Table of Contents

ToggleTemperature Classes - Introduction

In hazardous areas, it is not just sparks or electrical faults that can cause explosions. Sometimes, heat alone is enough to ignite flammable gases, vapors, or dust. That is why temperature classes are so important in hazardous area instrumentation.

If equipment gets too hot, it can become the ignition source. Temperature classes are used to make sure the surface temperature of a device never exceeds the ignition temperature of the hazardous substance around it.

Let us explore what these temperature classes mean, why T4 and T6 matter so much, and what can go wrong if a device exceeds its approved temperature rating.

What Are Temperature Classes?

Temperature classes define the maximum surface temperature that a device can reach during operation. These are especially important in hazardous areas where flammable materials might be present in the air.

Each flammable gas or vapor has an auto-ignition temperature – the lowest temperature at which it can catch fire without any spark or flame. The equipment in that area must have a surface temperature lower than that.

Common Temperature Classes (Simplified Table)

| Temperature Class | Max Surface Temp | Example Gases |

|---|---|---|

| T1 | 450°C | Hydrogen, methane |

| T2 | 300°C | Ethylene |

| T3 | 200°C | Kerosene, gasoline |

| T4 | 135°C | Acetone, ammonia, most solvents |

| T5 | 100°C | Some chemical vapors |

| T6 | 85°C | Carbon disulfide, highly sensitive gases |

Why T4 and T6 Matter Most

Most industrial hazardous areas involve gases or vapors that fall into the T4 or T6 category. That means most equipment must stay below 135°C (T4) or even below 85°C (T6).

Why is this critical?

- A transmitter rated T4 is not safe in a T6 zone.

- If the equipment exceeds the allowed temperature, it can ignite the gas around it — even without a spark.

- T6 zones are often found in chemical plants or labs where highly flammable substances are used.

What Happens If You Exceed the Temperature Class?

If a device gets hotter than its certified class:

- It can become an ignition source.

- Auto-ignition may happen silently, leading to fires or explosions.

- Nearby combustible gases or vapors can ignite on contact with the hot surface.

Even if the explosion doesn’t happen right away, safety is compromised, and the device is no longer compliant with ATEX or IECEx certification.

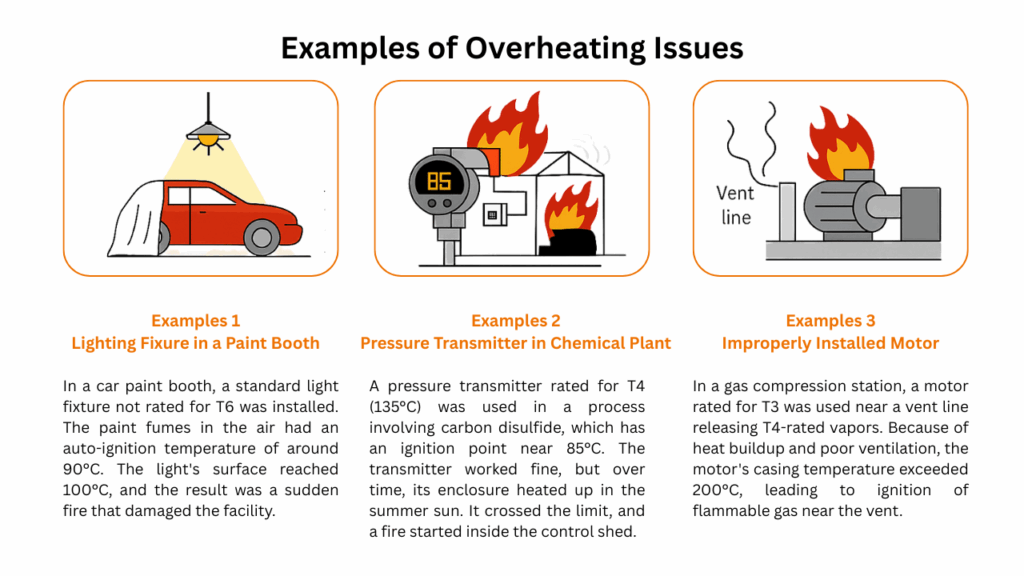

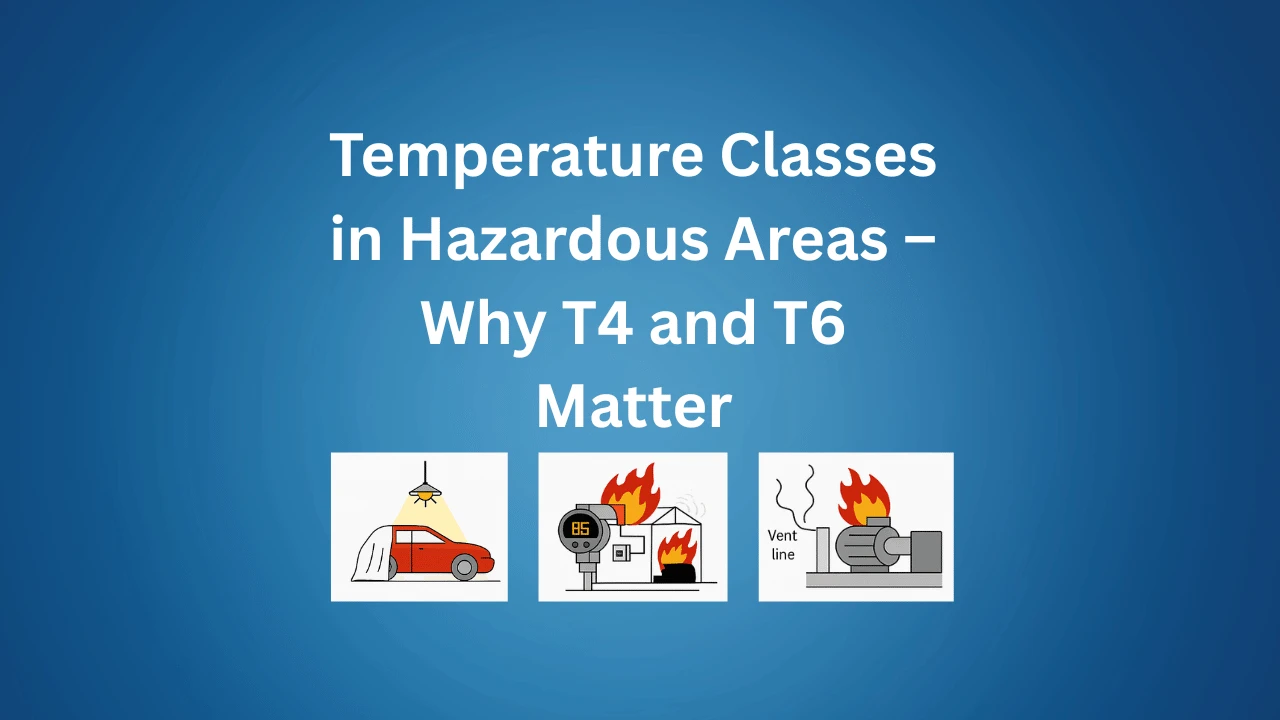

Examples of Overheating Issues

These incidents show why it’s so important to:

- Understand the temperature classification of your environment

- Always choose equipment with a T-rating equal to or lower than the auto-ignition temperature of the materials present

Tips for Selecting Equipment Based on Temperature Class

- Know your hazardous substance: Check the Material Safety Data Sheet (MSDS) for ignition temperatures.

- Check ambient conditions: Consider direct sunlight, poor ventilation, or nearby heat sources.

- Review certification markings: Look for labels like Ex d T4 or Ex ia T6.

- Allow for margin: Choose a T-rating below the ignition temperature for added safety.

- Inspect regularly: Dust buildup or poor installation can cause overheating.

Summary

Temperature classes are a critical part of explosion protection. While many focus on electrical safety, heat alone can be just as dangerous in hazardous areas.

Choosing the right T-class (especially T4 or T6) can make the difference between a safe process and a serious accident. Never assume the device is safe just because it’s ATEX or IECEx certified. You must also check the temperature class matches your process conditions.

Always ask: “How hot does this device get, and is that safe for the environment it’s in?”

I hope you like above blog. There is no cost associated in sharing the article in your social media. Thanks for reading!! Happy Learning!!

1 Comment