Table of Contents

ToggleOpen Loop and Closed Loop Control System

In industrial automation and instrumentation, understanding how a control system works is very important.

Two of the most common types are the Open Loop and Closed Loop Control System.

These systems maintain process variables such as pressure, flow, temperature, or level within desired limits.

An open loop system works without feedback, while a closed loop system uses feedback to correct errors automatically.

This article explains how both systems work, their differences, advantages in process industries.

What is a Control System?

A control system is a setup of different devices that work together to control or manage how another system behaves.

it is a system that controls other systems to get a desired result. This is done through something called a control loop, which keeps a process variable like temperature, pressure, flow, or level at the correct value.

Now a days the use of automation is growing fast and it depends on control systems.

Today, control systems are part of almost everything around us.

In daily life, examples of control systems include an air conditioner, refrigerator, automatic iron, and cruise control in cars.

In industries, control systems are used in manufacturing and quality control, power plants, robotics, transportation systems, defense equipment and even space technology.

These systems help make operations faster, safer and more reliable.

Features of a Control System

The most important feature of a control system is that there should be a clear relationship between its input and output.

This means we should be able to describe how the output changes when the input changes.

If this relationship can be expressed using a simple straight-line (linear) equation, the system is called a linear control system.

When the input and output are connected in a more complex way and not following a straight-line relationship then the system is known as a non-linear control system.

In such systems, small changes in input may not always produce proportional changes in output.

What are requirements of a Good Control System?

A good control system should meet certain requirements to perform efficiently and reliably.

Let’s look at the main ones:

1. Accuracy

Accuracy means how close the system’s output is to the desired value. It shows how much error is present when the system is working normally.

Accuracy can be improved by using feedback. In fact, adding an error detector helps the system compare the actual output with the desired output and make corrections automatically.

2. Sensitivity

A control system is affected by changes in temperature, load, or other conditions. Sensitivity shows how much these changes affect the system’s performance.

A good control system should be less sensitive to external disturbances but highly sensitive to input signals.

3. Noise

Noise is any unwanted or disturbing signal that enters the system. It can cause errors or instability in the output.

A good control system should be able to reduce the effect of noise to maintain smooth and accurate operation.

4. Stability

Stability is one of the most important features of a control system. A system is said to be stable if a limited (finite) input produces a limited output, and when the input is zero, the output also becomes zero.

An unstable system may give unpredictable or oscillating outputs, which can be dangerous in industrial applications.

5. Bandwidth

Bandwidth is the range of frequencies over which a control system can operate effectively. A wider bandwidth allows the system to respond to a larger variety of signals.

Therefore, a good control system should have a wide bandwidth for better frequency response.

6. Speed

Speed refers to how quickly a control system can reach its steady-state (stable) output.

A good control system should have high speed and a short transient period, meaning it should settle down quickly after any change in input.

7. Oscillation

Oscillations are small repetitive changes or swings in the system’s output.

A few small oscillations are acceptable, but too many or increasing oscillations indicate instability.

In a good control system, oscillations should be small and consistent.

What are different Types of Control Systems

There are many kinds of control systems, but all of them are designed to control the output of a process. Examples include systems that control position, speed, acceleration, temperature, pressure, voltage, and current.

Let us understand this concept better with a simple example of a room temperature controller.

Example: Room Temperature Control

Imagine you have a room heater. When the heater’s power switch is turned on, the temperature of the room keeps rising. When the desired temperature is reached, you turn off the heater. After some time, as the room cools down, you manually turn on the heater again to warm up the room.

This way, you control the room temperature by turning the heater on and off yourself.

This is an example of a manual control system.

Improved Manual System

Now, if we add a timer switch that automatically turns the heater on and off at regular intervals, the temperature can be maintained more easily.

This is still not fully automatic, but it is a semi-automatic control system.

Automatic Temperature Control

A more advanced system uses a temperature sensor that continuously measures the room’s temperature.

If the temperature drops below the set point, the heater turns on automatically. When the room reaches the desired temperature, the heater turns off.

Here, the system measures the difference (error) between the actual temperature and the desired temperature, and adjusts the heating accordingly.

So, there are two types of control systems

1) Open Loop Control System

2) Closed Loop Control System

In instrumentation, both open loop and closed loop control systems are used to maintain variables like temperature, pressure, or flow at the desired value.

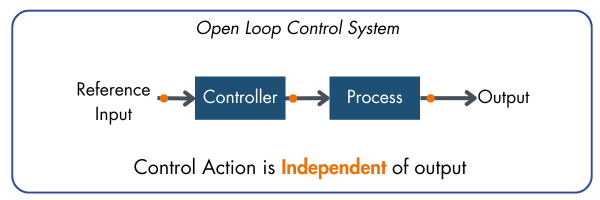

What is Open Loop Control System

A control system in which the control action does not depend on the output is called an Open-Loop Control System. In simple words, the system works only based on the input given to it, without checking whether the desired result has been achieved or not.

A manual control system like switching a room heater on or off by yourself is also an example of an open-loop system.

In an open-loop system, the output does not influence the controller’s action. The system keeps working as per the input command, even if the output changes due to external conditions.

Advantages and Disadvantages of Open Loop

| Advantages | Disadvantages |

|---|---|

| Simple in design and construction | Less accurate due to no feedback |

| Low cost and economical | Unreliable under changing conditions |

| Easy to maintain and operate | Cannot correct errors automatically |

| Generally stable in operation | Performance affected by external disturbances |

| Suitable where output is hard to measure | Output may not match the desired value |

What is a Closed Loop Control System?

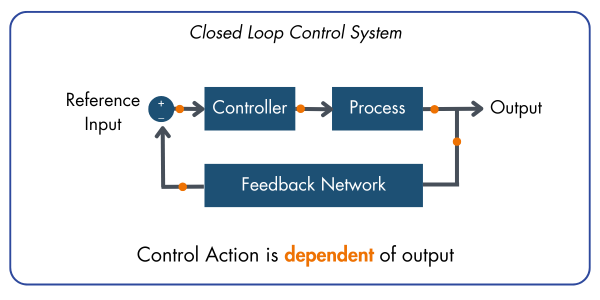

A closed-loop control system is one in which the output affects the input in such a way that the system automatically adjusts itself to achieve the desired result. In simple terms, the system checks its own output and makes corrections whenever needed.

An open-loop system can be turned into a closed-loop system by adding a feedback mechanism. This feedback monitors the output and automatically makes necessary adjustments if there are any changes or disturbances in the process.

Because of this self-correcting ability, a closed-loop control system is also known as an automatic control system.

Advantages and Disadvantages of Closed Loop

| Advantages | Disadvantages |

|---|---|

| High accuracy due to feedback correction | More expensive than open-loop systems |

| Performs well even with non-linear processes | Design is more complex |

| Wide bandwidth and faster response | Requires frequent maintenance |

| Enables full automation | May cause oscillations due to feedback |

| Stability can be adjusted through sensitivity control | Needs skilled supervision |

| Less affected by noise and disturbances | More components increase failure risk |

Comparision of Open Loop vs Closed Loop

| Open-Loop Control System | Closed-Loop Control System |

|---|---|

| Feedback element is absent. | Feedback element is present. |

| No error detector is used. | Includes an error detector to correct output. |

| Generally stable in operation. | May become unstable due to feedback. |

| Simple and easy to construct. | Complex in design and construction. |

| Economical and low cost. | Costly due to additional components. |

| Has a small bandwidth. | Has a large bandwidth. |

| Less accurate, no feedback correction. | Highly accurate due to feedback. |

| Needs less maintenance. | Needs more maintenance. |

| Unreliable, affected by external factors. | Reliable, automatically corrects errors. |

| Examples: Hand dryer, tea maker. | Examples: Servo voltage stabilizer, automatic temperature control system. |

What we learn today?

Both open loop and closed loop control systems are important in automation and instrumentation.

The difference between open loop and closed loop control systems is mainly based on the use of feedback.

While open-loop systems are simple and cost-effective, closed-loop systems offer higher accuracy and self-correction using feedback. Choosing the right type depends on how much control and precision your process requires

I hope you like above blog. There is no cost associated in sharing the article in your social media. Thanks for reading!! Happy Learning!!