Table of Contents

ToggleArtificial Intelligence – AI

Machine Learning – ML

In modern plant whether it is oil & gas, water treatment, power generation, or pharmaceuticals, you will notice one thing: Data is everywhere.

Every pipeline, vessel, or machine is equipped with instruments measuring flow, pressure, temperature, level, or chemical composition. These measurements are the lifeblood of industrial processes.

A single refinery, for example, may have tens of thousands of sensors producing real-time data. Handling this information with traditional methods is no longer enough.

This is where Artificial Intelligence (AI) and Machine Learning (ML) come into play. Instead of just collecting data, industries are now asking:

- Can this data predict failures before they happen?

- Can we optimize operations automatically?

- Can machines learn patterns and improve accuracy over time?

The answer is a yes and AI + ML together are making it possible.

What Do We Mean by AI & ML in Instrumentation?

Let’s simplify these terms:

- Artificial Intelligence (AI): The broader concept of machines being able to “think” or make decisions like humans. In instrumentation, this could mean systems that decide when to recalibrate a sensor without human input.

- Machine Learning (ML): A subset of AI where machines learn from past data. Instead of being explicitly programmed, they find patterns. In instrumentation, this could be detecting that a pump always fails after showing a particular vibration signature.

In short:

Why Does Instrumentation Need AI/ML?

Traditional instrumentation systems are rule-based.

They follow pre-programmed logic: if a temperature goes above 90°C, trigger an alarm. While this works, it has limitations:

Too many alarms: Operators get flooded with signals, many of which are false alarms.

Unpredictable failures: Traditional systems can’t always warn you before something breaks.

Data underutilization: 80–90% of sensor data is often ignored because humans can’t process it all.

Maintenance inefficiency: Instruments are often calibrated or replaced on fixed schedules, not based on real condition.

With AI/ML, we move from reactive to predictive and prescriptive instrumentation.

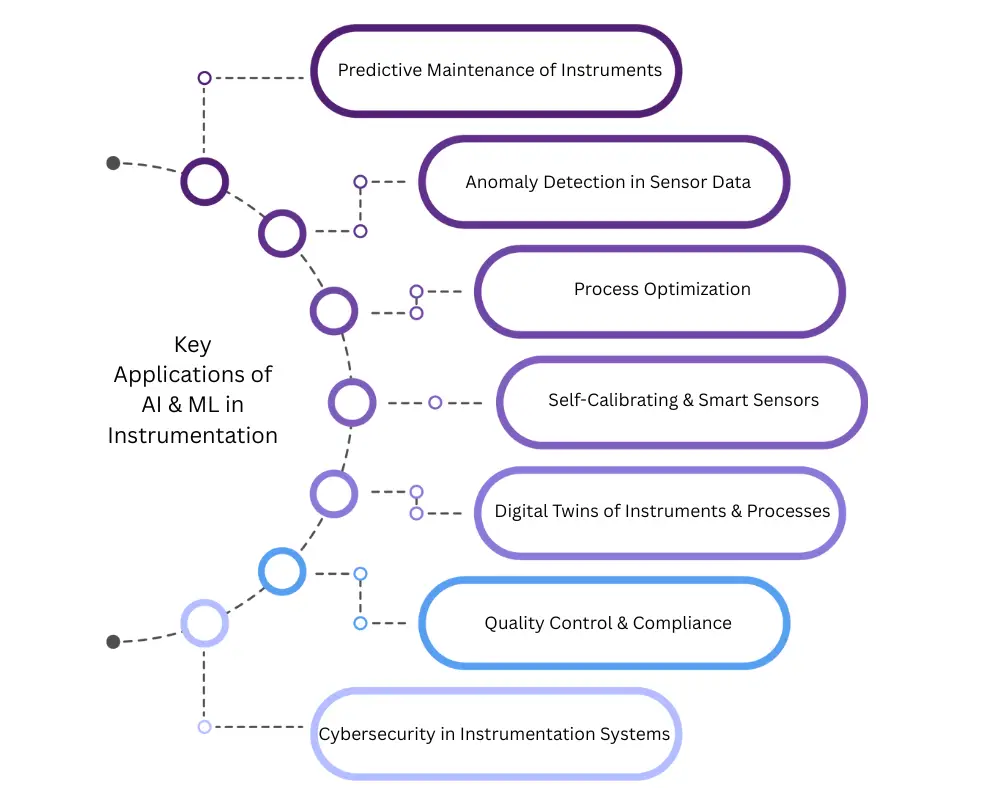

Key Applications of AI & ML in Instrumentation

1. Predictive Maintenance of Instruments

Imagine a flowmeter in a chemical plant. Traditionally, it is calibrated every six months. But sometimes, it drifts earlier or sometimes it remains accurate much longer.

- With ML: Historical calibration data, process conditions, and drift patterns are fed into algorithms. The system predicts the exact time the meter will go out of tolerance.

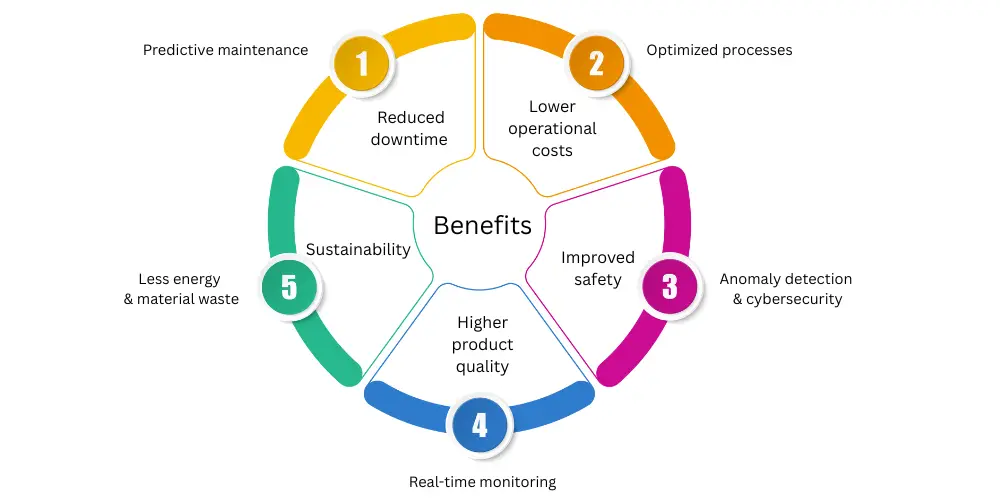

- Benefit: Reduced downtime, fewer unnecessary calibrations, and cost savings.

Example: Vibration sensors on rotating equipment can feed ML models that predict bearing failures weeks in advance.

2. Anomaly Detection in Sensor Data

Sensors sometimes give faulty readings due to dust, corrosion, or electrical noise. If unnoticed, these errors can mislead operators.

- With AI: Artificial Intelligence Algorithms continuously compare a sensor’s data against “normal” patterns. If a pressure sensor suddenly reports unrealistic spikes while other process conditions are stable, the system flags it as an anomaly.

- Benefit: Prevents wrong decisions and unsafe conditions.

This is already being applied in oil & gas pipelines, where AI monitors pressure/flow data to detect leaks or blockages early.

3. Process Optimization

Instruments do not just measure. They guide control systems. AI can analyze massive amounts of data to fine-tune operations.

- Example: A steam boiler has sensors for temperature, pressure, and flow. Artificial Intelligence models can optimize fuel-air mixture, reducing energy consumption while maintaining safety.

- Result: Lower costs, higher efficiency, reduced emissions.

Think of it like a navigation app: instead of just showing where you are, it constantly finds the best route based on traffic (process conditions).

4. Self-Calibrating & Smart Sensors

Calibration is a big headache in instrumentation. AI is enabling self-calibrating instruments that adjust automatically.

How it works:

- Sensor collects data.

- AI compares it with reference models.

- If drift is detected, it applies correction without human intervention.

This is especially useful in remote or hazardous locations where frequent manual calibration is impractical (like offshore rigs).

5. Digital Twins of Instruments & Processes

A digital twin is a virtual copy of a physical system. AI/ML models help build these twins using real-time instrument data.

- Use case: A refinery can have a digital twin of its distillation column. By feeding sensor data (temperature, pressure, flow), AI predicts how the column will behave under different conditions without touching the real equipment.

- Benefit: Safer experiments, faster troubleshooting, and better planning.

6. Quality Control & Compliance

In industries like pharmaceuticals or food processing, instrumentation ensures strict quality compliance.

- With AI: Sensor data is analyzed in real time to detect deviations early. For example, if pH drifts slightly outside safe limits, Artificial Intelligence can stop production before an entire batch is wasted.

- Impact: Reduced waste, compliance with FDA/ISO standards, and safer products.

7. Cybersecurity in Instrumentation Systems

As instruments connect to IoT and cloud systems, they become potential targets for cyberattacks.

AI Role:

- Detect unusual network traffic from smart instruments.

- Identify fake sensor signals injected by hackers.

- Isolate compromised devices.

AI acts like a security guard. He is continuously monitoring the health and authenticity of sensor networks.

Examples

Oil & Gas:

- BP uses AI models to analyze vibration/flow data from offshore platforms, reducing unplanned downtime.

- Shell applies predictive analytics to pipeline monitoring, catching leaks early.

Water Treatment:

- AI-powered turbidity and chlorine sensors optimize chemical dosing, saving costs and ensuring safe water.

Pharmaceutical Industry:

- Machine learning ensures batch quality by monitoring temperature, pressure, and mixing conditions in real time.

Smart Manufacturing:

- AI-driven flow and pressure monitoring improve energy efficiency in compressed air systems—often a hidden cost.

Challenges in Applying AI/ML to Instrumentation

Of course, it is not so easy. There are hurdles:

Data Quality: AI is only as good as the data. If instruments give poor or inconsistent data, predictions fail.

Integration Issues: Many plants still use legacy instruments with no connectivity.

Cybersecurity Risks: More connectivity means more attack surfaces.

Skill Gap: Engineers may not be trained in data science, making adoption slow.

High Initial Cost: AI/ML integration requires investment in infrastructure and expertise.

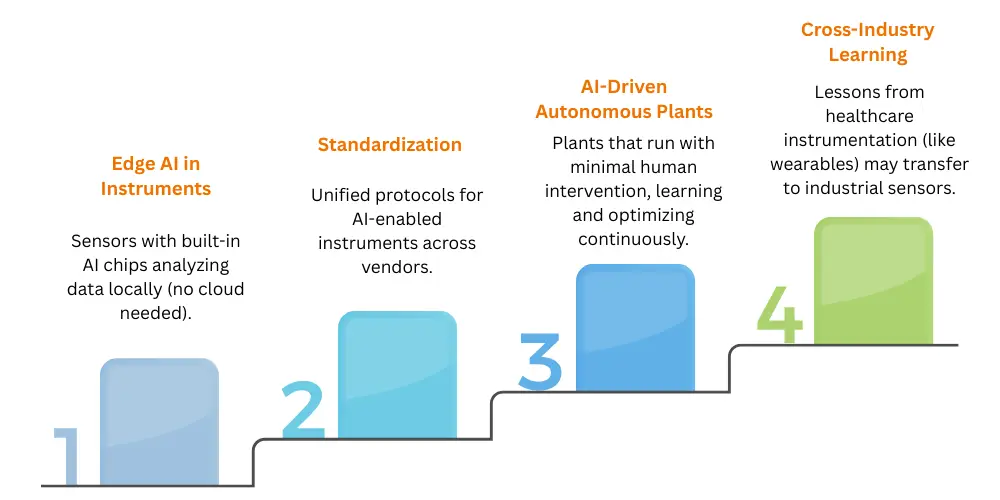

Future Outlook

The role of AI in instrumentation will only grow. Here is what we can expect in the next 5–10 years:

Final Takeaway

Instrumentation has always been about measurement but now, with AI and Machine Learning, it is about intelligence and foresight.

Artificial Intelligence helps us use sensor data better, from spotting equipment problems early to running processes more smoothly.

It makes work safer, cleaner, and more efficient.

For engineers and technicians, there is nothing to worry about. Just like digital controllers replaced old pneumatic systems years ago, AI will soon be a normal part of every instrumentation system.

The message is clear:

The future of instrumentation is not just about measuring—it is about learning, predicting, and improving.

I hope you like above blog. There is no cost associated in sharing the article in your social media. Thanks for reading!! Happy Learning!!

1 Comment