Table of Contents

TogglePressure Tappings in Orifice Plate: Introduction

When we talk about differential pressure flow measurement, the orifice plate is often the first device that comes to mind. It is simple, reliable, and widely used across industries like oil & gas, water treatment, power plants, and chemical processing.

But here is something many beginners ignore.

The accuracy of an orifice plate system does not depend only on the plate itself. It heavily depends on how and where the pressure is tapped from the pipe.

This is where Pressure Tappings in Orifice Plate become extremely important.

In this article, we will clearly understand:

What pressure tappings are

Why their location matters

Types of pressure taps used with orifice plates

When to use which tapping type

Practical selection guidance

Let us begin from the basics.

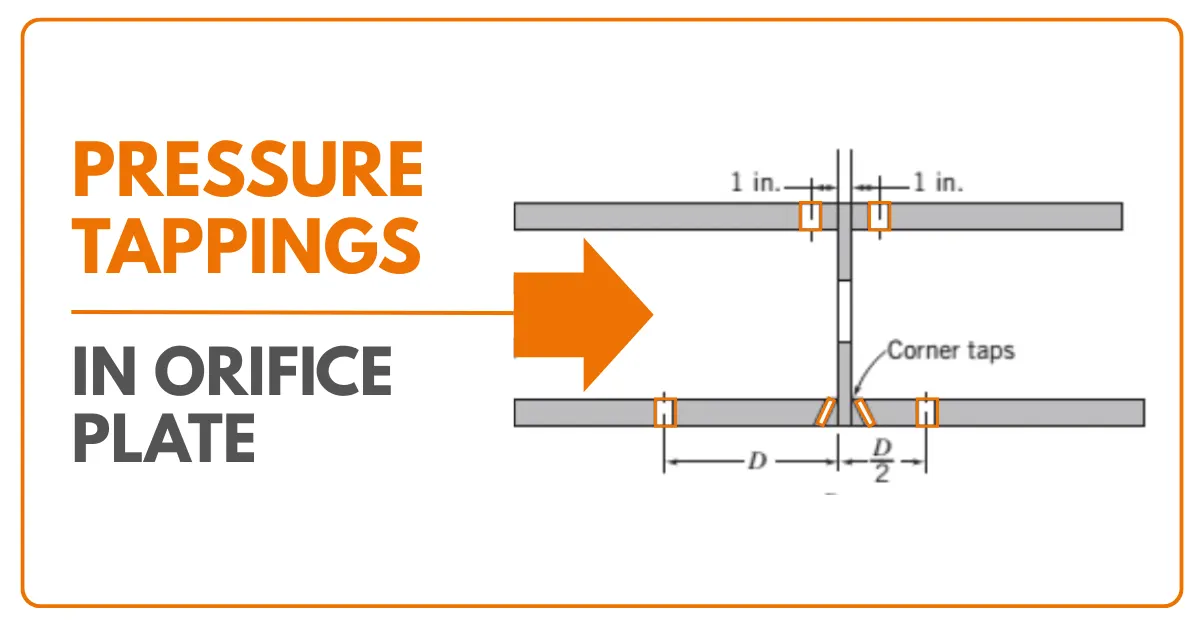

What Are Pressure Tappings in Orifice Plate?

An orifice plate works on Bernoulli’s principle.

When fluid passes through the restriction (orifice), velocity increases and pressure decreases. By measuring the pressure difference between two points (upstream and downstream), we can calculate the flow rate.

But how do we measure this pressure difference?

We drill small holes in the pipe or flange and connect impulse lines to a differential pressure transmitter. These holes are called pressure tappings.

So in simple words:

Pressure tappings are small openings in the pipe that allow us to measure high and low pressure across the orifice plate.

Their position determines:

The magnitude of differential pressure

Measurement accuracy

Calibration constant

Compliance with standards like ISO 5167 and ASME

Even a small change in tapping location can change the discharge coefficient and final flow reading.

That is why understanding pressure tappings in orifice plate is critical.

Why Tapping Location Matters So Much?

After fluid passes through an orifice plate:

Pressure drops suddenly at the restriction.

The lowest pressure occurs slightly downstream at the vena contracta.

Pressure gradually recovers further downstream.

Now imagine this.

If you take the downstream pressure reading at the wrong point, you will not measure the correct differential pressure. That directly affects flow calculation.

Different industries and standards allow different tapping locations. Each has its own advantages and limitations.

Let us now explore each type in detail.

Types of Pressure Tappings in Orifice Plate

There are six commonly referenced pressure tapping types associated with orifice flow measurement:

Flange Taps

Vena Contracta Taps

Radius Taps

Pipe Taps (Full Flow Taps)

Corner Taps

Elbow Taps

We will understand each one clearly.

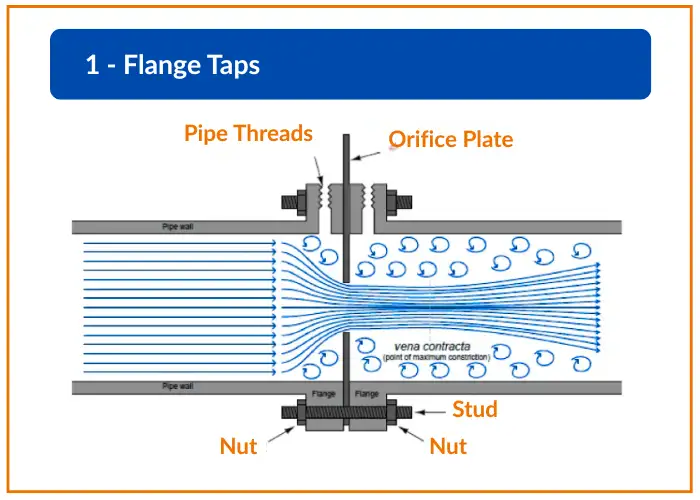

1. Flange Taps

Flange taps are the most widely used pressure tappings in orifice plate installations.

They are positioned:

One inch upstream of the orifice plate

One inch downstream of the orifice plate

For pipe sizes greater than 2 inches, this one-inch rule applies regardless of pipe diameter.

Important points:

Not recommended for pipe sizes below 1.5 inches

Generally avoided below 2 inches

Very common in North America

Why are they popular?

Easy to machine in flanges

Repeatable geometry

Well standardized in ISO and ASME

In real industrial installations, if you open an orifice meter run, most likely you will see flange taps.

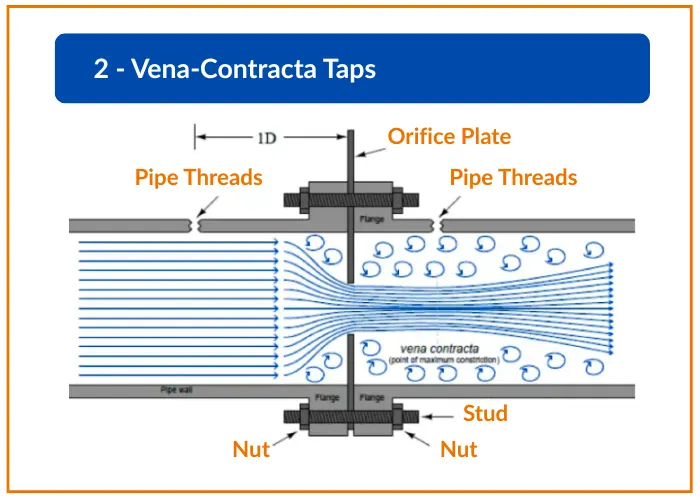

2. Vena Contracta Taps

After fluid passes through the orifice, the narrowest jet forms slightly downstream. This point is called the vena contracta.

Here:

Pressure is minimum

Velocity is maximum

In vena contracta tapping:

Upstream tap is placed one pipe diameter upstream

Downstream tap is placed at the point of minimum pressure

These taps aim to capture the maximum possible differential pressure.

However:

Exact vena contracta location varies with beta ratio

Not as standardized as flange taps

Installation accuracy becomes critical

They are sometimes preferred in smaller pipe diameters where maximizing DP is necessary.

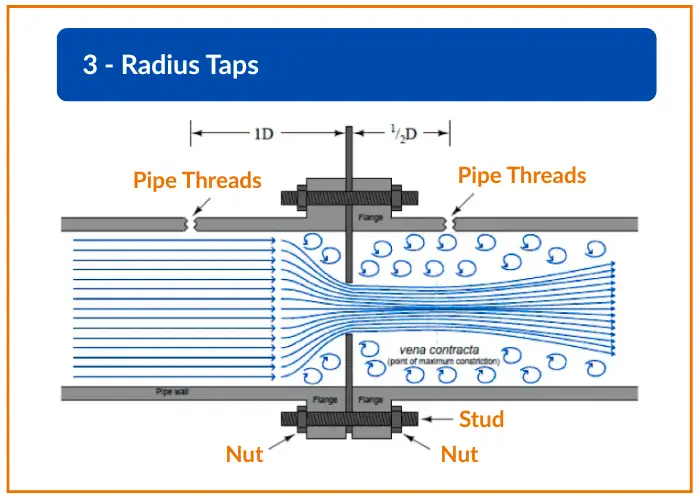

3. Radius Taps

Radius taps are more formalized and geometrically defined.

Their positions are:

Upstream tap at 1 pipe diameter (1D) upstream

Downstream tap at 0.5 pipe diameter (0.5D) downstream

These taps are typically recommended for:

Pipe sizes 6 inches or larger

Situations requiring better standard compliance

Compared to flange taps:

They are located further away

Less influenced by flange machining tolerance

In high accuracy flow measurement systems, radius taps are often preferred.

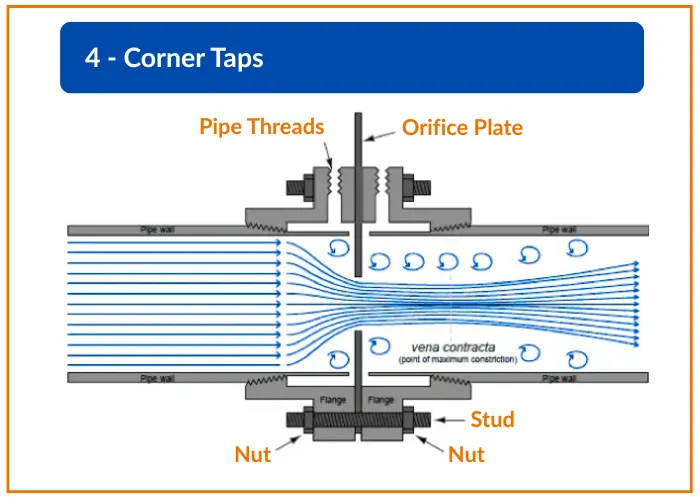

4. Corner Taps

Corner taps are positioned directly at the faces of the orifice plate.

In other words:

Upstream tap is located at the upstream face

Downstream tap is located at the downstream face

They are very similar to flange taps but physically located at the plate edge.

Usage differences:

In Europe, corner taps are used for all pipe diameters

In North America, mainly used for pipe sizes below 2 inches

Advantages:

Very compact design

Suitable for small line sizes

Good repeatability

If you are working on small bore piping, corner taps are usually the preferred choice.

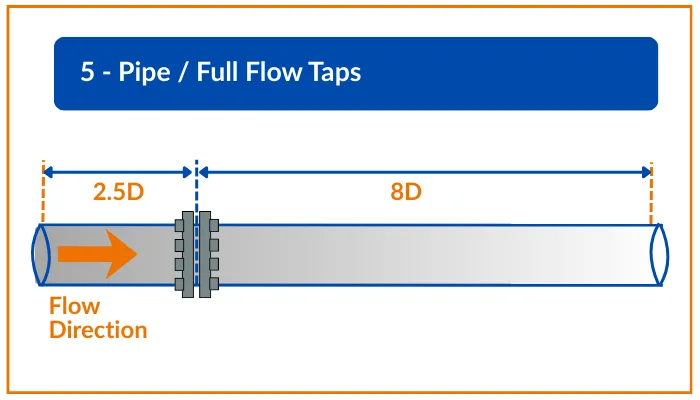

5. Pipe Taps (Full Flow Taps)

Pipe taps are located further away from the orifice plate.

Typical locations:

2.5 pipe diameters upstream

8 pipe diameters downstream

Because they are not close to the orifice flange:

Exact location tolerance is less critical

However, measurement error can be higher

Pressure recovery may influence reading

These taps were more common in older installations.

In modern standardized systems, flange or corner taps are more preferred.

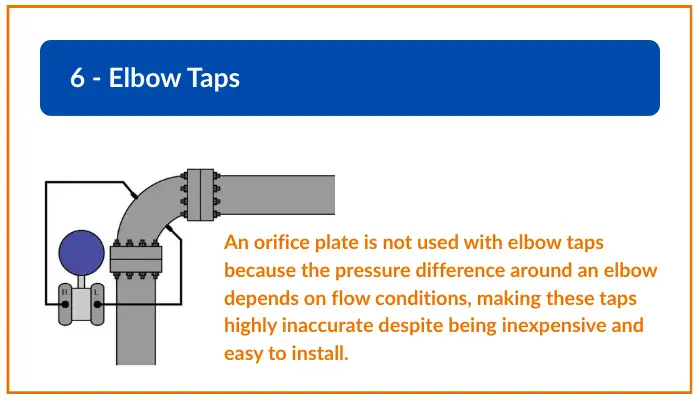

6. Elbow Taps

Elbow taps are different from the previous types.

Here:

No orifice plate is used

Pressure difference is measured across an elbow

When fluid flows around an elbow:

Centrifugal force creates pressure difference

Outer side pressure is higher

Inner side pressure is lower

Although:

They are inexpensive

Easy to install

They are:

Not highly accurate

Very sensitive to flow profile

Not recommended for custody transfer

Elbow taps are generally used where cost is more important than high accuracy.

Comparison of Pressure Tappings in Orifice Plate

Let us summarize key practical differences:

Flange Taps – Most common and standardized

Corner Taps – Best for small diameter pipes

Radius Taps – Used in larger pipes with better geometry control

Vena Contracta Taps – Capture maximum DP but less standardized

Pipe Taps – Older design, more measurement variation

Elbow Taps – Low cost but lower accuracy

How to Select the Right Pressure Tapping?

Selecting pressure tappings in orifice plate depends on:

Pipe Diameter

Industry Standard Requirement

Required Accuracy

Space Availability

Type of Fluid

For example:

If pipe size is below 2 inches, corner taps are preferred.

If pipe size is above 6 inches and high accuracy is required, radius taps are recommended.

If following ISO 5167 strictly, tapping type must match calculation constants.

Always remember:

Changing tapping type changes discharge coefficient.

You cannot replace flange taps with pipe taps without recalculation.

What we learn today?

Pressure tappings in orifice plate systems may look like a small detail.

But in reality, they define the entire measurement accuracy.

Many times, engineers focus only on beta ratio and plate thickness. They forget tapping geometry.

In instrumentation, precision is not only about expensive transmitters.

It is about correct positioning.

If you understand pressure tapping types clearly, you can:

Design better meter runs

Avoid calibration issues

Reduce measurement uncertainty

Improve plant performance

Flow measurement is science.

Pressure tapping location is geometry.

And geometry defines accuracy.

I hope you like above blog. There is no cost associated in sharing the article in your social media. Thanks for Reading !! Happy Learning