or axial compressors

In simple terms:

With these systems in place, centrifugal compressors can run efficiently, safely & continuously, even during rapid changes in process conditions which avoids costly shutdowns & mechanical damage.

I hope you like above blog. There is no cost associated in sharing the article in your social media. Thanks for reading!! Happy Learning!!

1 Comment