Table of Contents

ToggleWhat is a Reed Switch?

A reed switch is a tiny but powerful device that has found its way into countless everyday applications. From door alarms to fluid level detectors, this small component works quietly behind the scenes to make things happen.

What makes it special is that it works purely with magnetism and requires no extra power.

In this article, we will explore the working principle of reed switch in detail, look at how it is used and answer common questions people have about it.

Basic Principle of Reed Switch

At the heart of a reed-switch are two thin metal strips, often called reeds, which are sealed inside a small glass tube. These reeds are coated with a special material that prevents rust and ensures smooth operation.

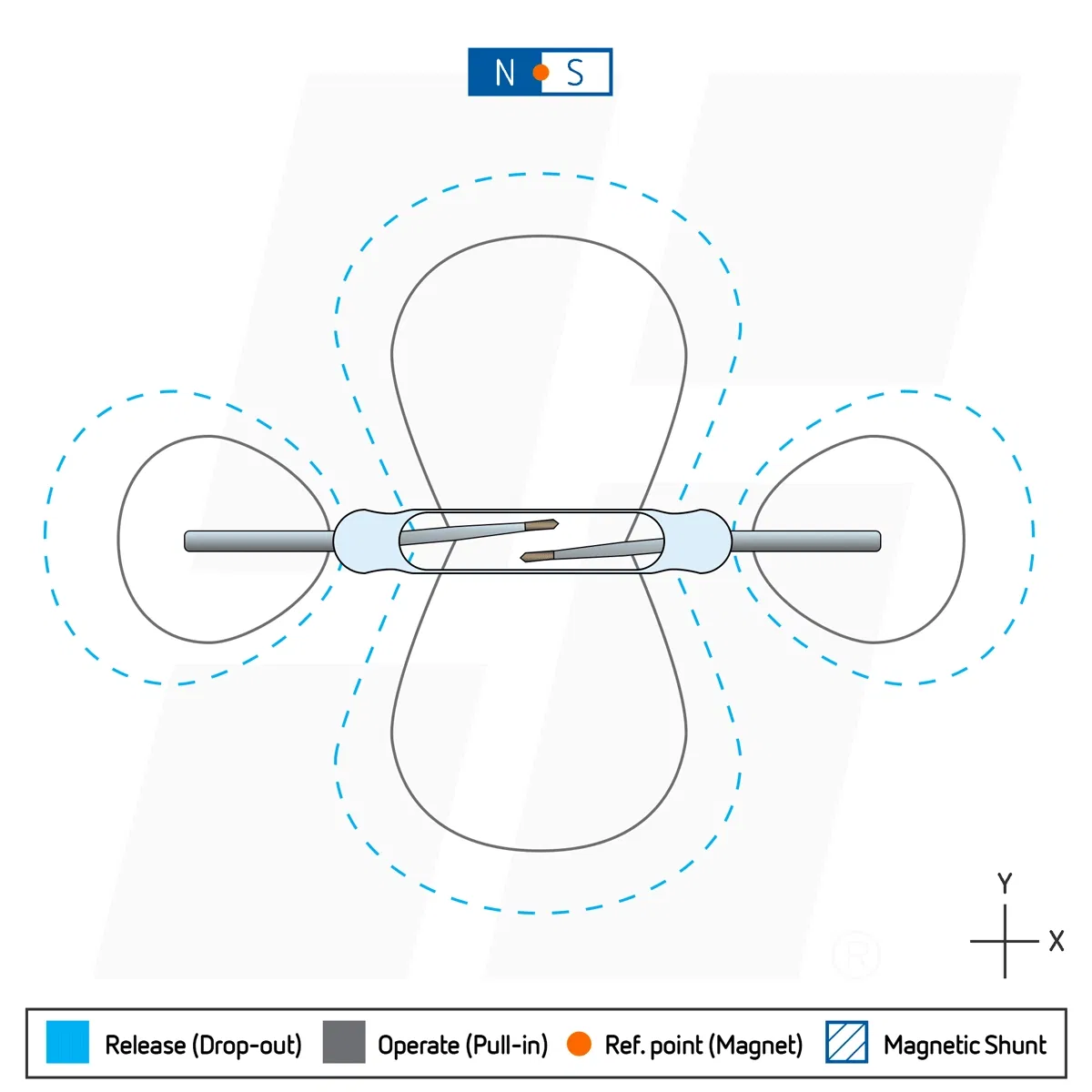

The magic begins when a magnet is brought near. The magnetic field makes the reeds attract each other, and they close to form a contact. This completes the electrical circuit and allows current to pass through.

When the magnet is moved away, the reeds separate again, and the circuit opens. This simple open and close movement is what defines the working principle of a reed switch.

Unlike mechanical switches that depend on pressure or physical movement, a reed switch reacts only to a magnetic field.

Reed Switch in AC and DC Circuits

One of the most common questions is whether a reed switch works with AC or DC. The answer is both. It does not matter if the current is alternating or direct. The reed switch itself does not generate electricity, nor does it need power to operate. It is simply a gate that opens or closes when magnetism acts on it. As long as the voltage and current are within the rated limits, it can handle AC or DC without any trouble.

Where Reed Switches are Used

The versatility of reed-switches has made them popular in many different areas. In home security, they are widely used in door and window alarms. When the door is closed, the magnet keeps the circuit complete. As soon as the door opens and the magnet moves away, the circuit breaks, triggering the alarm.

In industrial applications, reed-switches are used for position sensing, speed measurement, and fluid level detection. For example, in a water tank, a float with a magnet can move up and down. As it passes near the reed switch, it closes the circuit to show whether the tank is full or empty.

Even fitness equipment like treadmills and bicycles use reed switches to count speed and revolutions. Their ability to work without power and in dusty or moist environments makes them an ideal choice for many designs.

Design Features and Construction

Most reed-switches have two wires connected to the metal reeds inside the glass tube. These wires are used to connect the switch to a circuit. While the simplest design has only two wires, some versions come with three wires to provide both normally open and normally closed contacts.

Another interesting point is that reed switches have no polarity. You can connect them in any direction, and they will work the same way. This makes installation simple and flexible.

Some people also wonder if reed switches are filled with water. The answer is no. The inside of the glass tube may contain an inert gas to protect the reeds from corrosion, but never water.

Passive Nature and Lifetime

Reed switches are passive components. This means they do not need power to work. They only respond when a magnetic field is applied. Because there is no friction or mechanical rubbing inside, reed switches can last a very long time. In fact, depending on the design and usage, many reed switches can operate millions of times before showing signs of wear.

This long lifetime and passive nature are two major reasons why reed switches continue to be popular even when electronic alternatives like Hall effect sensors are available.

Alternatives to Reed Switches

Although reed-switches are reliable, some applications require different solutions. Hall effect sensors are one alternative. These sensors also work with magnets but use electronics to detect magnetic fields. They can give more precise readings and sometimes work better in harsh environments.

Another alternative is optical sensors that use light to detect presence or movement. While these technologies are useful, reed-switches remain attractive because they are simple, low cost, and do not need any external power to operate.

Common Questions About Reed Switches

People often have many questions about reed-switches, and here are some of the most important ones explained in detail.

Are reed switches normally open or normally closed?

They can be either. A normally open reed switch stays open until a magnet is near. A normally closed reed switch stays closed until the magnet pulls it apart. Both types are available depending on the need.

How do you test a reed switch?

The easiest way is with a multimeter. Connect the switch to the meter set to measure continuity. Bring a magnet close, and the meter should beep or show a closed circuit. Move the magnet away, and the circuit should open.

Why do reed switches fail?

Although they last long, failures can happen. High current may burn the contacts, mechanical stress may crack the glass tube, or corrosion may occur if the seal is damaged. Using them beyond their rated capacity can also reduce life.

Do reed switches have another name?

Yes, they are often called magnetic switches because of their magnetic working principle.

Advantages

Please see below few advantages:

1) Simple to use: They only need a magnet to work. No extra components are required.

2) Work with both AC and DC: They can safely switch alternating current and direct current.

3) Good switching range: Many can handle up to 200 volts, and some models can carry up to 500 milliamps.

4) No power consumption: They do not use any power on their own and can stay open or closed as long as needed.

5) Reliable in harsh environments: Unlike optical switches, they are not affected by dust or dirt.

6) Can be triggered through materials: A magnet can activate the switch even through non-magnetic barriers like plastic, wood, or paper.

7) Long lifetime: With no moving mechanical parts rubbing against each other, reed switches can last for millions of operations.

Disadvantages

They also have few disadvantages as below

1) Need an external magnet: They cannot work alone and require a separate magnet placed close by.

2) Limited sensing distance: If the magnet is more than a few millimeters away, the switch may not activate.

3) Size limitations: They cannot be miniaturized as much as tiny surface mount chips.

4) Fragile design: The glass capsule around the reeds is delicate and can break if handled roughly.

5) Contact arcing: Small sparks can form between the reeds when switching higher voltages or currents.

6) Restricted sensing ability: They only respond to magnetic or ferrous materials and cannot detect non-metallic objects.

7) Magnetic interference: They may activate accidentally if exposed to strong nearby magnetic fields.

8) Debouncing needed: When used with logic circuits or controllers, additional steps are required to avoid false signals caused by contact bounce.

Web Stories

I hope you like above blog. There is no cost associated in sharing the article in your social media. Thanks for reading!! Happy Learning!!