- July 10, 2025

In industrial automation, wiring errors can cause huge issues: incorrect readings, communication failures, equipment damage, and even safety risks.

That’s why standard cable color codes and wiring practices are very important for reliable operation & faster troubleshooting.

This guide will help technicians, engineers, and students understand the most common wiring color codes and how to apply them during installation, loop checks, and maintenance.

Table of Contents

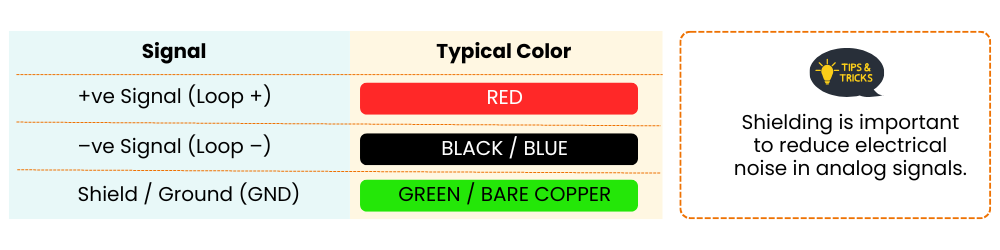

ToggleAnalog signals are the traditional way to transmit process values like pressure, temperature, level, or flow between field instruments and control systems.

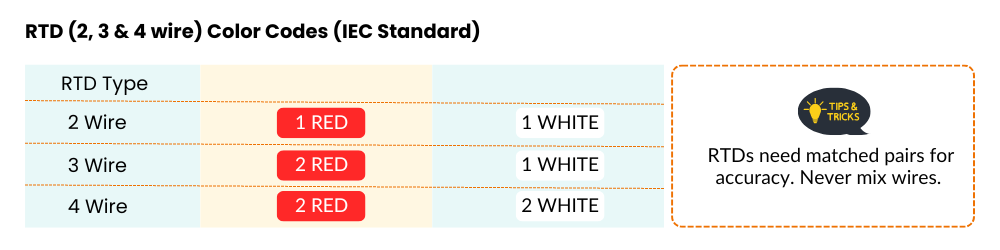

RTD stands for Resistance Temperature Detector. It measures temperature by detecting the resistance change in a metal (usually platinum).

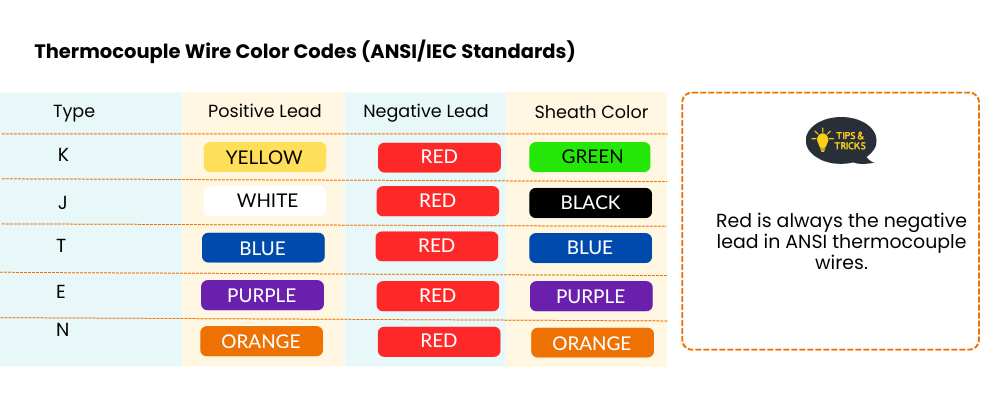

A thermocouple uses two different metals joined at one end to create a temperature-dependent voltage.

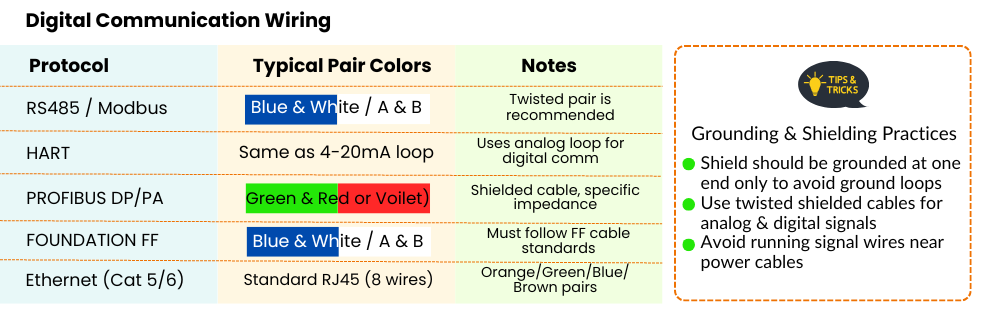

Digital protocols are used for smart transmitters, controllers, and remote monitoring systems. They carry both data and device diagnostics.

Grounding and shielding protect signals from electromagnetic interference (EMI) and help prevent false readings or system faults.

🧷 Label Everything

Always label both ends of every cable – saves time during maintenance and avoids mix-ups.

📐 Follow Project Drawings

Stick to wiring diagrams and termination schedules. If unsure, ask — don’t guess.

📸 Document Your Work

Take photos of the terminal blocks before closing the junction box or panel. It helps during future servicing.

⚠️ Check Before Powering Up

Use a multimeter to verify correct polarity, loop continuity, and grounding before energizing instruments.

Correct cable color coding and wiring practices are the backbone of a stable, accurate, and safe instrumentation system. Whether you are a technician doing a new install or an engineer troubleshooting a field device, following proper standards saves time and prevents costly mistakes.

📌 Bookmark or print this guide. Better wiring starts with better knowledge.

I hope you like above blog. There is no cost associated in sharing the article in your social media. Thanks for reading!! Happy Learning!!