When it comes to industrial pressure measurement, accuracy is everything.

Whether we are checking a simple pressure gauge in a workshop or calibrating high end transmitters in a laboratory, the need for a reliable reference is always there. Among all the available methods of pressure calibration, the dead weight pressure tester stands out as the primary standard. It has been trusted for decades because it is based on the most fundamental principle of physics: pressure is equal to force divided by area.

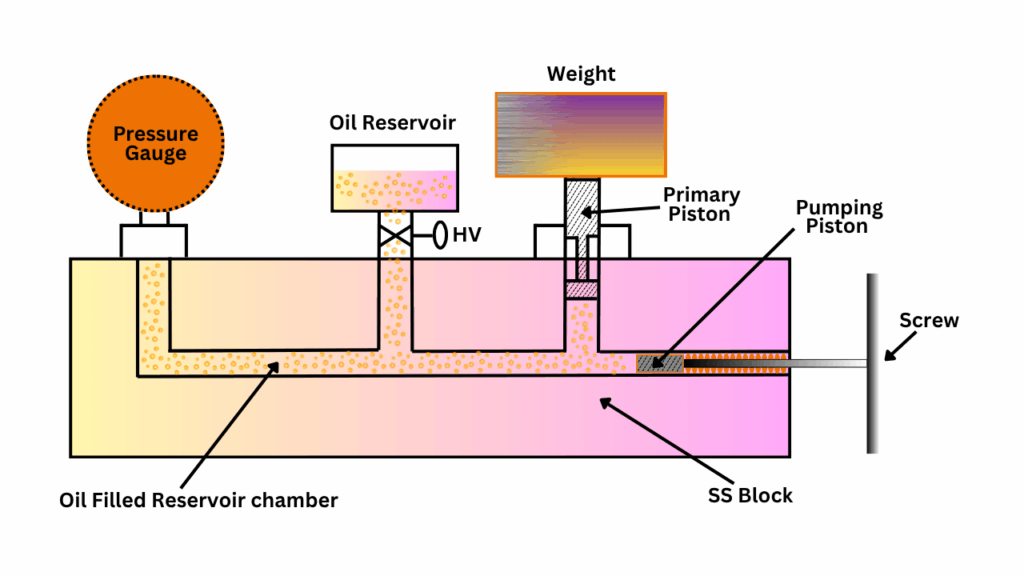

A dead weight pressure tester, also called as pressure balance, generates pressure using known weights placed on a precisely machined piston. The downward force of these weights, combined with gravity, creates an upward pressure in the fluid beneath the piston. Because the area of the piston and the value of gravity are measurable, the pressure generated can be calculated very accurately. This makes the device a cornerstone in pressure calibration laboratories worldwide.

Table of Contents

ToggleHow the Dead Weight Pressure Tester Works?

Let us understand what a dead weight tester is.

In simple terms, it is a device that uses known weights to check if pressure gauges are showing correct readings. The main parts of this tester are a fluid system, a connection port, and a piston with weights on top. The pressure it generates is worked out using a basic formula

p = F / A

Where,

p: Reference Pressure (Pa)

F: Force applied to the Piston (N)

A: Area PCU (m2)

How is Pressure Gauge Calibrated Using Dead Weight Tester?

To calibrate a pressure gauge using a dead weight tester, you need to follow a series of steps carefully to make sure the calibration is accurate. The process is explained below.

Step 1: Setting Up the Equipment

Begin by placing the dead weight tester on a flat, stable, and level surface. A shaky or uneven bench can affect the results. Once the tester is secure, connect the pressure gauge you want to calibrate to the test port. This makes sure the gauge is part of the system and ready for calibration.

Step 2: Checking the Zero Reading

Before applying any pressure, look at the gauge to confirm that it reads zero. If it doesn’t, adjust it until the pointer is set exactly at zero. This step is important because leaving a zero error unchecked can lead to incorrect calibration.

Step 3: Adding the Reference Weight

Now the actual calibration begins. Select the appropriate reference weight based on the pressure you want to apply. Place this weight carefully on the vertical piston of the dead weight tester. These weights are what generate the known reference pressure.

Step 4: Operating the Piston

The tester is designed with a horizontal piston that has a handle attached to it. Slowly turn the handle to build pressure. Keep doing this until the oil inside supports the vertical piston and the weight placed on it. At this point, gently rotate the vertical piston so it floats freely. A free-floating piston means the correct reference pressure has been established.

Step 5: Noting Down the Readings

Allow the system a little time to stabilize. Once it is steady, record the reading shown on the pressure gauge and compare it with the known value from the applied weight. This comparison tells you whether the gauge is showing accurate results.

Step 6: Completing the Calibration

Repeat the process of adding weights, operating the piston, and recording the readings until the gauge reaches its maximum pressure range. After reaching the top value, gradually remove the weights one by one, watching the gauge as it comes back down to zero. If the gauge shows consistent readings within the acceptable accuracy limits throughout the cycle, then the calibration has been successful.

Dead weight testers are versatile and reliable tools. They can be used to calibrate a wide range of instruments, including industrial pressure gauges and pressure transmitters. Because of their accuracy and dependability, they are still widely used in industries where precise pressure measurement is essential.

For a gas-operated pressure balance (Dead Weight Pressure Tester) working in gauge mode, the pressure is defined by the basic relationship:

In this case, the force is created by the weights placed on the piston. That force is simply the product of mass and the acceleration due to gravity:

So, the pressure applied to the system is determined by dividing this force by the effective area of the piston.

∑ represents summation.

Pe is the gauge pressure measured at the bottom of the piston.

mi refers to the mass of each individual weight placed on the piston, including all floating parts.

g is the local acceleration due to gravity.

ρa is the density of air.

ρmi is the density of each weight.

Ap is the effective area of the piston–cylinder assembly at the reference temperature tr.

αp is the linear thermal expansion coefficient of the piston.

αc is the linear thermal expansion coefficient of the cylinder.

t is the actual temperature of the piston cylinder assembly during operation.

tr is the reference temperature of the piston cylinder assembly, usually taken as 20 °C

For a liquid operated pressure balance (Dead Weight Pressure Tester), the same type of expression can be used. However, in this case, the total force is not only from gravity but also includes the additional force created by the surface tension of the liquid.

Where:

σ is the surface tension of the liquid.

c is the circumference of the piston, or its extension, at the level where it comes out of the oil.

Types of Dead Weight Testers

There are mainly two common types of dead weight testers => hydraulic and pneumatic.

The hydraulic dead weight tester uses fluids like oil or water as the medium. It is generally employed for higher pressure ranges and provides stable performance. However, care must be taken to keep the oil clean, and there is always a risk of contamination if used in sensitive environments.

The pneumatic dead weight tester uses air or inert gases like nitrogen. These are preferred for lower to medium pressure ranges and in applications where cleanliness is critical, such as in laboratories or clean manufacturing areas. Pneumatic testers are also lighter to operate since no heavy oil pumping is required.

Specialized designs also exist for vacuum dead weight testers, which are used to calibrate instruments working at negative pressures relative to the atmosphere.

Accuracy and Why It Matters

Dead weight testers are renowned for their accuracy. Depending on the model and manufacturer, their accuracy can range from 0.005% to 0.1% of the reading, which is far better than most other calibration methods. This level of accuracy is the reason they are still considered the “gold standard” in pressure calibration. National laboratories and accredited calibration centers use dead weight testers to establish traceability to international units.

Advantages and Limitations Dead Weight Pressure Tester

Advantages:

- Very reliable and highly accurate.

- Based on primary physical quantities (mass, length, and time), so no frequent recalibration is needed.

- Long service life if properly maintained.

- Can be used across a wide pressure range.

Limitations:

- Bulky and not as portable as modern electronic calibrators.

- Require careful handling and operator training.

- Setup takes more time compared to digital devices.

- Corrections and calculations can seem complex for beginners.

- Not ideal for field use where speed and convenience are more important—digital calibrators or comparators are better in such cases.

Applications in Industry

Dead weight testers are widely used wherever accuracy in pressure measurement is important. They are common in calibration laboratories where traceability to national standards is required. Industries like oil and gas, power generation, pharmaceuticals, and manufacturing use them to ensure that their pressure instruments are trustworthy. Even in research labs and test facilities, dead weight testers continue to play a vital role as a reference device.

I hope you like above blog. There is no cost associated in sharing the article in your social media. Thanks for reading!! Happy Learning!!