Table of Contents

ToggleAnalog Vs Digital Instrumentation System: Introduction

Instrumentation systems play a very important role in modern industry.

From measuring temperature and pressure in a boiler to monitoring flow in pipelines and controlling complex chemical processes, instrumentation makes automation possible.

Broadly, all measurement systems can be classified into analog and digital instrumentation systems.

Both systems are used to measure physical quantities, but they differ greatly in performance, accuracy, data handling, and integration with automation systems.

In this article, we will clearly understand what analog and digital instrumentation systems are, how they work, their differences, advantages, limitations, and their real-life industrial applications.

What is an Instrumentation System?

An instrumentation system is a system used to measure, monitor, display, and control physical parameters such as:

- Temperature

- Pressure

- Flow

- Level

- Speed

- Voltage

- Current

It converts a physical quantity into a usable signal that can be displayed, recorded, or used for control purposes. Instrumentation systems form the backbone of industrial automation, power plants, oil & gas, chemical industries, pharmaceuticals, water treatment plants, and manufacturing industries.

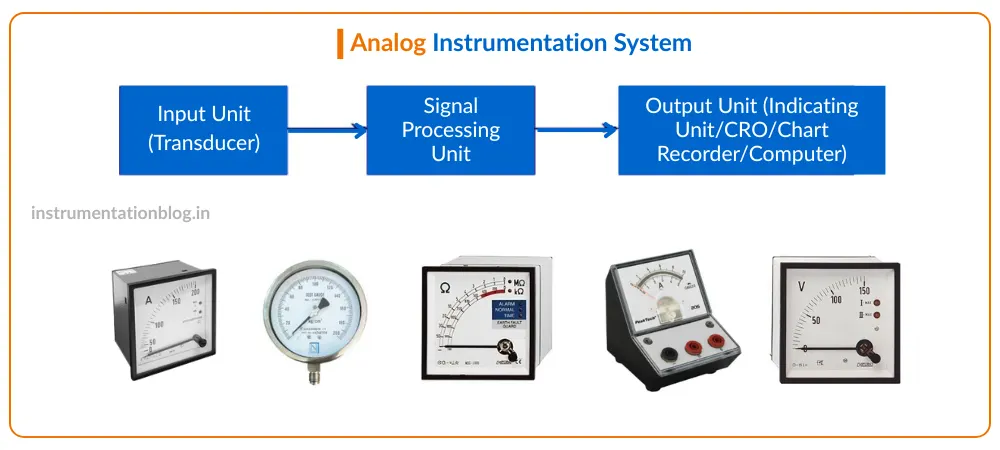

What is an Analog Instrumentation System?

An analog instrumentation system represents the measured quantity in a continuous form.

The output changes smoothly with changes in the input. Most traditional instruments such as analog voltmeters, pressure gauges, and recorders work on this principle.

Basic Working of an Analog Instrumentation System

Primary Element / Transducer

Senses the physical quantity (like temperature or pressure) and converts it into an electrical signal.Signal Conditioning Unit

Amplifies, filters, or modifies the signal so it becomes suitable for display.Output Device

Displays the signal as a pointer moving over a scale or as a continuous waveform.

Key Characteristics of Analog Systems

- Continuous signal output

- Mechanical movement in many instruments

- Visual scale reading

- Susceptible to noise and environmental effects

What is a Digital Instrumentation System?

A digital instrumentation system represents the measured quantity in discrete numerical form.

The output is displayed as numbers instead of pointer movement. Modern industries heavily rely on digital instruments due to their accuracy and automation capability.

Basic Working of a Digital Instrumentation System

Transducer

Converts physical quantity into an electrical signal.Signal Conditioning Unit

Processes and amplifies the signal.Multiplexer (in multi-input systems)

Selects one signal at a time.Analog-to-Digital (A/D) Converter

Converts the analog electrical signal into digital binary form.Digital Display / Computer Interface

Displays the measured value numerically or sends data to PLC, SCADA, or computers.

Key Characteristics of Digital Systems

- Discrete numerical output

- High accuracy and resolution

- Data storage and communication capability

- Easy integration with control systems

Analog Vs Digital Instrumentation Systems

| Feature | Analog System | Digital System |

|---|---|---|

| Signal Type | Continuous | Discrete |

| Output Display | Pointer and scale | Numeric display |

| Accuracy | Moderate | High |

| Noise Immunity | Low | High |

| Data Storage | Difficult | Easy |

| Data Logging | Manual | Automatic |

| Transmission Distance | Limited | Long-distance possible |

| PLC / SCADA Integration | Limited | Fully compatible |

| Maintenance | High | Low |

| Size | Bulky | Compact |

Advantages of Analog Instrumentation Systems

Simple Design – Analog instruments have simple construction and are easy to understand.

Fast Response – They respond instantly to changes in input signal.

Low Initial Cost – Cheaper than most digital systems.

No Conversion Delay – No need for A/D conversion.

Continuous Indication – Useful for observing trends visually.

Advantages of Digital Instrumentation Systems

High Accuracy and Precision

Digital systems provide accurate numerical readings with minimal human error.Easy Data Storage and Retrieval

Measured data can be stored in memory or transmitted to servers.Noise Immunity

Digital signals are less affected by electrical noise.Remote Monitoring

Data can be accessed from anywhere through networks.Easy Integration

Works smoothly with PLC, DCS, SCADA, and IIoT platforms.Low Maintenance

No mechanical wear and tear.Compact Size

Requires less space and wiring.

Limitations of Analog Instrumentation Systems

Low Accuracy Due to Mechanical Errors

Analog instruments rely on moving parts that suffer from friction, wear, and aging, which reduces long-term accuracy.Parallax Error While Reading

Reading errors occur when the pointer is not viewed from the correct angle, leading to incorrect measurements.Affected by Vibration and Temperature

External vibration and temperature variations disturb mechanical movement and affect measurement stability.Difficult to Log or Store Data

Analog systems do not support automatic data recording, making long-term data storage and analysis difficult.Not Suitable for Modern Automation

These systems cannot directly integrate with PLC, SCADA, or digital control platforms.Limited Remote Monitoring Capability

Physical presence is required to read analog instruments, making remote monitoring impossible.

Limitations of Digital Instrumentation Systems

Higher Initial Cost

Digital instrumentation systems require higher investment for instruments, installation, and supporting infrastructure.Requires Stable Power Supply

Continuous and stable electrical power is essential for proper functioning of digital instruments.Sensitive to Extreme Electromagnetic Interference

Very strong EMI can disturb electronic circuits and affect signal processing accuracy.Needs Skilled Personnel for Troubleshooting

Digital systems involve electronics and software, requiring trained professionals for maintenance and fault diagnosis.Conversion Delay in Fast-Changing Signals

A very small delay occurs during analog-to-digital conversion when signals change rapidly.

Applications of Analog Instrumentation Systems

Even today, analog instruments are widely used in many industrial and commercial areas.

Mechanical Pressure Gauges in Pipelines

Used for local pressure indication in water, steam, oil, and gas pipelines.Analog Speedometers in Older Vehicles

Provide continuous indication of vehicle speed using mechanical or electromechanical systems.Analog Voltmeters and Ammeters in Laboratories

Used for basic electrical measurements during testing and educational experiments.Chart Recorders for Continuous Monitoring

Used to record parameters like temperature, pressure, and flow over time on paper charts.Level Indicators in Storage Tanks

Provide visual indication of liquid level in tanks and vessels.Boiler Pressure and Temperature Gauges

Used for real-time safety monitoring in boilers and steam systems.

Applications of Digital Instrumentation Systems

Digital instrumentation systems are widely used in modern industries where accuracy, automation, and data handling are critical.

PLC and DCS Based Automation Systems

Used for real-time monitoring and control of industrial processes in manufacturing plants.Smart Pressure, Flow, Level, and Temperature Transmitters

Provide high-accuracy digital output with communication protocols like HART, Modbus, and Profibus.SCADA and Remote Monitoring Systems

Used for centralized monitoring and control of large plants and remote installations.Energy and Power Monitoring Systems

Used in electrical substations and industries for measuring voltage, current, power, and energy consumption.Oil and Gas Industry

Used for pipeline monitoring, custody transfer measurement, and safety systems.Water and Wastewater Treatment Plants

Used for automatic control of flow, level, pressure, and water quality parameters.Pharmaceutical and Food Processing Industries

Used for precise control of temperature, pressure, and batch processes.Research Laboratories and Testing Centers

Used for high-precision measurements, data acquisition, and analysis.

Which is Better: Analog or Digital Instrumentation System?

There is no absolute answer to this question. The choice depends on the application, budget, accuracy requirement, and automation need.

- If you need simple measurement with low cost, analog systems are suitable.

- If you need high accuracy, data storage, automation, and remote monitoring, digital systems are the best choice.

In modern industries, digital systems dominate, but analog instruments still serve as backup indicators and local safety instruments.

What we learn today?

Both analog and digital instrumentation systems play very important roles in measurement and control.

Analog systems are simple, economical, and provide direct visual trends, while digital systems offer high precision, data storage, automation, and remote monitoring.

Modern industries depend heavily on digital instrumentation for process optimization and safety, but analog instruments still remain relevant in many field applications.

Understanding the differences between these two systems helps engineers, technicians, and students select the right measurement system for each application.

I hope you like above blog. There is no cost associated in sharing the article in your social media. Thanks for Reading !! Happy Learning