Table of Contents

ToggleDrain and Vent Hole: Introduction

Orifice plates are one of the most widely used primary flow measuring elements in industries such as oil & gas, power plants, water treatment, chemicals, and HVAC systems.

Even though the orifice plate design looks very simple, small design features like drain and vent holes play a very important role in improving measurement accuracy and protecting the system.

Many students and even field technicians often ask:

1) Why do we need a drain hole in an orifice plate?

2) What is the purpose of a vent hole?

3) Can these small holes affect flow measurement accuracy?

In this article, you will clearly understand:

=> What drain holes and vent holes are

=> Why they are required

=> Where they are used

=> Their impact on accuracy

=> Limitations and alternatives

What Is an Orifice Plate?

Before learning about drain and vent holes, let us quickly revise what an orifice plate is.

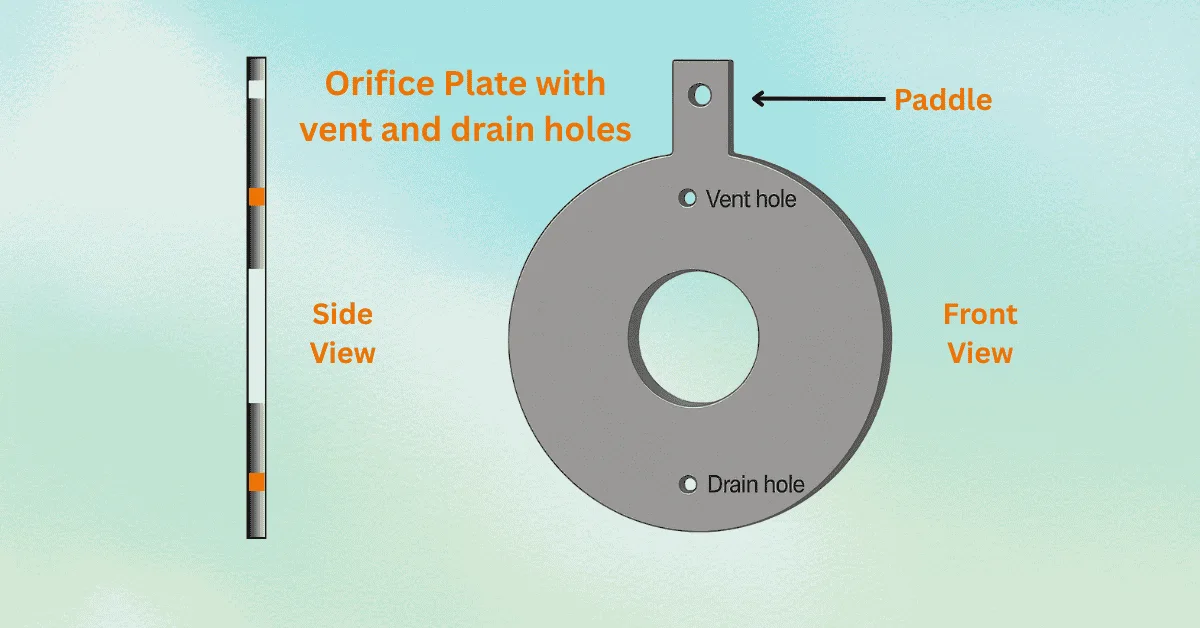

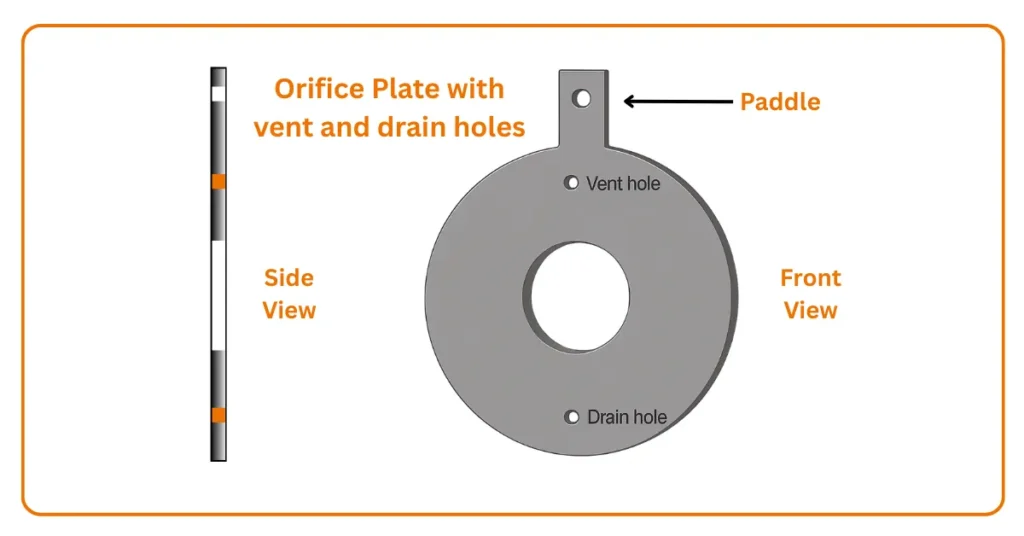

An orifice plate is a thin metal plate with a precisely drilled hole (called the orifice bore) at the center. It is installed in a pipeline to create a pressure drop when fluid flows through it. This pressure drop is measured using a differential pressure transmitter, and from this value, the flow rate is calculated.

Orifice plates are popular because they are:

- Simple in construction

- Low in cost

- Easy to install

- Suitable for liquids, gases, and steam

But one common problem in real industrial processes is phase mixing, such as:

- Liquid present in gas lines

- Gas bubbles present in liquid lines

This is where drain and vent holes become necessary.

What Is a Drain Hole in an Orifice Plate?

A drain hole is a small hole drilled at the bottom (lower side) of the orifice plate. It allows any trapped liquid to drain away from the pipeline.

Why Is a Drain Hole Required?

A drain hole is mainly required in gas flow applications where liquid accumulation may occur. Even in gas pipelines, small amounts of moisture, condensate, or liquid hydrocarbons can collect at the bottom of the pipe.

If this trapped liquid is not removed, it can:

- Disturb the flow pattern

- Cause incorrect differential pressure reading

- Lead to inaccurate flow measurement

- Increase the risk of corrosion or vibration

The drain hole allows this accumulated liquid to pass through instead of collecting upstream of the orifice.

Location of Drain Hole

The drain hole is always provided at the lowest point of the orifice plate, usually at the 6 o’clock position when installed in the pipe. This ensures that gravity helps remove the trapped liquid automatically.

Applications Where Drain Hole Is Used

A drain hole is commonly used in:

- Natural gas pipelines

- Steam lines with condensate

- Compressed air systems

- Wet gas service

- Gas lines in refineries and power plants

In all these systems, liquid carryover is possible, so a drain hole becomes necessary.

Effect of Drain Hole on Flow Measurement Accuracy

One important concern is whether the drain hole affects measurement accuracy.

Yes, the drain hole allows a small amount of unmeasured flow to pass through it. However, industrial standards provide a safe limit.

Standard Accuracy Rule

If the diameter of the drain hole is less than 10% of the main orifice bore, then:

- The unmeasured flow is less than 1%

- The overall flow measurement accuracy remains acceptable

So when properly designed, the drain hole does not significantly affect accuracy.

When Is a Drain Hole NOT Recommended?

A drain hole should NOT be used in:

- Dirty fluids

- Slurries

- Fluids containing solid particles

- Wastewater with suspended solids

In these services, the small drain hole can easily get clogged or plugged, which can cause:

- Improper drainage

- False readings

- Maintenance problems

Alternative to Drain Hole: Eccentric Orifice Plate

Instead of drilling a drain hole, an eccentric orifice plate is often used in dirty or slurry services.

In an eccentric orifice plate:

- The main bore is offset from the center

- The opening touches the bottom of the pipe

- Liquid passes easily without getting trapped

- No small hole is required

- Risk of plugging is reduced

What Is a Vent Hole in an Orifice Plate?

A vent hole is a small hole provided at the top (upper side) of the orifice plate. It allows trapped gas or air bubbles to pass through the plate.

Why Is a Vent Hole Required?

A vent hole is required in liquid flow applications where gas entrapment may occur. Even in liquid pipelines, small gas bubbles or air pockets can be present due to:

- Pump suction

- Temperature changes

- Cavitation

- Entrained air

If gas accumulates upstream of the orifice plate:

- It disturbs the liquid flow pattern

- It causes incorrect pressure drop measurement

- The transmitter may read lower differential pressure

- Flow reading becomes unstable or inaccurate

The vent hole allows this trapped gas to escape safely.

Location of Vent Hole

The vent hole is always provided at the top of the orifice plate, usually at the 12 o’clock position when installed horizontally. This ensures any gas bubbles naturally rise and escape through the vent.

Applications Where Vent Hole Is Used

Vent holes are commonly used in:

- Water pipelines

- Cooling water systems

- Chemical liquid lines

- Boiler feedwater systems

- Liquid process pipelines prone to air entrainment

In all these systems, air or gas bubbles can disturb accurate flow measurement, making vent holes necessary.

Effect of Vent Hole on Accuracy

Just like drain holes, vent holes also allow a small amount of unmeasured flow.

If the vent hole diameter is less than 10% of the main orifice bore:

- Error remains within 1%

- Measurement accuracy is still acceptable for most industrial applications

Thus, properly sized vent holes do not significantly affect flow readings.

When Is a Vent Hole NOT Recommended?

Vent holes should NOT be used in:

- Dirty liquid services

- Slurries

- Fluids with suspended solids

- Fibrous or sticky fluids

Just like drain holes, vent holes can also get plugged, leading to:

- Gas accumulation

- Erratic readings

- Maintenance issues

Alternative to Vent Hole: Eccentric Orifice Plate

For dirty liquid service, an eccentric orifice plate with the opening at the top is used. This allows gases to pass freely without the risk of a small hole getting blocked.

Points to be noted:

1) Use with Prior Approval:

Vent or drain holes in orifice plates should be provided only after prior approval from the plant owner and all concerned stakeholders.

2) ISO/TR 15377 Guideline:

According to ISO/TR 15377, the drain hole diameter must not exceed 10% of the orifice bore (0.1d). Also, no part of the drain hole should lie inside a concentric circle of diameter (D – 0.2d). The pressure tapping points should be oriented between 90° and 180° with respect to the drain hole position.

3) API RP 551 Recommendation:

API RP 551 specifies that the maximum recommended hole area is 0.75% of the orifice bore area. The maximum hole diameter should be 12 mm, and the minimum should be 2.5 mm. Drain or vent holes should not be used in pipelines smaller than 2 inches.

4) API RP 550 Accuracy Limit:

As per API RP 550, if the hole diameter is kept below 10% of the orifice bore, the flow passing through the drain hole will be less than 1% of the total measured flow, keeping the measurement error within acceptable limits.

5) BS 6739 Tapping Orientation:

BS 6739 states that the radial location of pressure tapping points on horizontal or inclined pipelines should be based on the type of process fluid. For vertical pipelines, the preferred flow direction is upward for liquids and downward for gases when using metering orifices.

6) ISO/TR 11583 – Wet Gas Application:

ISO/TR 11583 addresses wet gas flow measurement using orifice plates without drain holes. It also notes that there is no established correlation available for flow over-reading caused by drain holes in wet gas service, and such a correlation is generally not considered necessary.

Key Differences Between Drain and Vent Hole

| Feature | Drain Hole | Vent Hole |

|---|---|---|

| Position | Bottom of orifice plate | Top of orifice plate |

| Used For | Gas flow services | Liquid flow services |

| Purpose | Removes trapped liquid | Removes trapped gas |

| Main Risk | Plugging in dirty fluids | Plugging in dirty liquids |

| Alternative | Eccentric orifice (bottom opening) | Eccentric orifice (top opening) |

Frequently Asked Questions (FAQs)

1. What is the main purpose of a drain hole in an orifice plate?

The main purpose of a drain hole is to remove trapped liquid from gas pipelines. It prevents liquid accumulation that can disturb differential pressure measurement and cause flow reading errors.

2. What is the main purpose of a vent hole in an orifice plate?

A vent hole is used to remove trapped gas or air bubbles from liquid pipelines. This ensures accurate pressure drop measurement and stable flow readings.

3. Where is the drain hole located on an orifice plate?

The drain hole is located at the bottom of the orifice plate (6 o’clock position) so that gravity helps drain any trapped liquid easily.

4. Where is the vent hole located on an orifice plate?

The vent hole is located at the top of the orifice plate (12 o’clock position) so that trapped gas bubbles can naturally escape upward.

5. Can a drain hole and vent hole be used together in one orifice plate?

No, both should not be used together in a standard orifice plate.

- Drain hole → for gas service

- Vent hole → for liquid service

6. Do drain and vent holes affect flow measurement accuracy?

Yes, they allow a small amount of unmeasured flow. However, if the hole diameter is less than 10% of the main orifice bore, the measurement error remains below 1%, which is acceptable in most industrial applications.

7. Why are drain holes not recommended for dirty fluids?

In dirty fluids or slurries, the small drain hole can easily get clogged, leading to false readings, maintenance issues, and flow measurement errors.

8. Why are vent holes not recommended for slurry or solid-laden liquids?

Vent holes can also get blocked by solids or sticky material, causing gas entrapment and unstable flow readings.

9. What is the best alternative to drain and vent holes in dirty service?

The best alternative is using an eccentric orifice plate:

- Bottom eccentric for gas with liquid

- Top eccentric for liquid with gas

10. In which industries are drain and vent holes commonly used?

They are widely used in:

- Oil & gas industry

- Power plants

- Water and wastewater treatment

- Chemical processing plants

- Steam and compressed air systems

I hope you like above blog. There is no cost associated in sharing the article in your social media. Thanks for Reading !! Happy Learning