Magnetic proximity sensors are electronic devices used to detect the presence, movement, or position of objects without physical contact. These sensors work by sensing magnetic fields, either from a permanent magnet or from changes in the surrounding magnetic environment. They are widely used in industrial automation, robotics, safety systems, automotive applications, and more.

Because magnetic proximity sensors do not require physical contact, they are ideal for harsh or dirty environments where mechanical switches may fail.

In this article, I will explain the basic working principle, different types, specifications, benefits, and common applications of magnetic proximity sensors. Let’s Start !!

Table of Contents

ToggleMagnetic Proximity Sensor Characteristics

These properties make magnetic proximity sensors suitable for use in environments where mechanical or optical sensors may not perform reliably.

Magnetic Proximity Sensor Specifications

When selecting a magnetic proximity sensor, consider the following specifications:

- Sensing Range: The maximum distance at which the sensor can detect the magnet.

- Switching Frequency: How fast the sensor can switch between on and off states.

- Output Type: Sensors can have digital (ON/OFF) or analog outputs.

- Operating Voltage: Typical values are 5V, 12V, or 24V DC.

- Temperature Range: The environmental temperature the sensor can handle.

- Housing Material: Plastic or metal depending on the application.

- Mounting Style: Flush or non-flush, depending on how the sensor is installed.

Types of Magnetic Proximity Sensors

There are several types of magnetic proximity sensors, each with its own working principle and use case.

A. Reed Switch

A reed switch consists of two thin metal strips (called reeds) sealed inside a glass tube. When a magnet comes close, the magnetic field causes the reeds to come together and close the circuit.

- Working Principle: Magnetic field pulls the reeds together to make contact.

- Use Case: Door sensors, home security systems, and position sensing.

- Advantage: Simple and inexpensive.

B. Magnetostrictive Sensor

Magnetostrictive sensors use a wave-propagation method where a magnetic field interacts with a specially designed wire. The position of the magnetic field is determined based on the time taken for a signal to travel.

- Working Principle: Measures time delay between electric pulse and returned signal caused by magnetic interaction.

- Use Case: Industrial position measurement (e.g., hydraulic cylinders).

- Advantage: Very accurate and high resolution.

C. Magneto-Resistive Sensor

These sensors use materials that change their electrical resistance when exposed to a magnetic field.

- Working Principle: Resistance of the sensor material changes with magnetic field strength.

- Use Case: Automotive speed sensors, gear tooth detection.

- Advantage: Sensitive to weak magnetic fields and works in low-power systems.

D. Inductive Magnetic Proximity Sensor

Inductive sensors detect metal objects but can be adapted to work with magnets using specific circuitry.

- Working Principle: Induces eddy currents in nearby metallic objects.

- Use Case: Detecting magnetic metals.

- Advantage: Good for rough and dirty environments.

E. Hall Effect Sensor

This is one of the most common magnetic sensors. It uses the Hall effect—when a magnetic field is applied perpendicular to an electric current in a conductor, it produces a voltage.

- Working Principle: Generates voltage proportional to the magnetic field.

- Use Case: Automotive crankshaft position sensors, brushless motors.

- Advantage: Robust and suitable for high-speed applications.

F. Linear Variable Differential Transducer (LVDT) with Magnetic Core

Though not always classified strictly as a magnetic sensor, LVDTs often use a magnetic core and coil system to detect linear displacement.

- Working Principle: Movement of the magnetic core changes the voltage output.

- Use Case: Industrial automation for measuring linear position.

- Advantage: High accuracy and repeatability.

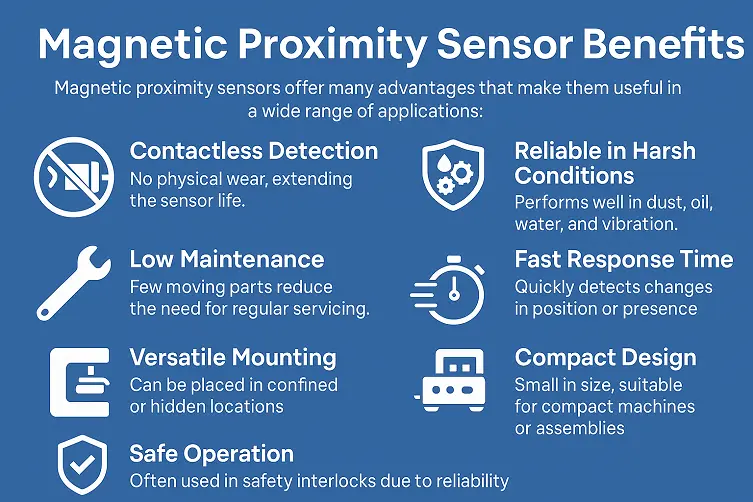

Magnetic Proximity Sensor Benefits

Magnetic proximity sensors offer many advantages that make them useful in a wide range of applications:

Magnetic Proximity Sensor Applications

These sensors are found in many industries and devices. Here are some common examples:

- Automotive Industry: Used for speed sensing, gear position detection, and crankshaft/camshaft position monitoring.

- Industrial Automation: Detecting parts in assembly lines, controlling robotic arms, and positioning systems.

- Security Systems: Door and window open/close detection in home or office security setups.

- Consumer Electronics: Used in smartphones and laptops to detect screen closures.

- Medical Equipment: Used in devices that require safe, contactless motion sensing.

- Elevators and Doors: Detects if doors are fully closed or open.

- Railways and Transportation: Position sensing of moving parts and safety mechanisms.

Summary

Magnetic proximity sensors are powerful tools in modern sensing and automation applications. With various types available—like reed switches, Hall effect sensors, and magneto-resistive sensors—they offer solutions for a wide range of industries.

Their ability to detect motion or presence without physical contact, even in harsh environments, makes them highly reliable and valuable.

Whether you are a student learning about sensors for the first time or a beginner in electronics and instrumentation, understanding the basics of magnetic proximity sensors gives you a solid foundation for exploring more complex systems in automation and control.

I hope you like above blog. There is no cost associated in sharing the article in your social media. Thanks for reading!! Happy Learning!!