Table of Contents

ToggleWhat is an Annubar flow meter (averaging Pitot)

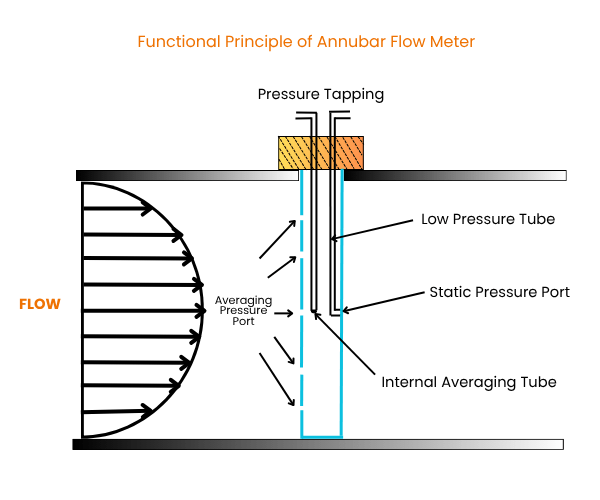

Annubar Flow Meter is nothing but as a smart bar (a probe) that you insert into the pipe. It has many small pressure taps (holes) along its face upstream and a corresponding set (or a chamber) downstream.

These taps “average” the pressure profile rather than relying on just one point. The difference between “high side” (impact + static) and “low side” (static, suction) is your differential pressure (ΔP). From that ΔP, you infer flow rate using the relevant equation.

Because real flow inside pipes is never perfectly uniform (boundary layers, turbulence, bends, etc.), using multiple taps helps reduce error compared to a single-point measurement. Many of the best explanations online call it an “averaging Pitot” or “averaging bar.”

“Annubar” is a brand name (Emerson / Rosemount) but over time the term is used generally for that style of device.

How Annubar Flow Meter works?

Here is what actually happens inside the pipe when you mount an Annubar:

Insertion and obstruction

You insert the bar so that it spans (or partially spans) across the pipe cross-section. It is not a full blockage, but it disturbs the flow slightly. That disturbance causes a pressure difference between upstream side and downstream side.

Tapping pressures (high and low side)

1) Upstream side: Several ports facing the flow pick up total pressure (static + dynamic). These ports feed into a common chamber (or manifold) that gives you an averaged “high side” pressure reading.

2) Downstream: There is a downstream port or chamber that senses mostly static (lower) pressure, or what you’d call the “suction” side.

Forming ΔP (differential pressure)

The differential Pressure = High Pressure – Low Pressure

That difference is (theoretically) proportional to (velocity)2, by Bernoulli’s principle. From that, with known pipe cross-sectional area etc., you calculate volumetric flow.

Conversion to flow

A DP transmitter which is an secondary device reads the ΔP. Then in your flow computer, DCS or PLC logic you apply calibration constants, K-factors, and square-root extraction (or a lookup) to convert that ΔP into flow rate.

So Annubar creates ΔP → DP transmitter measures → we convert ΔP → FLOW.

Basic Formula Behind it

The Basic Formula is as below:

where:

Q = Flow Rate

K = Annubar Flow Coefficient

DP = Differential Pressure

The Annubar creates a pressure difference (DP) by partially blocking the pipe. When the fluid hits the front of the Annubar, its speed slows down and comes to a stop at that point, which builds up the high pressure.

Please see below functional diagram of Annubar Flow Meter.

Advantages of using Annubar Flow Meter

1) Low pressure drop / minimal blockage

Because it’s not a full obstruction, permanent pressure loss is pretty low, better than many orifice or flanged flow elements.

2) Better represent average flow

Using multiple taps helps mitigate nonidealities in velocity profile, so you get a more reliable average reading compared to a single point Pitot.

3) Flexible installation

You don’t always need long flanged spool sections or special piping, many Annubars flow meters are designed for insertion or “through the wall” style installations using pack-offs or small apertures.

4) Scalable to large pipes

For very large pipe diameters, the forces on a primary element (if fully spanning) can be large. But many Annubar flow meter designs support ends or supports so the bar is held securely, making them robust even in large diameter lines.

Disadvantages of using Annubar Flow Meter

1) Clogging / fouling (dirty fluids)

If your fluid carries particulates, deposits, or solids, the small taps can block. Cleaning sometimes requires removing the bar (mechanical cleaning) or high-pressure purge.

2) Viscosity limitations

If fluid viscosity is high (say approaching or exceeding ~50 cP), the assumption of ideal Bernoulli behavior starts to break down; the measurement error may increase.

3) Sensitivity (low DP signals)

Because the ΔP is often quite small (especially at low flow), instrumentation noise, zero drift, transmitter resolution become more critical.

4) Straight-run requirements

The upstream and downstream piping must be fairly “clean” (no disturbances) over certain lengths, otherwise the flow profile is distorted and your measurement becomes inaccurate. For example:

4.1 => For a pipe bend: allow ~23 diameters upstream and 4 downstream.

4.2 =>For a valve upstream: maybe ~30 upstream diameters, 4 downstream.

5) Single instrument point / single sensor

Even though Annubar flow meter samples multiple taps, it is still one primary that you rely on. If it fails, your entire flow measurement is lost. Some people ask whether you can put multiple DP transmitters on one Annubar flow meter to improve redundancy, but that has tradeoffs, as if the sensor itself fails, all are lost.

Checklist during installation & commissioning of Annubar Flow Meter

Here is a “checklist” you should have in your pocket when going in the field. Use this, and we reduce surprises:

1) Confirm pipe sizing, fluid properties, working range

We must ensure that the Annubar we pick is sized for the expected flow range, fluid density, temperature, pressure, etc. Also check viscosity, particulate load, corrosivity.

2) Proper orientation and insertion depth

The bar (or “averaging section”) should ideally span the full cross-section or be positioned so that the multiple taps sample the velocity profile well. It must be centered (or as manufacturer prescribes) and not too close to walls.

3) Straight run lengths

Make sure upstream and downstream sections are adequate and free from disturbances (bends, valves, reducers) according to the recommended rules. If you can not get full length, sometimes you may consider straighteners or vanes upstream.

4) Impulse/connection lines / tubing

Use matched tubing, minimal slope, and avoid loops (air pocket). Make sure you purge before commissioning and ensure no leaks. Keep impulse lines short & consistent.

5) Zeroing / calibration

After you mount and connect the DP transmitter, you must zero the system in no-flow condition (if possible). Also check span calibration. Use calibration gas if needed.

6) Signal filtering / dampening

Because ΔP might fluctuate, consider whether filtering or signal smoothing is required in transmitter or DCS side. But don’t over-filter and lose fidelity.

7) Leak tightness

Check all joints, fittings, impulse port connections for leaks (especially on high side). Leaks skew ΔP dramatically.

8) Vibration / support

The bar should be mechanically stable; avoid vibration or movement in the pipe that can shift it. Use supports, proper mounting.

9) Redundancy & diagnostics

If possible, configure diagnostics (e.g. check ΔP differential, alarms on drift, diagnostics in transmitter). Always plan for a fallback or bypass.

Operation & maintenance of Annubar Flow Meter

Once you have commissioned it, the Annubar still needs attention. Here’s what I’d keep in mind and what I’d tell you to monitor:

1) Periodic inspection & cleaning

If process fluid has sediments, scale or fouling. Sometimes you might need to shut off flow, remove the bar, clean taps. Or in some systems, do a purge (if a purge port exists).

2) Zero drift & re-zeroing

Periodically check zero offset (especially when process is shut). Drift can occur due to temperature, stress, transmitter aging.

3) Check for tap blockages

If reading seems off or erratic, suspect one or more ports are blocked. One port blocked is especially harmful because averaging is skewed.

4) Check impulse lines

Over time, moisture, condensation, or debris can accumulate. Also watch out for leaks, corrosion.

5) Monitor transmitter health

Watch for transmitters going out of range, alarms, unexpected ΔP behavior.

6) Record trends & compare

Use redundancy (if you have alternate flow measurement) occasionally to compare. If readings diverge, dig in.

7) Replace before catastrophic failure

Bars may eventually corrode or weaken over time; replace before cracks or major damage develop.

I hope you like above blog. There is no cost associated in sharing the article in your social media. Thanks for reading!! Happy Learning!!