Table of Contents

ToggleWhy the Right Flow Characteristic Decides Control Quality

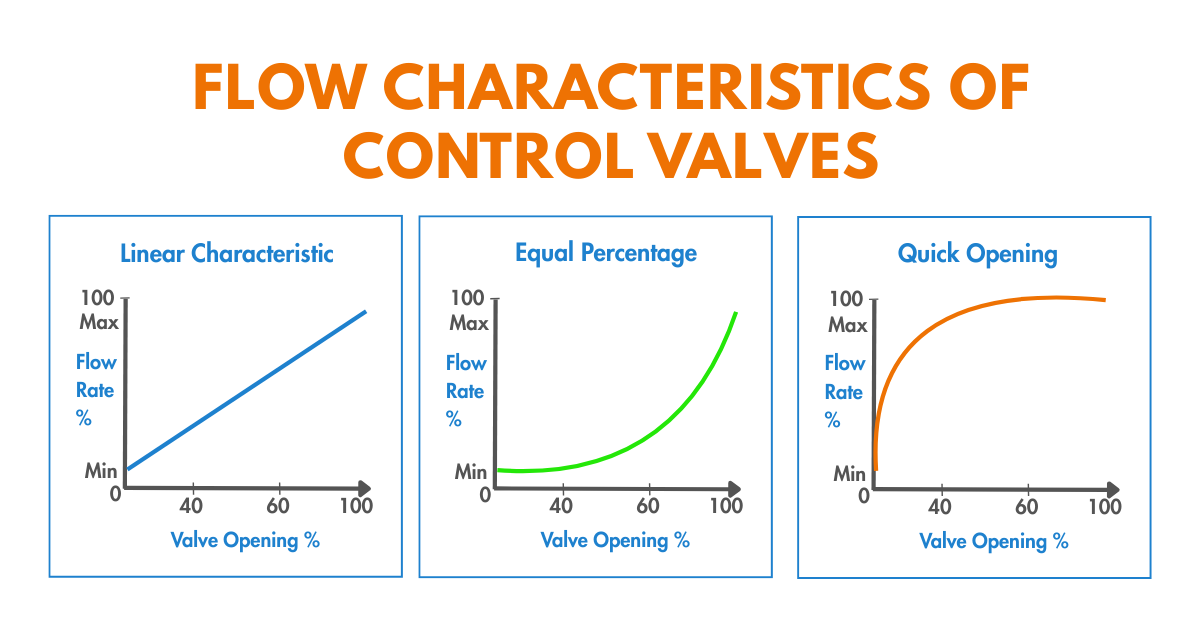

Selecting the correct flow characteristic is one of the most underestimated steps in control valve selection. In many plants, unstable loops, hunting valves, and poor control are blamed on tuning or instrumentation when the real problem is an incorrect flow characteristic.

This article explains all six common and modern flow characteristics in depth, focusing on how they behave in real processes.

What Are Flow Characteristics?

Flow characteristics define the relationship between:

Valve travel (%)

Flow rate (%) through the valve

They describe how much the flow changes for a given change in valve opening. This directly affects valve gain, which in turn determines how easy or difficult it is to control a process.

Flow characteristics are usually defined at constant pressure drop across the valve. However, most industrial systems do not operate at constant pressure drop, this is why choosing the right characteristic is very important.

1. Linear Flow Characteristic

A linear flow characteristic means that flow increases directly in proportion to valve travel. If the valve opens by 20%, the flow increases by approximately 20%.

How Linear Valves Behave in Real Systems

Valve gain remains nearly constant across the stroke

Response is predictable and easy to understand

Controller output and flow change have a direct relationship

In systems where pressure drop across the valve remains relatively constant, linear valves behave very well and are easy to tune.

Typical Applications of Linear Valves

Level control in tanks and vessels

Mixing and blending of liquids

Split-range control applications

Systems with stable hydraulic resistance

Advantages of Linear Flow Characteristic

Simple and intuitive control behavior

Minimal nonlinear effects

Ideal for slow, integrating processes

Limitations of Linear Flow Characteristic

Poor performance when system pressure drop varies significantly

Can become aggressive at low flows in real piping systems

Limited turndown capability compared to equal percentage valves

2. Equal Percentage Flow Characteristic

The equal percentage characteristic is the most commonly used in industrial control valves.

Here, each equal increment of valve travel produces an equal percentage change in flow, not an equal absolute change.

How Equal Percentage Valves Behave

Small flow change at low valve openings

Larger flow change as valve opening increases

Valve gain increases progressively with stroke

This behavior closely matches how most piping systems behave, where pressure drop increases with flow.

Why Equal Percentage Works So Well in Practice

In real processes, as flow increases, system resistance increases. Equal percentage valves automatically compensate for this, resulting in a more linear overall loop response.

Typical Applications of Equal Percentage Valves

Flow control loops

Pressure control systems

Steam and gas services

Most general-purpose control applications

Advantages of Equal Percentage Characteristic

Excellent rangeability

Stable control over wide operating ranges

Best choice for variable load processes

Limitations of Equal Percentage Characteristic

Reduced sensitivity at very low flows

Not ideal for systems with truly constant pressure drop

3. Quick Opening Flow Characteristic

A quick opening characteristic delivers a large flow increase at very small valve openings.

This type of characteristic is not intended for throttling control.

How Quick Opening Valves Behave

Very high valve gain near closed position

Flow increases rapidly at small travel

Minimal flow change at higher openings

Typical Applications of Quick Opening Valves

On/off service

Emergency shutdown systems

Safety and relief applications

Bypass and startup lines

Advantages of Quick Opening Characteristic

Rapid establishment of full flow

Simple control logic

Reliable for binary operation

Limitations of Quick Opening Characteristic

Extremely poor throttling performance

High risk of oscillation in modulating control

Unsuitable for precise flow regulation

4. Modified Parabolic Flow Characteristic (Modern)

The modified parabolic characteristic is a modern development designed to balance control stability and rangeability.

It lies between linear and equal percentage behavior.

How Modified Parabolic Valves Behave

Smooth nonlinear flow response

Moderate valve gain at low travel

Controlled gain increase at higher travel

This characteristic avoids the aggressive behavior of linear valves and the low sensitivity of equal percentage valves at small openings.

Typical Applications of Modified Parabolic Valves

Temperature control loops

Heat exchangers and thermal systems

Energy-efficient process control

HVAC and utility services

Advantages of Modified Parabolic Characteristic

Improved stability over wide operating ranges

Better low-flow control than equal percentage

Reduced energy losses

5. Linear–Equal Percentage Hybrid Characteristic

Hybrid characteristics combine linear behavior at low travel with equal percentage behavior at higher travel.

These are achieved using specially designed valve trims.

How Hybrid Valves Behave

Precise control near closed position

Wide rangeability at higher flows

Adaptive response to changing process loads

Typical Applications of Hybrid Valves

Processes with frequent load variations

Systems requiring wide turndown ratios

Advanced process control loops

Advantages of Hybrid Characteristics

Improved controllability across entire valve stroke

Reduced tuning effort

Better disturbance rejection

6. Hyperbolic Flow Characteristic (Special Applications)

Hyperbolic flow characteristics are used only in specialized and engineered processes.

How Hyperbolic Valves Behave

Highly nonlinear response

Valve gain changes sharply with travel

Designed for very specific process behavior

Typical Applications of Hyperbolic Valves

Custom chemical processes

Unique flow-pressure relationships

Special safety or experimental systems

Advantages and Limitations

Tailored performance for unique needs

Not suitable for general industrial use

Requires detailed process modeling

Inherent Control Valve Flow Characteristics

Control valve manufacturers specify only the inherent flow characteristics of a control valve. These characteristics describe the relationship between valve travel (opening position) and flow rate, assuming that the pressure drop across the valve remains constant.

In reality, a nearly constant pressure drop across the control valve is possible only when most of the system pressure loss occurs at the valve itself and not along the piping.

This condition would require:

Very short pipeline lengths

Minimal fittings such as elbows, reducers, or tees

No additional pressure-reducing equipment installed in series with the control valve

Such an arrangement is rarely achievable in real plant installations.

In actual processes, pressure losses are distributed across pipelines, fittings, heat exchangers, and other equipment. Therefore, the pressure drop across the control valve continuously changes with flow.

The only place where a truly constant pressure drop exists is in manufacturer test laboratories, where control valves are tested using extremely short piping setups.

For this reason, the flow characteristics published by valve manufacturers are known as inherent control valve flow characteristics, they represent idealized behavior under controlled test conditions, not real-world installations.

Installed Control Valve Flow Characteristics

Installed control valve flow characteristics describe the relationship between valve travel (opening position) and the actual volumetric flow rate through the valve under real operating conditions, where the pressure drop across the valve continuously changes.

Unlike laboratory test conditions, the pressure drop across a control valve in a real plant is not constant. As the valve opens or closes, the pressure drop is influenced by many elements installed in series with the valve, such as:

Pipeline length

Pipe fittings like elbows, reducers, and tees

Other valves installed upstream or downstream

Flow meters and process equipment

In most piping systems, the pressure drop across these components varies approximately with the square of the flow rate. As a result, the portion of total system pressure drop available across the control valve keeps changing as flow changes.

Because of this, the ideal condition of constant valve pressure drop exists only in manufacturer test laboratories, where control valves are tested using very short and simplified piping arrangements.

Under such ideal conditions, a control valve exhibits its inherent flow characteristic. However, once the same valve is installed in an actual process, it behaves according to its installed flow characteristic.

In many cases, the installed flow characteristic can be significantly different from the inherent characteristic published in the manufacturer’s datasheet. This difference is one of the main reasons why a control valve that looks perfect on paper may perform poorly in real plant operation.

How Flow Characteristics Impact Control Performance

Flow characteristics directly affect loop stability. Incorrect selection can lead to:

Valve hunting and oscillations

Excessive overshoot

Poor control near setpoint

Increased wear on valve internals

Correct selection results in:

Smooth valve movement

Stable and predictable control

Reduced maintenance costs

Improved process efficiency

Practical Selection Guidelines

Linear → Level control and constant pressure drop systems

Equal Percentage → Flow and pressure control with variable loads

Quick Opening → On/off and safety applications

Modified & Hybrid → Temperature control and energy optimization

Hyperbolic → Only for engineered special cases

In control valve selection, flow characteristic is not a secondary choice.

A correctly selected flow characteristic:

Improves control loop stability

Extends valve life

Enhances overall plant efficiency

Many control problems disappear simply by choosing the right flow characteristic for the process—before touching the controller tuning.

I hope you like above blog. There is no cost associated in sharing the article in your social media. Thanks for Reading !! Happy Learning