Table of Contents

ToggleWhat is difference between ATEX and IECEx?

When gases, vapors or dust that can burn get mixed with air in the right amount, they can form an explosive atmosphere. If any spark or heat source appears in this situation, an explosion can happen.

Explosions can cause serious injuries, loss of life and major damage to equipment and buildings. They can also create long-term financial and environmental problems.

That is why it is extremely important to take the right steps to control explosive atmospheres and make sure that no ignition source is present.

To help industries stay safe and aware of these risks, different safety rules, standards, and guidelines have been created. These ensure that both manufacturers and operators follow the best safety practices.

Two major systems used globally to prove equipment safety in hazardous areas are the ATEX directive and the IECEx scheme.

They help manufacturers show that their equipment meets the required safety levels to prevent explosions.

What is the difference between ATEX and IECEx certification?

Even though both ATEX and IECEx follow the same international IEC 60079 standards, there are some important differences.

ATEX is mainly used in the European Union and is a key part of identifying and classifying hazardous areas there.

IECEx is a global certification system that is completely based on international standards and can be used in countries all around the world.

Because of this, many industries often compare ATEX and IECEx to decide which certification is right for their equipment and applications.

Please refer IECEx Informative Guide here.

What is the ATEX Certification?

The term ATEX comes from the French words “ATmosphères EXplosibles,” which refers to equipment that is designed to be used in places where explosive atmospheres may occur.

ATEX certification is mandatory in Europe, and it covers everything from how the equipment is made to how it is installed and used in hazardous areas.

ATEX rules are divided into two main directives:

A. Directive 1999/92/EC – The ATEX “User” Directive

This directive focuses on workers’ safety in areas where explosions could happen. It requires companies to:

1) Do a complete assessment of explosion risks

2) Classify hazardous areas into different Zones and label their entry points

3) Ensure safe working conditions

4) Properly guide visitors and subcontractors

5) Choose safe and suitable equipment for explosive environments

B) Directive 2014/34/EU – The ATEX “Equipment” Directive

This part is meant for manufacturers. It sets rules for any equipment that may be used in explosive atmospheres on the surface, underground, or on offshore installations.

This directive includes:

1) Any equipment that might create an ignition source and cause an explosion

2) Protective systems used to prevent or reduce explosion risks

Manufacturers must ensure their products meet strict health and safety requirements.

For higher-risk categories, the equipment must be assessed and certified by a Notified Body.

For some lower-risk categories (for example Category 3 equipment), ATEX allows manufacturer self-declaration with a technical file kept for inspection.

What is ATEX Marking?

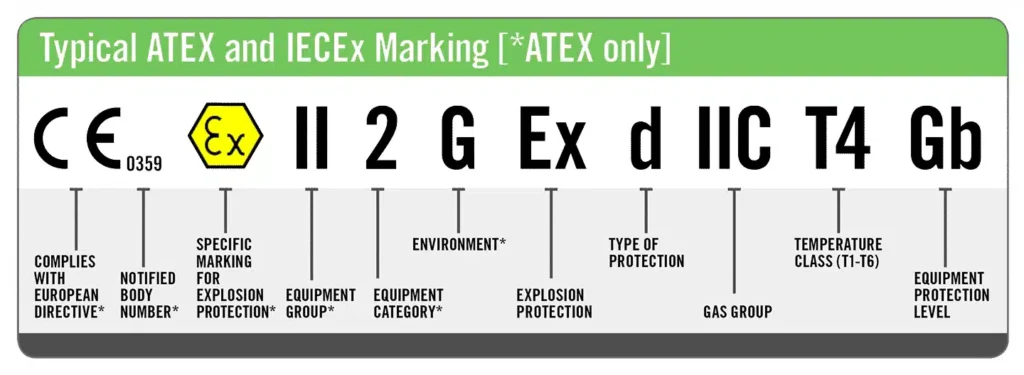

Equipment compliant with ATEX is marked with the CE mark and the “Ex” symbol. The full marking line also includes information such as:

- Equipment group and category / EPL

- Type of protection (Ex d, Ex e, Ex i, etc.)

- Temperature class and gas/dust group

- Notified Body number (if a Notified Body was involved)

ATEX certification is mainly used in the European Union and also in the four EFTA countries Iceland, Liechtenstein, Norway, and Switzerland

What is IECEx Certification?

The IECEx system (International Electrotechnical Commission for Explosive Atmospheres) is recognized globally and is used in many countries outside the EU.

What IECEx Does?

IECEx is an international certification scheme that requires equipment to fully meet IEC safety standards.

Special IECEx-approved testing labs check products designed for use in explosive atmospheres. If the product meets all safety requirements, an IECEx Certificate of Conformity is issued.

Why IECEx Certification Matters?

An IECEx certificate:

1) Gives direct access to many global markets

2) Shows that the equipment follows international safety standards

3) Supports local certification processes in different countries

ATEX vs IECEx: Technical Similarities

The technical rules and safety standards used in both ATEX and IECEx are almost the same.

Because of this, many manufacturers now choose to have their products certified under both ATEX and IECEx, making them suitable for use in both Europe and the rest of the world.

ATEX vs IECEx: Understanding Certification Levels

Both ATEX and IECEx use the same IEC 60079 standards, so the terminology used to show the “level of protection” is common in both systems. There are three concepts to understand:

1. Equipment Categories (ATEX – Legal Requirement)

Under ATEX 2014/34/EU, equipment is placed into legal categories based on risk level:

Gas (G):

- Category 1G → Suitable for Zone 0

- Category 2G → Suitable for Zone 1

- Category 3G → Suitable for Zone 2

Dust (D):

- Category 1D → Suitable for Zone 20

- Category 2D → Suitable for Zone 21

- Category 3D → Suitable for Zone 22

Categories are unique to ATEX.

They are required for CE marking.

2. Equipment Protection Levels (EPL) – Used in ATEX and IECEx

EPLs come from IEC standards and are used by both systems:

For Gas:

- Ga – Very high protection (Zone 0)

- Gb – High protection (Zone 1)

- Gc – Enhanced protection (Zone 2)

For Dust:

- Da – Very high protection (Zone 20)

- Db – High protection (Zone 21)

- Dc – Enhanced protection (Zone 22)

Mining:

- Ma, Mb – High/Very high protection for mining

EPLs are not ATEX-only and not IECEx-only.

They are simply part of the IEC standards used by both systems.

3. Types of Protection (Ex d, Ex e, Ex i, Ex t…) Used in Both ATEX & IECEx

These codes describe how ignition is prevented:

- Ex d – Flameproof

- Ex e – Increased Safety

- Ex i (ia / ib / ic) – Intrinsic Safety

- Ex t (ta / tb / tc) – Dust-protected enclosures

- Ex m (ma / mb / mc) – Encapsulation

- Ex p, Ex q, etc.

These are not IECEx levels but they are standard IEC 60079 protection methods.

They appear on both ATEX and IECEx marking labels.

ATEX uses legal Equipment Categories, while both ATEX and IECEx use the same IEC-based Equipment Protection Levels (EPLs) and the same types of protection such as Ex d, Ex e, Ex i, Ex t, etc.

The protection codes (Ex ia, Ex db, Ex ta) are not IECEx levels, they are IEC protection methods used in both systems.

Understanding Zones

Both ATEX and IECEx classify hazardous areas into zones, depending on how often and how long an explosive atmosphere (gas, vapor, or dust) is likely to be present.

For gases and vapors, the zone numbers are almost the same in both systems.

For dusts, the zones are also similar, but there are small differences between ATEX and IECEx.

Please refer table below.

Gases or Vapors

| Zone | ATEX | IECEx |

|---|---|---|

| 0 | A place where an explosive atmosphere is present all the time | An explosive atmosphere is present continuously or for long periods |

| 1 | A place where an explosive atmosphere may appear from time to time | An explosive atmosphere is likely during normal operation |

| 2 | A place where an explosive atmosphere is unlikely, and if it does happen, it is brief | An explosive atmosphere is not expected in normal operation, but if it occurs, it will be short-lasting |

Dust

| Zone | ATEX | IECEx |

|---|---|---|

| 20 | A place where an explosive dust atmosphere is present all the time | Explosive dust atmosphere is present continuously or for long periods |

| 21 | A place where an explosive dust atmosphere may occur occasionally | Explosive dust atmosphere is likely in normal operation |

| 22 | A place where an explosive dust atmosphere is unlikely, and if present, it is short | Explosive dust atmosphere is not likely in normal use, but if it happens, it will be brief |

For Modern electrical equipment, ATEX and IECEx use the same IEC 60079 standards, so the technical safety requirements are almost identical.

The main differences are in the legal framework (EU law vs voluntary scheme), allowed conformity routes (self-declaration vs mandatory third-party certification) and the way the equipment is marked and documented, not in the basic safety level.

What we learn today?

ATEX, IECEx, and similar standards are essential for keeping people and equipment safe in explosive environments.

By understanding the rules, regional differences, and certification levels, companies can choose the right protection and stay compliant.

Following both ATEX and IECEx not only improves safety but also helps manufacturers access global markets and ensures their equipment works safely across different regions.

I hope you like above blog. There is no cost associated in sharing the article in your social media. Thanks for Reading !! Happy Learning

1 Comment