Table of Contents

ToggleOrifice Flow Meter Flange Ratings: Introduction

In industrial flow measurement, orifice plates and orifice flanges play an important role. They are simple, reliable and widely used devices to measure the flow rate of liquids, gases, or steam in pipelines.

But if you have ever looked into the design standards, you might have noticed something interesting restriction orifice plates can use 150# flanges, but orifice flow meter flanges are generally not recommended for 150# rating.

Why this difference?

Let us understand it in a simple and technical way.

What is an Orifice Flange or Flow Meter Flange?

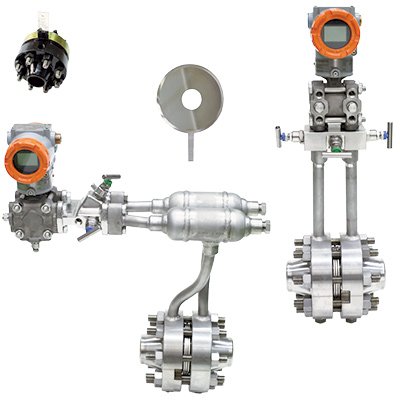

An orifice flange is a pair of specially designed flanges used to hold an orifice plate between them. This setup creates a pressure drop across the plate, which is then measured using a differential pressure transmitter to calculate the flow rate.

Unlike standard pipe flanges, an orifice flange has pressure tapping holes drilled into its body one on the upstream side and another on the downstream side. These holes allow pressure lines to connect directly to the transmitter.

So, in simple terms:

A Flow Meter Flange (Orifice Flange) = Standard flange + pressure tapping holes + jacking screws + provision for orifice plate installation.

Relevant Standards

There are two main flange standards used in piping design:

-

ASME B16.5 – Pipe Flanges and Flanged Fittings

Used for standard pipe flanges (weld neck, slip-on, socket weld, etc.) available in pressure classes 150#, 300#, 600#, 900#, 1500#, and 2500#. -

ASME B16.36 – Orifice Flanges

This is a dedicated standard for flanges that include pressure taps for orifice plates. It defines dimensions, tolerances, and pressure-temperature ratings.

Here is the key fact:

ASME B16.36 (for orifice flanges) starts from Class 300# — there is no 150# rating listed for orifice flanges in this standard.

That alone is a strong indicator that the industry and code committees do not recommend using 150# orifice flanges for flow measurement.

Why Is the 150# Orifice Flange Not Recommended?

Let’s explore the engineering logic behind this.

Flange Integrity – The Main Reason

The number one reason is flange integrity.

When you drill pressure tapping holes into a flange, its mechanical strength decreases because some metal is removed from a high-stress area.

In a Class 150 flange, the wall thickness is relatively small compared to higher classes. Adding drilled holes for pressure taps further reduces its ability to safely withstand design pressure and temperature.

Hence, there is a risk that a 150# flange may deform or leak under pressure after being modified for an orifice plate installation.

In simple terms:

“Orifice flanges have reduced strength due to drilled pressure taps, so a higher rating (300# or more) ensures safety.”

Pressure–Temperature Rating Becomes Unreliable

Every flange rating (150#, 300#, etc.) corresponds to a maximum allowable pressure at a given temperature.

For example, a 150# carbon steel flange can handle around 19 bar at 100°C, while a 300# flange can handle up to 50 bar at the same temperature.

When you machine pressure taps and holes, the effective pressure rating of the flange decreases slightly but this reduction is not quantified for 150# orifice flanges, because the ASME standard doesn’t define it.

That means there is no guaranteed safe rating for a 150# orifice flow meter flange.

Extra Machining Weakens the Flange

A complete orifice flow meter flange assembly includes:

- Two flanges with pressure tapping holes

- Jacking screws for easy removal of the orifice plate

- A gasket between the flanges

- Bolts and nuts tightened to high torque

These additional drilled holes and jacking screw slots remove metal and create stress concentration points.

In 150# flanges (which are thinner), this can compromise sealing and cause bending or leakage under load.

That is why manufacturers prefer starting from 300# class, it provides enough thickness to safely accommodate these features.

Compliance with ASME B16.36

The ASME B16.36 standard itself supports this recommendation.

It lists orifice flange classes starting from 300# and goes up to 2500#.

If you specify a 150# orifice flange, you are technically outside the scope of ASME B16.36, meaning it would have to be a non-standard design which adds design risk, cost, and certification complications.

In opposite, a Restriction Orifice (RO) plate which does not have any pressure taps follows ASME B16.5, and hence 150# flanges are perfectly acceptable for that application.

Industry Practice and Field Experience

Over the years, engineers have noticed that orifice flow meter flanges built with 150# rating are prone to:

- Minor leaks near the pressure tapping holes,

- Distorted flanges after repeated tightening, and

- Alignment issues during maintenance or plate replacement.

Therefore, the best practice evolved to always use Class 300 or higher for orifice flow meter installations.

Are There Any Exceptions?

Yes, but they are rare.

Some engineers mention that for very large pipelines (say, above 10” to 20”), a 150# flange may still have sufficient thickness and strength, because the metal cross-section increases with size.

However, this exception:

- Must be verified by detailed mechanical analysis, and

- There is no specific proof or allowance for this in ASME B16.36.

So, unless a stress analysis or vendor certification explicitly confirms it, stick with Class 300 or higher.

ASME B16.5 Class 150 flanges below 500 NB do not offer adequate space to accommodate ½-inch pressure tapping connections.

Hence, dedicated ASME B16.36 orifice flanges or an orifice carrier ring assembly shall be used for proper tapping arrangement and accurate differential pressure measurement.

What we learn today?

Choosing the right flange rating may look like a small detail, but it directly affects safety, reliability, and measurement accuracy.

When designing or specifying flow measurement systems, always ensure your orifice flanges comply with ASME B16.36 and use Class 300 or higher.

This not only ensures code compliance but also guarantees long-term leak-free and safe operation in the plant.

I hope you like above blog. There is no cost associated in sharing the article in your social media. Thanks for Reading !! Happy Learning