Table of Contents

ToggleLive Zero and Dead Zero: Introduction

Analog signal transmission plays an important role in industrial automation and instrumentation. It helps send process variable readings from field instruments to control systems like PLCs (Programmable Logic Controllers) and DCS (Distributed Control Systems).

Among the different types of analog communication, the 4–20 mA current loop is the most widely used standard.

In this system, understanding the difference between Live Zero and Dead Zero is very important. These concepts are often discussed during interviews and while troubleshooting field issues, as they relate to signal interpretation, fault detection, and system reliability.

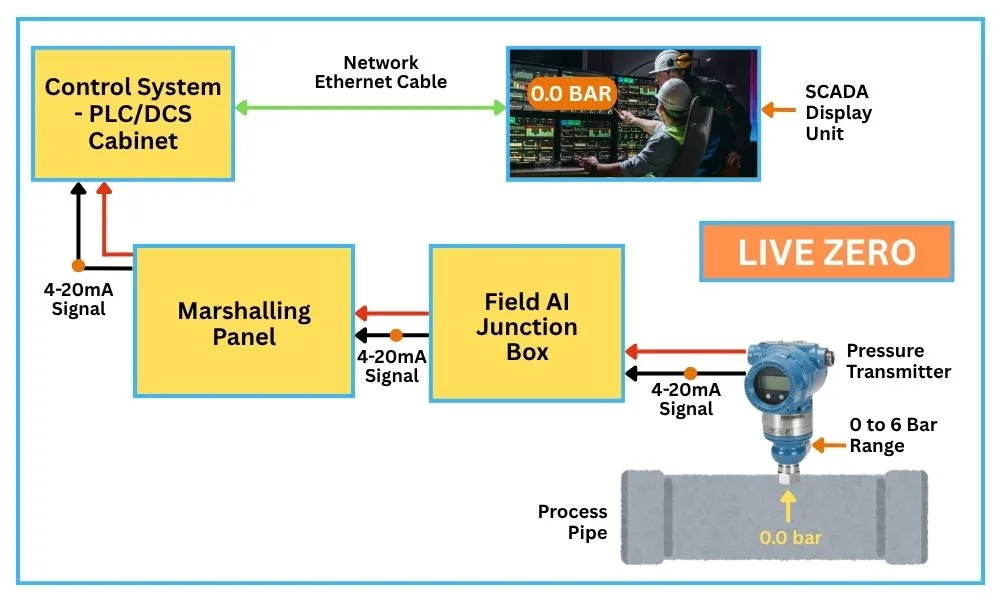

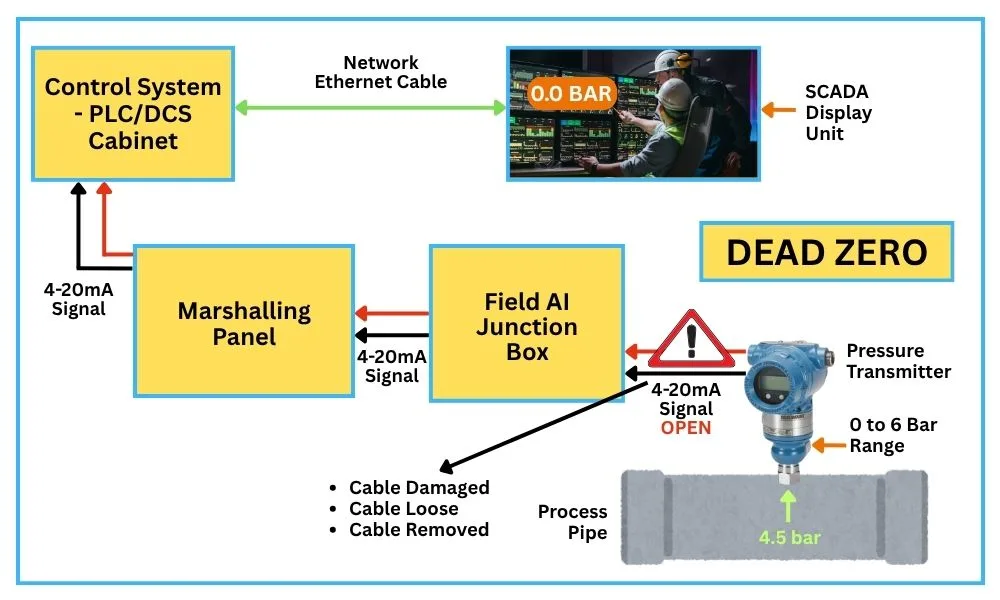

For engineers working with analog loops, the diagrams showing Live Zero and Dead Zero clearly explain this difference making it easier to understand and apply in real-world systems.

4–20 mA Current Loop: Why It is the Standard Signal?

The 4–20 mA current loop is used worldwide because it’s reliable, simple, and can easily tell the difference between a normal signal and a faulty condition.

In this system, the current represents the process variable 4 mA means 0% (the minimum value of the measurement range) and 20 mA means 100% (the maximum value).

Why Not Start at 0 mA?

If 0 mA were used to represent 0% of the process variable (like pressure, temperature, or flow), a broken wire or sensor disconnection would also produce 0 mA. In that case, the control system wouldn’t be able to tell whether the signal was a real zero reading or a signal failure.

That is why the concept of Live Zero and Dead Zero becomes important. It helps engineers clearly identify whether a loop is functioning normally or has a fault.

What is Live Zero In Instrumentation?

In a 4–20 mA current loop, the Live Zero represents the minimum valid current signal, which is 4 mA.

Even though 4 mA corresponds to 0% of the process variable, it still indicates that the loop is working properly and the transmitter is active. That is why it’s called a “Live” Zero, the system is alive and communicating, even at the lowest measurement point.

For example, in a pressure transmitter calibrated for a range of 0 to 6 bar:

- 4 mA = 0 bar (Live Zero)

- 12 mA = 3 bar

- 20 mA = 6 bar

This setup helps ensure that the control system can tell the difference between a true zero reading and a fault condition (like a broken wire or power loss).

In the Live Zero example shown above, the pressure transmitter is sensing 0 bar and is installed on the process line. Even though the pressure is zero, the transmitter is actively sending a 4 mA signal through the loop.

This current travels from the field transmitter to the Field AI Junction Box, then to the Marshalling Panel, and finally reaches the PLC/DCS system. On the SCADA screen in the control room, the pressure is displayed as 0.0 bar, clearly showing that the process is at zero pressure but the signal loop is healthy and alive.

All parts of the signal chain are working properly:

- The field transmitter is powered and operating.

- The signal cable is connected and intact.

- A 4 mA current is flowing, indicating 0 bar pressure but an active communication loop.

This perfectly demonstrates the concept of Live Zero, a zero process value represented by a valid, live signal.

What is Dead Zero In Instrumentation?

Dead Zero occurs when the current in the loop drops to 0 mA, which means there is no signal flowing through the circuit. This indicates a fault or open-loop condition, not an actual process reading.

In other words, Dead Zero does not represent a real process value, it signals that something is wrong in the loop or wiring.

In real-world applications, a reading of 0 mA can happen due to:

- Damaged or broken cables

- Transmitter not powered ON

- Loose or disconnected wiring

- Blown fuse in the circuit

- Faulty terminal connection

So, while Live Zero (4 mA) means “the system is alive and working,” Dead Zero (0 mA) means “the system is dead or disconnected.”

In the Dead Zero example shown above, the actual process pressure is 4.5 bar, which should normally produce around 14 mA of current in the loop. However, due to a problem such as a loose connection, rust, or physical cable damage, the signal wire gets disconnected.

As a result:

- The loop becomes open (no complete electrical path).

- The current drops to 0 mA.

- The controller receives no signal from the transmitter.

- The SCADA screen falsely shows 0.0 bar, even though the real process pressure is 4.5 bar.

This situation clearly demonstrates Dead Zero, a total loss of current that indicates a fault in the loop, not a real process condition.

Why is Live Zero Is Preferred?

In real-world industrial operations, using a Live Zero (4 mA) instead of Dead Zero (0 mA) offers several important advantages:

1) Fault Detection: A drop from 4 mA to 0 mA can be easily detected, triggering alarms for issues like power loss, open circuits, or broken cables.

2) Power Loop Capability: Many 2-wire transmitters are loop-powered, meaning they use the same current for both signal and power. They need a minimum of around 3.5 mA to function, so starting the signal at 4 mA ensures they always stay energized during normal operation.

3) Improved Reliability: With Live Zero, the control system can tell the difference between a true process value (like 0 bar pressure) and a system fault, improving overall accuracy and dependability.

4) Interlocking & Safety: In Safety Instrumented Systems (SIS), a sudden drop to 0 mA is used as a safety trigger to start interlocks or emergency shutdowns, helping protect both personnel and equipment.

What we learn today?

In industrial instrumentation, understanding Live Zero and Dead Zero is very important for ensuring accurate signal transmission and fault detection in analog systems.

The 4–20 mA current loop standard uses 4 mA as Live Zero, representing a valid, working signal even when the process variable is at 0%. This allows the system to confirm that the loop and transmitter are active.

On the other hand, Dead Zero occurs when the current drops to 0 mA, indicating a fault such as a broken wire, disconnected transmitter, or power loss. In short, Live Zero means the system is “alive” and functioning correctly, while Dead Zero signals an issue in the loop that needs troubleshooting.

I hope you like above blog. There is no cost associated in sharing the article in your social media. Thanks for reading!! Happy Learning!!