Table of Contents

TogglePaddle Type Level Switch : Introduction

Paddle Type Level Switch is a device used for level detection of powder, grains, or bulk materials in silos, hoppers, and bins.

It works by rotating a small paddle inside the container and when the material touches it, the paddle stops and sends a signal. This simple action helps industries avoid overflow, spillage, and downtime.

Imagine an industrial grain silo. Day after day, grains pour in from the top. Deep inside the silo, there is a small paddle slowly turning.

It looks like nothing special, just quietly rotating. But the moment the grains touch it, the paddle suddenly stops. And with that tiny stop, a signal is sent to stop filling the silo.

That’s it. Simple. Silent. Reliable.

This is nothing but a Paddle Type Level Switch.

What Is Paddle Type Level Switch?

Think of it as a guard standing inside a tank or bin.

- If no material is there, the guard keeps waving his hand (the paddle keeps rotating).

- But the moment the material comes and touches it, the hand can’t move anymore.

- The guard immediately raises an alarm — “The tank is full here!”

“A paddle type level switch tells us whether the level of powder, grain, sand or sugar has reached a certain point inside a container.”

How Does It Really Work?

Let us see below the paddle’s daily life routine:

- Free to turn: The paddle rotates slowly with the help of a small motor. Nothing is touching it, so it moves happily.

- Material arrives: The level rises and the material begins to surround the paddle.

- The stop moment: The grains or powder push against the paddle. It can’t move anymore.

- The signal: A tiny switch inside the device changes position and sends an electrical signal to the control panel.

- Back to normal: When the level drops, the paddle is free again. It starts rotating once more, waiting for the next cycle.

So, the story is Rotate → Stop → Signal.

Where Do We Use Paddle Type Level Switch?

This Paddle Type Level Switch has many applications:

- Grain silos – to know when the silo is full.

- Cement bins – to prevent overflow.

- Sugar factories – to alert when the hopper is empty.

- Plastic industry – to check powder or granule levels.

- Food packaging – for flour, rice, coffee powder, or spices.

In all these places, the paddle does not measure “how much” is inside.

It only tells “yes, the material is here” or “no, it’s not.” And often, that’s all we need.

Why Do People Like Paddle Type Level Switch?

- It is simple. No complicated electronics, just a paddle and motor.

- It is tough. Works even in dusty, rough environments.

- It is clear. Either the paddle is turning or it’s not.

- It is cheap compared to fancy level instruments.

That is why many industries still trust it, even when radar and ultrasonic sensors exist.

Sometimes, simple works best.

Limitations of Paddle Type Level Switch

Of course, every hero has its limits. The paddle too:

- It doesn’t work well with sticky or wet materials. The paddle may get stuck.

- It gives only a point signal, not continuous level measurement.

- The torque setting (the force needed to stop the paddle) must match the material density. Otherwise, it may give wrong alarms.

- If used in explosive areas, we must use a special safe version.

So, it is reliable but only if used correctly.

Let us take an example

Imagine this:

In a flour mill, workers are filling a tall bin with wheat flour. They cannot see inside because of dust and height. If the bin overflows, it will waste hours of cleanup. But a small paddle type switch is installed at the top. The moment flour touches it, the paddle stops, the alarm rings, and the filling is cut off.

No shouting, no accidents, no spillage.

Just one small paddle doing its job silently.

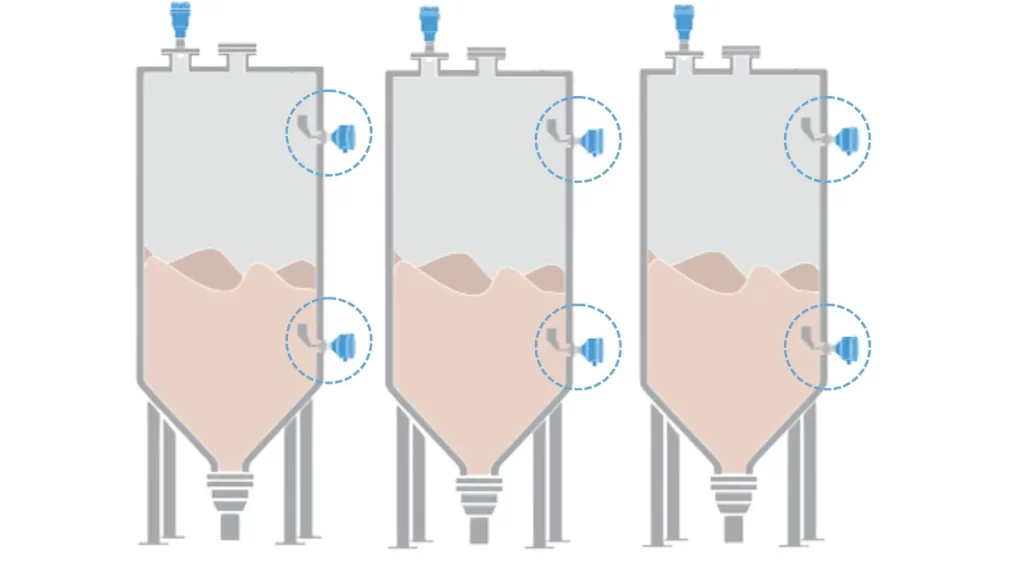

What Should You Check Before Choosing Paddle Type Level Switch?

When engineers buy or install a paddle type level switch, they usually ask:

- What is the density of the material? (Is it light like plastic pellets or heavy like cement?)

- Will the material flow freely or does it form lumps?

- Where should we mount the paddle — top, middle, or bottom?

- Is the area dusty or explosive? (Need special approvals.)

- What is the temperature and pressure inside the tank?

By answering these questions, you make sure the little paddle can do its duty without trouble.

What we learn today?

In industrial level measurement, the Paddle Type Level Switch may look old-fashioned compared to new radar and laser sensors.

But ask anyone in a cement plant or sugar mill, they will tell you this simple device is still their best friend.

It is like a silent watchman. He doesn’t tell you how crowded the hall is, but he firmly says when the hall is full. And sometimes, that’s all you really need.

So next time you pass a silo or a hopper, just smile. Somewhere inside, a little paddle may be quietly turning, waiting for its moment to say:

“Stop. The level is here.”

Web Stories

I hope you like above blog. There is no cost associated in sharing the article in your social media. Thanks for reading!! Happy Learning!!