Table of Contents

ToggleAbout Nuclear Level Measurement

In many industrial processes, measuring level looks simple but until the process conditions turn extreme. Very high temperature, extreme pressure, toxic chemicals, thick vessel walls, heavy buildup, or violent turbulence can make most conventional level instruments fail repeatedly.

This is where Nuclear Level Measurement quietly proves its value.

Nuclear level measurement is not complex, dangerous, or mysterious when properly understood. In fact, it is one of the most reliable and maintenance-free level measurement techniques used in critical industries worldwide.

This article explains Nuclear Level Measurement, how it works, where it is used, its advantages, limitations, and why it is often chosen when all other technologies fail.

What Is Nuclear Level Measurement?

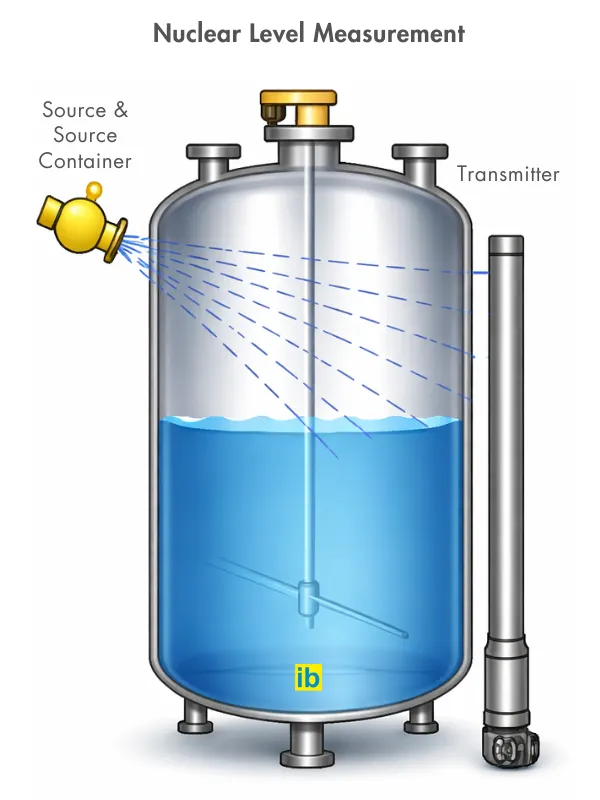

Nuclear level measurement is a non-contact, non-intrusive level measurement technique that uses gamma radiation to determine the level inside a vessel.

Unlike radar, ultrasonic, differential pressure, or displacer-based systems, nuclear level measurement does not touch the process at all.

The radiation source and detector are mounted outside the vessel, making this technology ideal for the harshest industrial environments.

The basic idea is simple: As the level inside the vessel changes, the amount of radiation reaching the detector also changes. This change is then converted into a level signal.

How Nuclear Level Measurement Works

The working principle is based on radiation attenuation. Gamma rays lose intensity as they pass through matter.

The process can be understood step by step:

A radioactive source emits gamma radiation in a controlled direction

These gamma rays pass through the vessel wall and process material

The process material absorbs part of the radiation

A detector on the opposite side measures the remaining radiation

Higher level means more absorption and lower radiation at the detector

Lower level means less absorption and higher radiation at the detector

This variation in detected radiation is converted into an electrical signal, typically 4–20 mA, representing the level.

Main Components of a Nuclear Level Measurement System

A nuclear level measurement system is simple in construction but extremely robust.

Radiation Source

A sealed radioactive isotope (commonly Cesium-137 or Cobalt-60) emits gamma radiation. The source strength is carefully selected based on vessel size and process conditions.Source Housing and Shielding

The source is placed inside a heavily shielded housing that directs radiation only toward the vessel and prevents exposure in other directions.Detector

The detector receives gamma radiation after it passes through the vessel. Scintillation detectors are commonly used due to their sensitivity and stability.Signal Processing Unit

The detector signal is processed and converted into a usable output such as 4–20 mA, HART, or digital communication.Mounting Arrangement

Both source and detector are externally mounted, usually clamped or bolted, without any process penetration.

Types of Nuclear Level Measurement

Nuclear level measurement is not limited to just one application type.

Point Level Measurement

Used for high-level or low-level detection, often as a safety interlock or alarm.Continuous Level Measurement

Provides continuous level output across the full vessel height.Density Measurement

By measuring radiation attenuation, density variations in liquids or slurries can be determined.Interface Level Measurement

Used to measure interface between two fluids with different densities, such as oil and water.

Why Nuclear Level Measurement Is Used When Others Fail

Many engineers turn to nuclear level measurement only after repeated failures with conventional technologies. There are clear reasons for this.

Extremely high temperatures where electronics or probes cannot survive

Very high pressures that damage internal sensors

Highly corrosive or toxic chemicals

Heavy buildup, coating, or scaling on vessel walls

Violent agitation, foaming, or turbulence

Thick-walled or refractory-lined vessels

Since nuclear level measurement does not touch the process, none of these conditions affect its performance.

Advantages of Nuclear Level Measurement

Despite its specialized nature, nuclear level measurement offers several strong advantages.

Completely non-contact and non-intrusive

Works reliably in extreme process conditions

No moving parts and very low maintenance

Immune to pressure, temperature, foam, and buildup

Ideal for hazardous and toxic applications

Long-term stability and repeatability

In critical applications, reliability is more important than cost and this is where nuclear level measurement excels.

Limitations and Concerns

Like any technology, nuclear-level measurement also has limitations.

Regulatory approvals and licensing are mandatory

Initial cost is higher than conventional instruments

Special handling and documentation required

Radiation source disposal at end of life

Public perception and misunderstanding about radiation

However, these limitations are administrative and procedural and not technical.

Safety Aspects in Nuclear Level Measurement

Safety is the first concern whenever radiation is involved. Modern nuclear-level measurement systems are designed with strict safety controls.

Radiation sources are fully sealed and shielded

Radiation exposure levels are extremely low

Installation follows international radiation safety standards

Handling is performed only by licensed personnel

Regular leak testing ensures source integrity

When installed and maintained correctly, nuclear level measurement is one of the safest level technologies in operation.

Typical Industrial Applications

Nuclear-level measurement is commonly used in industries where failure is not an option.

Chemical reactors and distillation columns

Oil and gas separators and knockout drums

High-pressure boilers and feedwater systems

Hazardous chemical storage tanks

Cement, mining, and mineral processing plants

Power generation and steel industries

In many of these applications, no alternative technology can operate reliably.

Nuclear Level Measurement vs Other Level Technologies

Compared to radar, ultrasonic, or differential pressure systems, nuclear-level measurement stands apart.

Radar and ultrasonic systems require clear signal paths and are affected by foam, vapor, or turbulence. Differential pressure systems depend on stable density. Nuclear level measurement is unaffected by all of these factors.

This is why it is often selected as a last-resort solution but once installed, it often becomes the most reliable one.

When Should You Choose Nuclear Level Measurement?

Nuclear level measurement should be considered when:

Process conditions destroy conventional sensors

Vessel penetration is not allowed

Maintenance access is difficult or unsafe

Safety and reliability are more important than cost

Regulatory approvals are manageable

It is not the first choice—but it is often the best final choice.

What we learn today?

Nuclear Level Measurement is one of the most misunderstood technologies in instrumentation. It is not dangerous, complicated, or outdated. Instead, it is a highly engineered, safety-controlled, and extremely reliable solution for the toughest level measurement challenges.

When extreme conditions make other instruments fail repeatedly, nuclear level measurement continues to perform quietly, consistently, and accurately.

For instrument engineers working in critical industries, understanding this technology is not optional but it is essential.

I hope you like above blog. There is no cost associated in sharing the article in your social media. Thanks for Reading !! Happy Learning