RTDs, or Resistance Temperature Detectors, are sensors used to measure temperature.

Their are two main types: wire-wound & thin-film.

These sensors have a thin layer of metal built on a ceramic base, which makes them reliable and more accurate than other common sensors like thermocouples or thermistors.

As we know that RTDs are used in high temperature places, they need to be made from strong and stable materials. That is the reason metals like copper, nickel, & platinum are commonly used.

Out of these, platinum is the most popular especially in industries because it gives very accurate readings and lasts a long time.

So, why is platinum the top choice for RTD sensors?

That is exactly what we are going to learn in this article.

Table of Contents

ToggleAccuracy and Linearity

Let us start with what matters most in any measurement: accuracy.

Platinum has a naturally linear and stable relationship between temperature and electrical resistance. That means as temperature changes, its resistance increases in a predictable and repeatable way.

Most platinum RTDs, like the common Pt100, have a tolerance as low as ±0.1°C much more accurate than thermocouples or thermistors, especially in the -200°C to 600°C range.

Why it matters: In industries like pharmaceuticals or semiconductor manufacturing, even a 1°C deviation can lead to failed batches or product rejection. Using platinum ensures the system maintains tight control with confidence.

Wide Operating Temperature Range

Another reason platinum is preferred is its excellent performance across a very wide temperature range.

Typical platinum RTDs can measure from -200°C to +600°C, and some specialized designs can go even higher.

This makes platinum suitable for:

- High-temperature ovens, kilns, and reactors

- Low-temperature cryogenic applications

- Everything in between

Why it matters: You do not need to switch sensor types for different process ranges. Platinum RTDs provide a single, dependable solution for nearly any temperature zone.

Long Term Stability & Repeatability

In industrial environments, the last thing you want is sensor drift. Imagine recalibrating hundreds of sensors every few months just because they lose accuracy over time.

Platinum RTDs are known for their ability to hold calibration for years, even in demanding conditions.

Unlike thermocouples, which tend to drift due to oxidation or contamination, platinum’s structure and resistance remain stable.

Why it matters: Once installed and calibrated, platinum RTDs can run reliably for years with minimal maintenance saving both time and operational cost.

Chemical & Environmental Resistance

Platinum is a noble metal, meaning it resists corrosion and chemical attack. It doesn’t oxidize or degrade easily, even when exposed to moisture, gases, acids, or other harsh elements. This resistance makes platinum ideal for use in rugged, corrosive environments.

Whether it is a marine site, a chemical plant, or an outdoor process setup, platinum’s inert nature ensures reliability.

Why it matters: In industries like oil & gas or wastewater treatment, sensors are constantly exposed to chemicals and environmental challenges. Platinum RTDs are well suited to survive and perform consistently.

Excellent Mechanical Workability

Platinum is easy to form into fine wires or thin films, which makes it suitable for both traditional wire wound and thin film RTDs.

This flexibility in construction helps manufacturers offer a wide range of designs from ultra compact sensors for tight spaces to high end wire wound RTDs for laboratory use.

In automation and control systems, where form factor and space often matter, platinum’s versatility gives designers freedom.

Why it matters: Platinum RTDs can be shaped to suit various applications without compromising accuracy or durability.

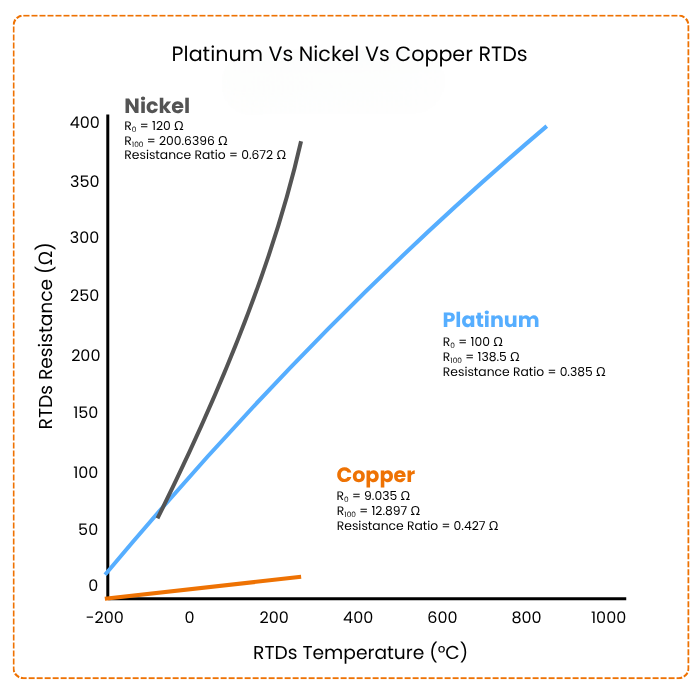

RTD resistance ratio

The term “resistance ratio” refers to the average rate at which the resistance of an RTD increases as the temperature rises from 0°C to 100°C. It shows how much the resistance changes with temperature over this range. The formula for calculating resistance ratio is:

(R100-R0) / R0

Where:

R100 = RTD Resistance at 100°C.

R0 = RTD Resistance at 0°C.

Platinum RTDs used in industrial settings usually follow the IEC 60751 standard. According to this standard, the resistance of the RTD increases from 100 Ω at 0°C to 138.5 Ω at 100°C, giving a resistance ratio of 0.385 Ω/°C.

In most industrial applications, these RTDs are placed inside stainless steel sheaths to protect them from harsh environments.

Pt100 vs Pt1000 – What is the Difference?

You often hear about Pt100 and Pt1000 RTDs.

- Pt100 means the sensor has 100 ohms resistance at 0°C

- Pt1000 means it has 1000 ohms at 0°C

Both have similar characteristics, but Pt1000 sensors generate stronger signals, which is helpful in long cable runs or 2-wire installations where signal loss is a concern.

| Feature | Pt100 | Pt1000 |

|---|---|---|

| Resistance | 100Ω @ 0°C | 1000Ω @ 0°C |

| Signal strength | Lower | Higher |

| Noise immunity | Needs 3/4-wire | Works with 2-wire |

| Cost | Slightly lower | Slightly higher |

Where Are Platinum RTDs Used?

Platinum RTDs are common in nearly every industry where accurate and stable temperature monitoring is needed.

- Oil & Gas – temperature monitoring of lines and separators

- Industrial automation – process control, tank monitoring, motor protection

- Pharmaceuticals – sterilization, lab instrumentation

- Cold chain logistics – cryogenic temperature monitoring

- Power generation – turbine and boiler temperature control

- Automotive – engine management systems, exhaust gas monitoring

- Food and beverage – cooking, chilling, fermentation

Are There Any Drawbacks?

The only major drawback of platinum is its cost.

Platinum is a precious metal and RTDs made from it tend to be more expensive than thermocouples or copper based RTDs.

But here is the tradeoff: You get better accuracy, durability, and long term savings on calibration & maintenance.

Choice is yours !

If you are designing or maintaining a system that demands precision, consider platinum RTDs, then they are not just a sensor, they are a long term partner in performance.

I hope you like above blog. There is no cost associated in sharing the article in your social media. Thanks for reading!! Happy Learning!!