When working in hazardous areas, safety is the top priority. Industries like oil & gas, chemicals, mining, and pharmaceuticals often deal with environments where flammable gases, vapors, or dust are present. In such places, even a small electrical spark can lead to an explosion.

To avoid this risk, instruments used in these areas must meet strict safety standards. Two common protection methods are Explosion-Proof and Intrinsically Safe (IS) designs. While both aim to prevent explosions, they work in very different ways. This article explains their differences, use cases, certifications, and where each is best suited – in simple, easy-to-understand language.

Table of Contents

ToggleWhat Does "Hazardous Area" Mean?

A hazardous area is a location where flammable gases, vapors, or dust are likely to be present in enough quantity to cause an explosion.

Examples:

- Inside or near oil refineries

- Chemical processing plants

- Fuel storage terminals

- Paint shops and spray booths

- Grain silos or flour mills (dust hazard)

To protect life and property, special equipment must be used that doesn’t trigger ignition under these risky conditions.

What is Explosion-Proof Protection?

Explosion-proof instruments are designed to contain an explosion inside the device, so it doesn’t ignite the surrounding hazardous atmosphere.

How it works:

- The instrument is housed in a strong metal enclosure.

- If an explosion occurs inside the enclosure (due to a spark or fault), the enclosure contains the blast.

- Hot gases escaping from the enclosure are cooled down by traveling through flame paths, so they don’t ignite the outside atmosphere.

Key Points:

- Built to withstand internal explosions.

- Heavier and bulkier due to thick walls.

- Common in Zone 1 (where explosive atmosphere is likely during normal operation).

- Requires special glands and certified conduit systems for wiring.

Example Devices:

- Pressure transmitters in oil refineries

- Flameproof junction boxes

- Motors and lighting in classified zones

What is Intrinsically Safe Protection?

Intrinsically safe (IS) instruments work on a completely different principle: they prevent sparks or heat from happening in the first place.

How it works:

- The energy in the circuit is limited to a level that cannot cause ignition, even during a fault.

- This is done using safety barriers, Zener diodes, and current-limiting resistors.

- These barriers are usually located in the safe (non-hazardous) area.

Key Points:

- Prevents ignition by limiting energy.

- Safe even if a fault occurs (e.g., wire break or short circuit).

- Devices are lighter and smaller.

- Suitable for Zone 0 (where hazardous gas is present continuously or for long periods).

- Easier to maintain, modify, or replace without shutting down power.

Example Devices:

- Temperature and pressure transmitters

- Flow meters with 4-20 mA output

- Handheld gas detectors

- Data loggers and signal conditioners

How Does Intrinsic Safety Equipment Work?

To prevent ignition in hazardous areas, it’s important to keep both the power and the temperature of the instrument as low as possible. While the exact power limits can be complex, in simple terms, it usually means using less than 29 volts and under 300 milliamps. Another easy rule is to keep the total power below 1.3 watts.

Many instruments run on 24V and can be designed to use less than 500 mA, which often meets the safety requirements for intrinsically safe (IS) systems.

There are also six temperature classes, and most IS equipment falls into the T4 category, which means it will not get hotter than 135°C (275°F). Devices using less than 1.3 watts usually stay under this temperature.

In most cases, you’ll need to send a signal into or out of the hazardous area. Any device installed inside the hazardous zone must be approved for use in an IS system.

To protect the system, special safety barriers are used—these must be installed outside the hazardous area, in a safe (non-hazardous) location, where no flammable gases or dust are present.

ATEX and IECEx Certifications

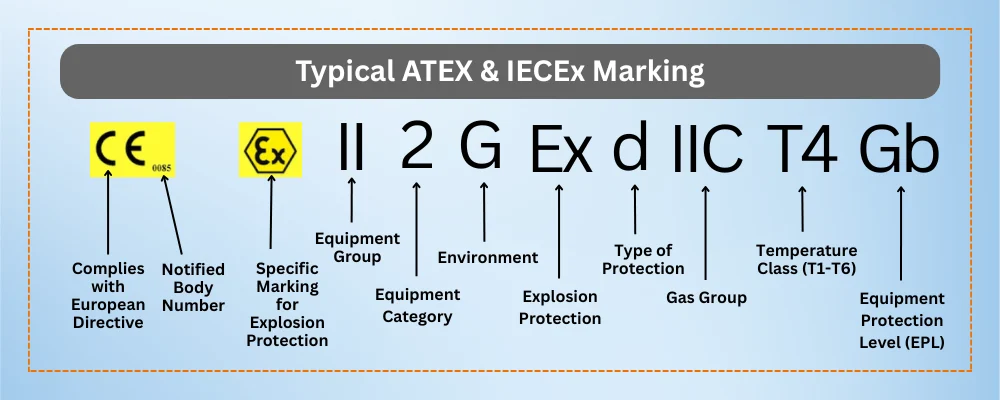

To ensure global safety and compliance, equipment is certified by official bodies under standards like ATEX (Europe) and IECEx (International).

ATEX:

- European directive for equipment used in explosive atmospheres.

- Two main directives:

- ATEX 114 (2014/34/EU): For manufacturers

- ATEX 153 (1999/92/EC): For end-users (how to safely use equipment)

IECEx:

- International Electrotechnical Commission’s system for certification.

- Used widely in countries outside Europe (e.g., Australia, Middle East, Asia).

- Similar requirements as ATEX but broader acceptance.

Both ATEX and IECEx label devices with:

- Equipment Group (I for mines, II for surface industry)

- Category or Zone suitability (0, 1, 2)

Type of protection (Ex d = Explosion-Proof, Ex i = Intrinsically Safe)

Zone Classifications Explained

Hazardous areas are divided into zones based on the likelihood and duration of explosive atmosphere presence.

For Gases/Vapors:

- Zone 0: Explosive gas present continuously or for long periods.

- Zone 1: Gas present occasionally during normal operation.

- Zone 2: Gas present only in abnormal conditions.

For Dust:

- Zone 20: Combustible dust present continuously.

- Zone 21: Dust present occasionally.

- Zone 22: Dust present only in abnormal situations.

Intrinsically Safe = Ideal for Zone 0

Explosion-Proof = Commonly used in Zone 1 and 2

Comparison between Explosion-Proof (Ex d) and Intrinsically Safe (Ex i)

Feature | Explosion-Proof (Ex d) | Intrinsically Safe (Ex i) |

Protection Principle | Contains explosion | Prevents ignition |

Enclosure | Heavy, thick-walled metal | Slim, compact design |

Wiring Requirements | Conduit, flameproof glands | Barriers, standard cabling |

Zone Suitability | Zone 1, Zone 2 | Zone 0, Zone 1, Zone 2 |

Maintenance | Needs shutdown to service | Can be serviced live |

Typical Use | Motors, junction boxes | Transmitters, sensors |

Cost | Higher installation cost | Lower wiring cost |

Which One Should You Use?

The choice between explosion-proof and intrinsically safe depends on:

- Zone classification of the area (Zone 0 requires IS)

- Type of device (e.g., motor vs. transmitter)

- Ease of maintenance

- Size and weight limitations

- Project budget (IS is usually cheaper to install)

Modern Trends in Hazardous Area Instrumentation

- Many manufacturers now design dual-certified instruments (both Ex d and Ex i).

- Smart transmitters and sensors include self-diagnostics and fail-safe alerts.

- Explosion-proof enclosures are available with modular components and better thermal management.

- Barriers and isolators are now more compact, DIN-rail mountable, and easier to wire.

- More companies are shifting to intrinsically safe wireless transmitters for remote data collection.

Conclusion

Explosion-proof and intrinsically safe protection methods both play an important role in keeping hazardous areas safe. Understanding how each one works helps you select the right device for the right zone.

- Use Explosion-Proof when you’re dealing with higher-energy equipment or Zone 1 motors.

- Use Intrinsically Safe for sensors, transmitters, and Zone 0 or handheld devices.

Always check the latest ATEX or IECEx certifications, and make sure your installation follows the right safety codes.

By choosing the right protection method, you’re not just complying with regulations—you’re protecting your people, your process, and your plant.

I hope you like above blog. There is no cost associated in sharing the article in your social media. Thanks for reading!! Happy Learning!!