Table of Contents

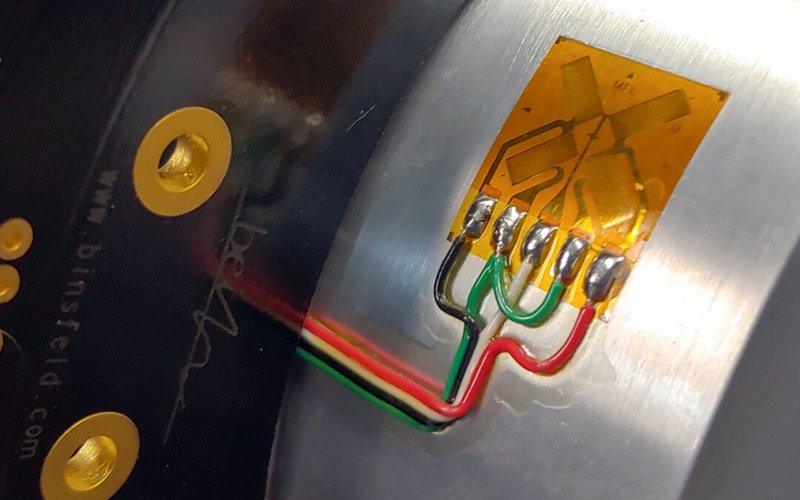

ToggleBonded and Unbonded strain gauges: Introduction

In this article, we will learn the difference between bonded and unbonded strain gauges, two common types of devices used to measure strain. But before we learn the differences, let us first understand the basic working principle of strain gauges and why they are so widely used.

What is a Strain Gauge?

A strain gauge is a device used to measure strain (or deformation) in a material when it is subjected to force or pressure.

The basic idea is very simple: when a material is stretched or compressed, its electrical resistance changes. Strain gauges works on the same principle.

These devices are used in many applications such as:

1) Measuring pressure in pressure transmitters

2) Monitoring weight in weighing machines

3) Checking strain and stress in structures like bridges, buildings, and machine parts

How Does a Strain Gauge Work?

The operation of a strain gauge is based on electrical resistance. When a material (like a metal wire or foil) is stretched, it becomes longer and thinner, which increases its resistance. When it is compressed, it gets shorter and thicker, and its resistance decreases.

This change in resistance is measured using a Wheatstone bridge circuit, which converts the small changes in resistance into electrical signals. These signals can then be further processed to give a pressure or strain reading.

To make these measurements more stable and accurate, modern strain gauge systems also include electronics that:

1) Compensate for temperature changes

2) Adjust the zero level

3) Calibrate the measurement range (span)

What are different types of Strain Gauges?

There are two main types of strain gauges based on their construction:

Unbonded Strain Gauges

Bonded Strain Gauges

Now we will understand each of them in detail and see how they are different from one another.

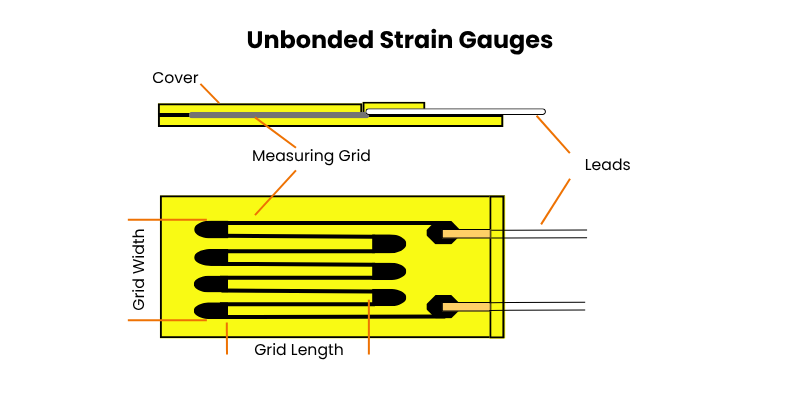

What is Unbonded Strain Gauge?

Working Principle

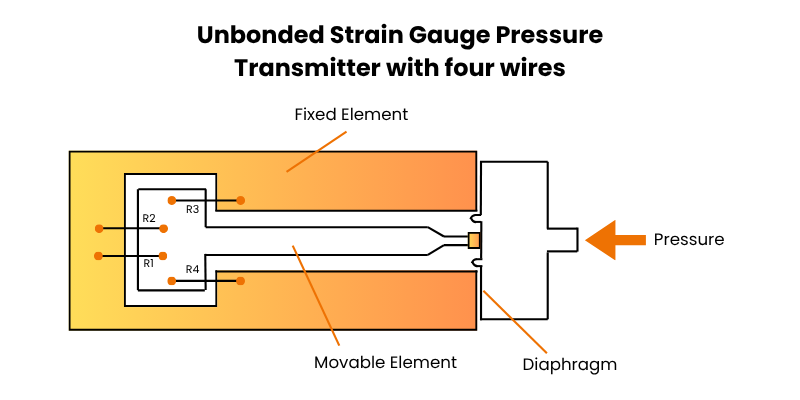

An unbonded strain gauge has a special frame that includes both stationary and movable parts. Very thin wires (about 0.4 mils in diameter) are stretched between these parts and wrapped around non-conductive posts.

When pressure is applied, the movable part shifts, pulling or relaxing the wire. This action changes the length and tension in the wire, which results in a change in its electrical resistance. The change in resistance is then measured using the Wheatstone bridge circuit and converted into a pressure reading.

Some designs use four wires—two experience tension and two experience compression. This improves accuracy.

Advantages of Unbonded Strain Gauges

- Can handle mechanical overpressure through built-in overtravel protection

- Have low mass, which helps in fast response

- Offer good long-term stability

Disadvantages of Unbonded Strain Gauges

- Sensitive to mechanical shocks

- May be less rugged compared to bonded types

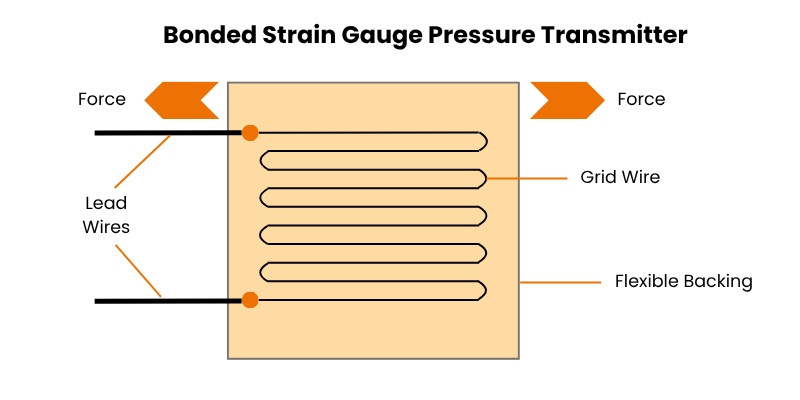

What is Bonded Strain Gauge?

Working Principle

In a bonded strain gauge, a thin foil or wire is glued (bonded) directly to a flexible diaphragm. When pressure is applied, the diaphragm bends slightly, and this movement causes the bonded wire or foil to stretch or compress, changing its resistance.

Usually, four strain gauges are placed on the diaphragm:

- Two near the center (to measure tangential strain)

- Two near the edges (to measure radial strain)

This placement helps improve accuracy and eliminates the need for posts or frames, making the design simpler and more compact.

Advantages of Bonded Strain Gauges

- More rugged and durable

- Better resistance to shock and vibration

- Compact design without moving parts

Disadvantages of Bounded Strain Gauges

- Limited to specific pressure and temperature ranges

- Might not be as long-lasting in extreme environments

Comparison Table: Bonded vs. Unbonded Strain Gauges

| Feature | Bonded Strain Gauge | Unbonded Strain Gauge |

|---|---|---|

| Construction | Foil or wire bonded to a diaphragm | Wire mounted between movable and fixed parts |

| Response to Pressure | Diaphragm flexes to strain the gauge | Movable part displaces to strain the wire |

| Accuracy | High, especially in vibration-prone areas | Moderate, can be affected by shock |

| Shock Resistance | Good | Poor |

| Overpressure Protection | Limited | Built-in overtravel stops available |

| Size and Weight | Compact and lightweight | Slightly larger due to frame and posts |

| Applications | Industrial pressure sensors, robust environments | Lab setups, precise systems with protection |

| Cost | Generally higher | Often lower |

What we learn today?

Both bonded and unbonded strain gauges work on the same basic principle — change in resistance due to stretching or compression. Their construction and performance differ based on how they are made and where they are used.

- Use unbonded strain gauges when you need better overpressure protection but are not dealing with mechanical shocks.

- Choose bonded strain gauges when you want a more rugged and shock-resistant solution with reliable performance in industrial conditions.

If you understand these differences then it will helps you select the right type of strain gauge based on your application in industrial pressure measurement.

I hope you like above blog. There is no cost associated in sharing the article in your social media. Thanks for reading!! Happy Learning!!