Table of Contents

ToggleCalculate Pressure Drop: Introduction

When a fluid flows inside a pipeline, it does not move without resistance.

As it touches the pipe walls, passes around bends, or flows through valves and fittings, a part of its pressure is lost.

This reduction in pressure is known as pressure drop.

Understanding pressure drop is very important for students, technicians and engineers in the instrumentation and fluid mechanics field.

It affects energy consumption, pump sizing, fluid flow rate, and even the overall efficiency and lifespan of the system.

You may also refer my article on How to Calculate Heat Loss in Piping.

In this article, we will understand the concept of pressure drop in simple terms, discuss where it occurs, how to calculate it and why it matters in real-world applications.

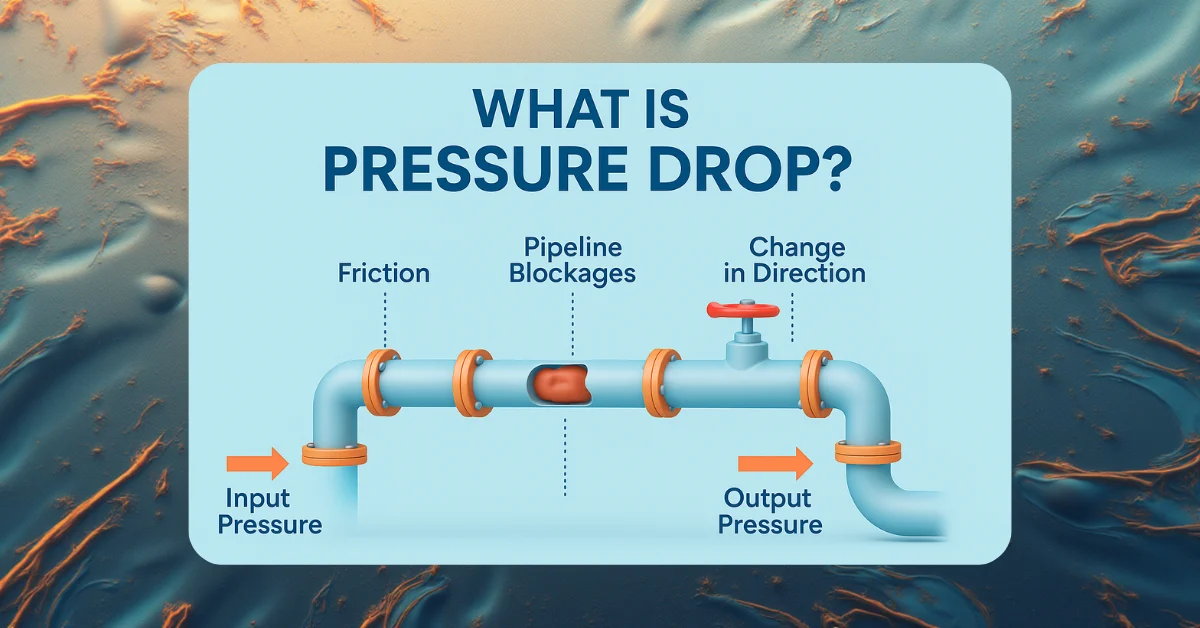

What Is Pressure Drop?

Pressure drop is the decrease in fluid pressure as it flows through a pipe, valve, or any flow-related component.

Pressure drop can occur due to several reasons:

1) Friction between the fluid and the inner surface of the pipe

2) Sudden direction changes (like elbows, bends, tees)

3) Pipeline blockages such as dirt, scale, or partially closed valves

4) Changes in pipe diameter

5) Obstructions like filters and strainers

In simple words:

The more the fluid has to “struggle” to move forward, the higher the pressure drop.

Why Is Pressure Drop Significant?

Pressure drop is more than just a number but it provides critical information about how healthy and efficient a system is.

1. Detecting Faults in a Pipeline

A sudden increase in pressure drop can indicate:

- A blockage or sediment build-up

- A valve that is accidentally (or partially) closed

- A possible leak

This makes pressure drop a useful diagnostic tool.

2. Ensuring Proper Heating or Cooling

In HVAC or hot-water systems, valves regulate temperature by controlling flow.

If the pressure drop across the valve is too high, the system may fail to deliver the required flow—leading to poor heating or cooling performance.

3. Correct Valve Sizing

Pressure drop calculations are critical for sizing valves:

- Oversized valve → Too much flow → Faster wear and poor control

- Undersized valve → Excessive pressure drop → Higher energy use

4. Predicting Pump Power Requirements

Higher pressure drop means the pump must work harder, which increases:

- Power consumption

- Operating cost

- Pump maintenance needs

5. Planning Maintenance

Monitoring pressure drop over time helps maintenance teams plan cleaning, inspections, or filter replacement.

Pressure loss mainly means a drop in the static pressure or total pressure of the fluid.

The dynamic pressure and hydrostatic pressure do not change because of energy losses they depend only on how the pipeline is shaped and arranged.

Additional pressure losses happen in different parts of the system, such as valves, elbows, or measuring devices.

Static pressure loss in pipelines happens because some mechanical energy is always lost when a fluid moves through a pipe system.

How to Calculate Pressure Drop (Darcy Weisbach Equation)

The Darcy Weisbach equation is the most widely used formula for calculating pressure drop in pipes.

Where:

- ΔP = Pressure drop (Pa)

- f = Darcy friction factor

- L = Length of pipe (m)

- D = Pipe diameter (m)

- ρ (rho) = Fluid density (kg/m³)

- V = Flow velocity (m/s)

The friction factor f depends on:

- Whether the flow is laminar or turbulent

- Pipe roughness

- Fluid velocity

It is usually obtained from charts, formulas, or software.

Pressure Drop Example

Calculate the pressure drop for water flowing through a 120 m long pipe with a diameter of 0.12 m.

Assume:

- f = 0.028

- Velocity (V) = 25 m/s

- Density ρ = 1000 kg/m³

Insert values into the Darcy Weisbach equation

This is a very high pressure drop, means:

- Stronger pipes and fittings are required

- Pump must deliver much higher pressure

- Energy consumption increases significantly

This is why calculating pressure drop early in the design stage is essential.

Pressure Drop in Fittings (Minor Losses)

In long pipelines, most pressure drop comes from straight-pipe friction.

But fittings also add losses, called minor losses.

Examples of fittings that create minor losses:

- Elbows

- Tees

- Valves

- Reducers

- Bends

Equivalent Length Method

Each fitting is assigned an equivalent length, which represents how much straight pipe it behaves like.

Example:

- A 0.05 m diameter elbow

- Equivalent length = 25 × pipe diameter

- So equivalent length = 25 × 0.05 = 1.25 m

Now you treat this elbow as if it were 1.25 m of straight pipe and apply the Darcy–Weisbach formula.

If the flow velocity is 2.5 m/s and the friction factor is 0.026, the pressure drop may come around 1.2–1.6 kPa depending on density and conditions.

Individually these losses seem small but in systems with many bends and valves, they add up quickly.

Pressure Drop vs Flow Rate (Cv or Kv)

Valves have a flow coefficient called Cv (US units) or Kv (metric).

It indicates how easily a valve allows fluid to pass.

- Higher Cv → Lower pressure drop → High flow

- Lower Cv → Higher pressure drop → Restricted flow

Choosing the right valve size is important:

- A small valve restricts flow, causing high pressure drop

- A large valve reduces control accuracy

So, valve selection is always a balance between flow capacity and control need.

Pressure Drop in Different Applications

Pressure drop is not limited to pipes. It appears in several situations.

1. Pressure Drop Across an Orifice

When fluid passes through a small opening, it speeds up and then slows down. This rapid change causes a measurable pressure drop, used in orifice flow meters.

2. Pressure Drop Across Valves

Different valve types (ball, gate, globe, butterfly) cause different levels of resistance.

Globe valves typically cause higher pressure drop, while ball valves cause less.

3. Pressure Drop per 100 ft of Pipe

Used in water supply design. It varies with:

- Pipe material

- Diameter

- Water velocity

- Temperature

4. Filter Pressure Drop

Filters create resistance as they trap particles. A rising pressure drop usually means the filter is getting clogged and needs replacement.

FAQs – Pressure Drop in Pipes and Valves

1. What is pressure drop in simple words?

Pressure drop is the loss of pressure that happens when a fluid flows through a pipe, valve, bend, filter, or any flow-related component. It mainly occurs due to friction and resistance inside the system.

2. Why does pressure drop occur in pipelines?

Pressure drop occurs due to friction between the fluid and pipe walls, changes in direction (like elbows and bends), sudden changes in pipe size, obstructions, and restrictions such as valves or filters.

3. How does pressure drop affect pump performance?

Higher pressure drop means the pump must work harder to maintain the required flow. This increases power consumption, operating cost, and the overall strain on the pump.

4. How can I reduce pressure drop in a piping system?

You can reduce pressure drop by increasing pipe diameter, reducing flow velocity, minimizing the number of fittings, using smoother pipe materials, cleaning clogged filters, and ensuring valves are fully open when needed.

5. Is pressure drop always a bad thing?

No. Some pressure drop is normal and necessary for example, to control flow through valves. However, excessive pressure drop indicates inefficiency, blockage, or improper sizing of piping components.

6. What is the difference between major and minor losses in pressure drop?

6.1) Major losses come from friction in long, straight pipe sections.

6.2) Minor losses occur due to fittings like elbows, tees, valves, reducers, and filters.

In long pipelines, major losses dominate. In short, compact systems, minor losses may become more significant.

7. How does pipe diameter influence pressure drop?

Larger pipe diameters reduce fluid velocity and friction, resulting in lower pressure drop. Smaller pipes increase velocity, causing higher friction and a larger pressure drop.

I hope you like above blog. There is no cost associated in sharing the article in your social media. Thanks for Reading !! Happy Learning