Table of Contents

ToggleIntroduction – Why Pressure Relief Valves Are Critical

Pressure Relief Valves (PRVs) are among the most important safety components used in pressurized systems. Their main job is simple but extremely critical: prevent pressure from rising beyond safe limits.

In industries such as oil & gas, power plants, chemical processing, boilers, compressors, and hydraulic systems, uncontrolled pressure rise can lead to equipment damage, leaks, explosions, or even loss of life. Pressure relief valves act automatically and instantly, making them the last line of defense in any pressure system.

This article explains what pressure relief valves are, how they work, and 7 common types of pressure relief valves, along with their typical applications.

What Is a Pressure Relief Valve?

A pressure relief valve is a self-acting mechanical safety device installed in pressurized systems to protect them from overpressure.

Its basic functions are:

Continuously sense system pressure

Open automatically when pressure exceeds a preset value

Release excess fluid or gas safely

Reseat and close once normal pressure is restored

No electrical power, control signal, or operator intervention is required. This makes pressure relief valves highly reliable, even during emergencies.

How Does a Pressure Relief Valve Work?

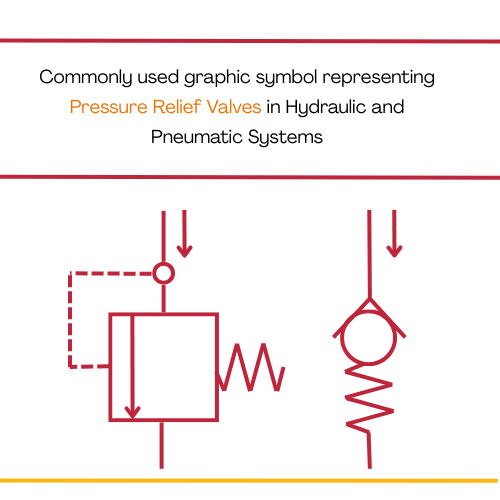

The working principle of a pressure relief valve is based on force balance.

System pressure acts on a disc, piston, or diaphragm

A closing force (spring, pilot pressure, or mechanical element) keeps the valve closed

When pressure force exceeds the closing force, the valve opens

Excess pressure is discharged to a safe outlet

Once pressure drops, the valve closes automatically

Different valve designs use different methods to create the closing force, which results in various types of pressure relief valves.

1. Spring-Loaded Relief Valves

Spring-loaded relief valves are the most commonly used pressure relief valves in industry.

A calibrated spring applies force on the valve disc. When system pressure exceeds the spring force, the disc lifts and releases pressure.

Key characteristics include:

Simple and robust mechanical design

Fast response to pressure rise

No external energy source required

Easy installation and maintenance

Typical applications include:

Steam boilers used in power plants and process industries

Air compressors and compressed air receivers

Pumps operating in closed liquid systems

General industrial pipelines requiring basic overpressure protection

2. Pilot-Operated Relief Valves

Pilot-operated relief valves use system pressure itself to control valve opening.

A small pilot valve senses pressure. When set pressure is reached, the pilot opens and causes the main valve to open fully.

Key characteristics include:

Very high pressure control accuracy

Stable operation at high pressures

Suitable for large flow capacities

Minimal pressure loss during normal operation

Typical applications include:

High-pressure gas transmission pipelines

Oil and gas production facilities

Refineries and petrochemical plants

Power plants requiring precise pressure regulation

3. Temperature-Activated Relief Valves

Temperature-activated relief valves protect systems against thermal expansion-induced pressure rise.

In liquid systems, temperature increase can cause extreme pressure buildup even when there is no flow. These valves release pressure before damage occurs.

Key characteristics include:

Protection against thermal expansion

Operation linked to temperature-induced pressure rise

Compact and simple construction

Typical applications include:

Blocked-in liquid pipelines exposed to heat

Heat exchangers with thermal expansion risk

Storage tanks carrying temperature-sensitive fluids

Hot oil circulation systems

4. Balanced Bellows Relief Valves

Balanced bellows relief valves are designed to eliminate the influence of back pressure.

A metallic bellows isolates the spring chamber from downstream pressure, keeping the set pressure stable.

Key characteristics include:

Consistent set pressure performance

Resistance to variable back pressure

Suitable for closed discharge systems

Typical applications include:

Chemical processing plants handling corrosive fluids

Systems with fluctuating or constant back pressure

Closed vent or flare systems

Toxic or hazardous fluid services

5. Nozzle Type Relief Valves

Nozzle type relief valves are optimized for high-capacity and fast-acting pressure relief.

Their design allows a sharp and rapid opening once the set pressure is reached.

Key characteristics include:

Very fast lift action

High discharge capacity

Reliable reseating after pressure normalization

Typical applications include:

High-pressure steam boilers

Superheated steam pipelines

Steam distribution headers

Power generation systems

6. Piston-Type Relief Valves

Piston-type relief valves use a sliding piston to sense pressure and control opening.

They are mechanically strong and suitable for demanding industrial environments.

Key characteristics include:

High mechanical strength

Suitable for high-pressure applications

Longer service life in harsh conditions

Typical applications include:

Hydraulic power units

High-pressure oil circuits

Industrial machinery operating at elevated pressures

Systems handling dirty or viscous fluids

7. Diaphragm-Type Relief Valves

Diaphragm-type relief valves use a flexible diaphragm as the pressure-sensing and sealing element.

They are highly sensitive and provide excellent sealing performance.

Key characteristics include:

Leak-tight shutoff

High sensitivity at low pressures

Good compatibility with corrosive media

Typical applications include:

Chemical dosing and metering systems

Low-pressure gas distribution lines

Corrosive fluid services

Applications requiring tight sealing rather than high flow

Key Factors to Consider When Selecting a Pressure Relief Valve

Before selecting a pressure relief valve, always evaluate:

Maximum allowable working pressure

Type of fluid (gas, steam, liquid)

Operating temperature range

Required relieving capacity

Presence of back pressure

Applicable industry standards and codes

Incorrect valve selection can lead to frequent lifting, leakage, or failure to protect the system.

Pressure relief valves may appear simple, but their role in industrial safety is critical and non-negotiable.

Understanding the different types of pressure relief valves and their working principles helps engineers, technicians, and students make safer design and maintenance decisions.

From small compressors to massive refinery pipelines, a properly selected pressure relief valve can prevent accidents, downtime, and catastrophic failures.

I hope you like above blog. There is no cost associated in sharing the article in your social media. Thanks for Reading !! Happy Learning