Table of Contents

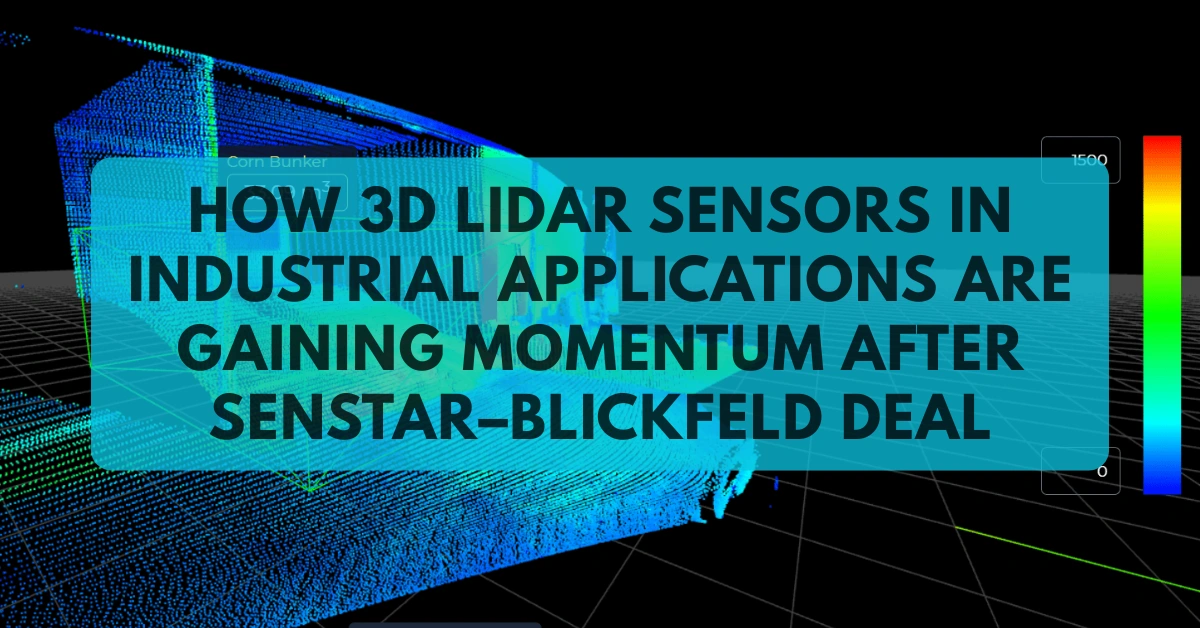

ToggleThe industrial automation world is seeing a steady shift toward smarter and more accurate sensing technologies. One of the most interesting recent developments is the growing use of 3D LiDAR sensors in industrial applications.

This trend received strong attention after Senstar, a Canada-based company from Ottawa, announced its agreement to acquire Blickfeld, a German manufacturer known for advanced 3D LiDAR sensor technology.

This cross-border move between Canada and Germany is more than just a business transaction.

It clearly shows how important LiDAR sensor technology is becoming for modern industrial sensing systems, safety monitoring, and automation.

What is Driving Interest in 3D LiDAR Sensors

LiDAR stands for Light Detection and Ranging. It works by sending laser pulses and measuring the time taken for the light to return after hitting an object. Using this method, LiDAR systems can create highly accurate three-dimensional maps of surroundings.

Earlier, LiDAR was mainly associated with autonomous vehicles and geographical mapping. But today, industries are discovering how useful this technology can be inside plants, warehouses, logistics centers, and outdoor industrial facilities.

3D LiDAR sensors in industrial applications are now used for detecting object movement, monitoring restricted zones, measuring volumes, and improving machine safety systems. Compared to traditional sensors, LiDAR can cover large areas and provide detailed spatial information in real time.

This ability makes it very attractive for industries where both safety and automation efficiency are critical.

Who Are Senstar and Blickfeld

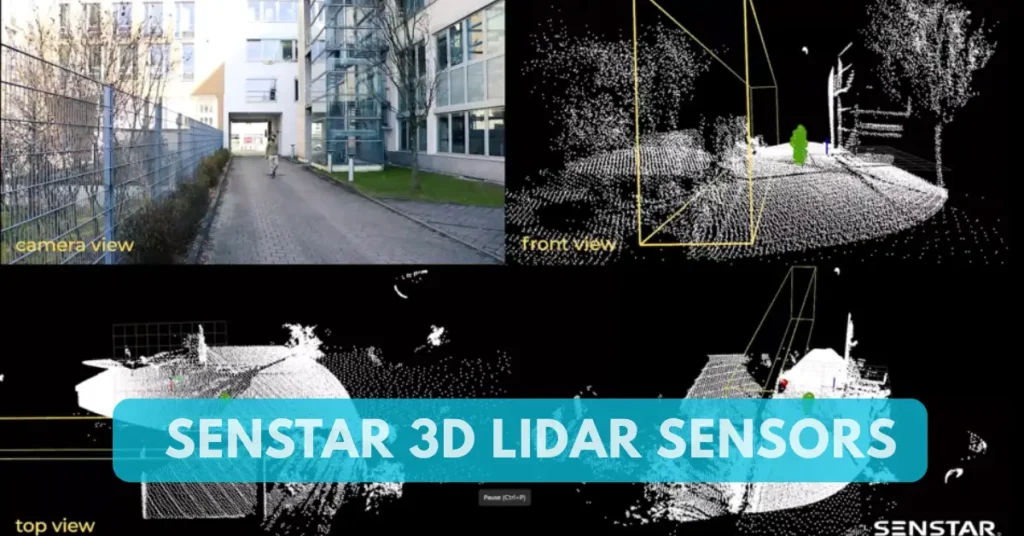

Senstar is well known for perimeter intrusion detection and security solutions used in infrastructure, energy facilities, and industrial sites. Their systems are already installed in many critical facilities where safety is a top priority.

Blickfeld, based in Germany, specializes in compact and high-performance 3D LiDAR sensors. The company focuses on solid-state LiDAR designs that are robust, precise, and suitable for harsh industrial environments.

By combining Senstar’s expertise in security systems with Blickfeld’s sensor technology, the new group can offer complete sensing solutions instead of only detection software or hardware alone.

This combination is especially important for industries looking for integrated automation and safety monitoring platforms.

Why This Deal Matters to Instrumentation Engineers

For instrumentation professionals, this news is important because it signals a shift in sensing strategies. Traditional industrial sensors like photoelectric sensors, ultrasonic sensors, and radar still play a major role, but they have limitations in complex environments.

LiDAR can provide detailed distance measurement across wide fields, detect multiple objects at once, and function reliably in both indoor and outdoor conditions. This allows better monitoring of:

• Conveyor systems and material movement

• Vehicle traffic in plants and ports

• Personnel safety zones

• Storage volume in silos or open yards

This means future instrumentation systems may include more LiDAR-based measurements alongside conventional flow, level, and proximity sensors.

Engineers will need to understand how LiDAR integrates with PLC, DCS, and industrial networks, and how its data can be used for automation logic and alarms.

Impact on Industrial Safety and Automation

Safety regulations are becoming stricter across industries. Companies are expected to prevent accidents, control unauthorized access, and monitor hazardous zones continuously.

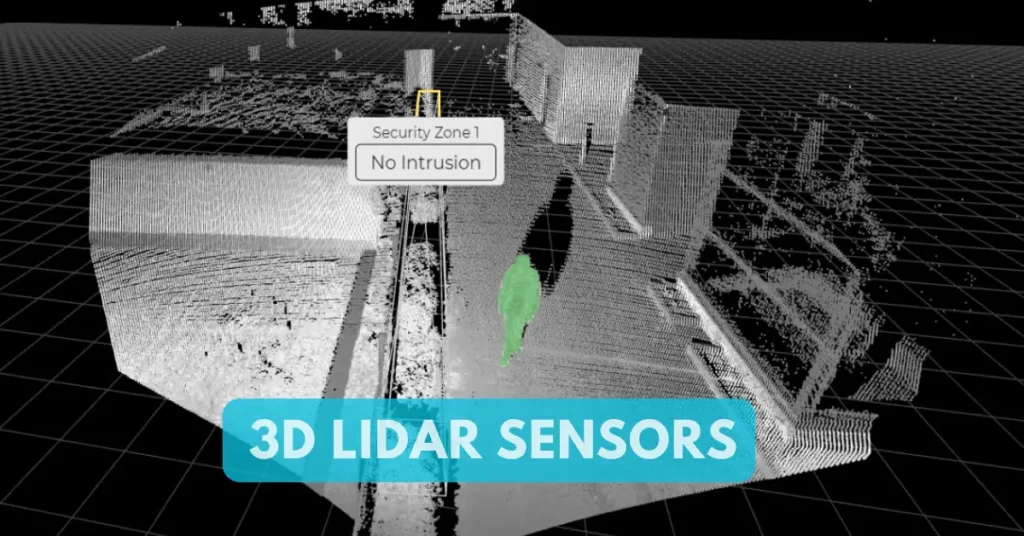

3D LiDAR sensors in industrial applications help improve safety by offering precise area scanning instead of single-point detection. Instead of just knowing that something crossed a beam, operators can see where and how an object is moving.

This improves response time and reduces false alarms.

In automation, LiDAR can help machines understand their surroundings better. For example, robots can adjust movement paths if obstacles appear. Automated vehicles can navigate safely inside factories. Storage systems can monitor inventory volume without manual checks.

This makes LiDAR not just a safety tool but also a productivity enhancer.

Why Germany and Canada Collaboration is Important

Germany is globally known for industrial automation, machine building, and precision engineering.

Canada has strong expertise in infrastructure security and industrial monitoring systems.

This collaboration reflects how sensor development and system integration are becoming globally connected. Innovations in one country are quickly adopted and scaled in others.

For industrial customers, this means faster access to new sensing technologies and better system compatibility across international plants.

For suppliers and distributors, it also means competition will increase, pushing more companies to invest in smart sensor portfolios.

What This Means for the Future of Industrial Sensors

The acquisition suggests that industrial sensors are moving beyond simple detection and into full environmental awareness. Instead of measuring only one variable, future sensors will provide multi-dimensional data.

This aligns well with Industry 4.0 concepts where machines are expected to understand their surroundings, not just process signals.

Data from LiDAR can also support predictive maintenance, digital twins, and advanced analytics platforms. When combined with AI systems, LiDAR data can help identify abnormal behavior patterns in machines or material flows.

This opens new opportunities for system integrators and automation engineers to build smarter control strategies.

Challenges That Still Exist

Even though LiDAR offers many advantages, it also comes with challenges. The cost is still higher compared to basic industrial sensors. Data processing requires more computing power and proper filtering.

Environmental conditions like dust, steam, or heavy fog can affect laser-based measurements. This means LiDAR will not replace all traditional sensors but will work alongside them in selected applications.

Proper system design, calibration, and maintenance will be important to get reliable results.

This is where skilled instrumentation engineers will continue to play a critical role.

News Summary

The Senstar–Blickfeld agreement clearly shows that 3D LiDAR sensors in industrial applications are no longer limited to research labs or autonomous cars. They are becoming part of real production and safety systems.

As industries demand better visibility, higher safety, and smarter automation, sensing technologies will continue to evolve beyond simple switches and transmitters.

For the instrumentation community, this is a good time to start learning about LiDAR principles, integration methods, and application limits. The future of measurement is moving toward full spatial awareness, and LiDAR is playing a strong role in that journey.