Table of Contents

ToggleProgrammable Logic Controllers (PLCs) act as the brain of machines and processes. From controlling motors on a conveyor belt to monitoring temperatures inside a chemical reactor, PLCs handle thousands of tasks every second.

But a PLC alone cannot do everything. It must continuously talk with sensors, actuators, drives, HMIs, and SCADA systems.

This communication is made possible by industrial communication protocols.

A communication protocol is simply a set of rules that allows devices to exchange data correctly and reliably. Without the right protocol, even the best PLC system would fail to function smoothly.

Different industries use different protocols based on speed, distance, reliability, cost, and system architecture.

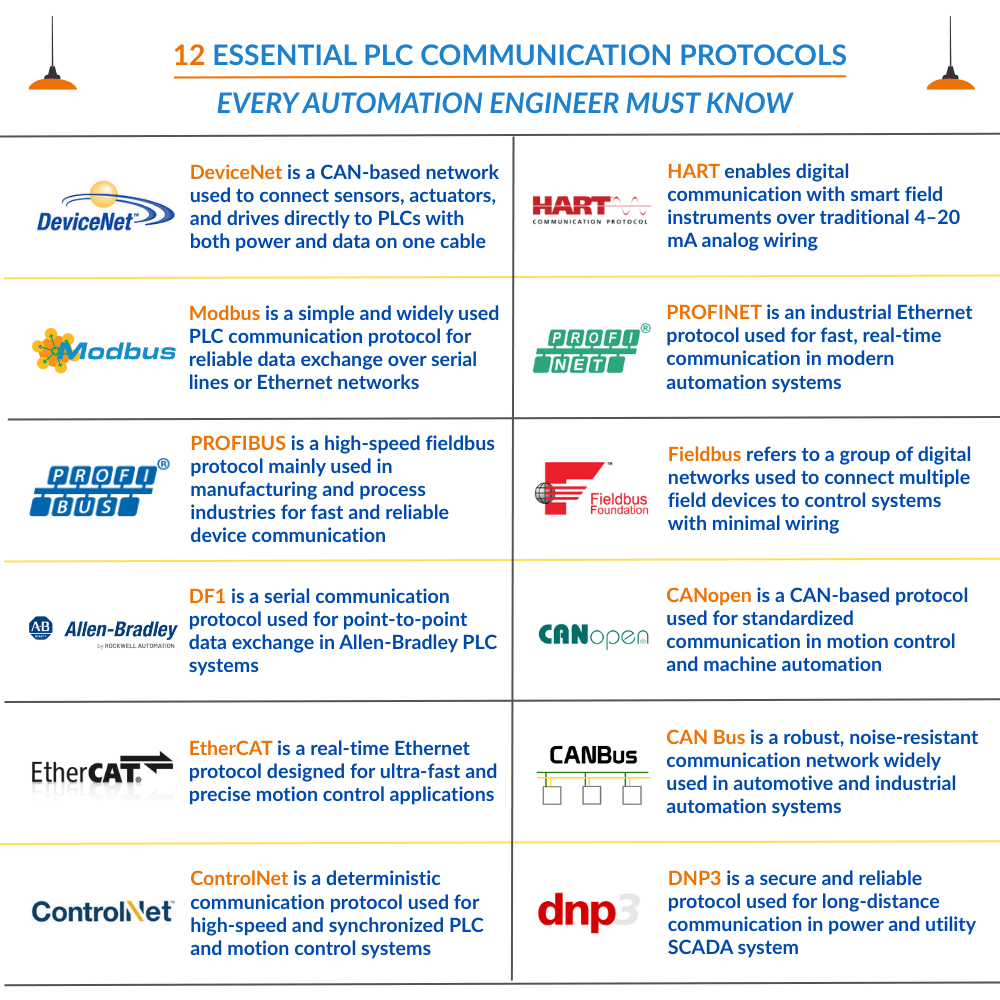

In this article, we will clearly understand 12 important communication protocols used in PLC systems, their working concepts, and where they are commonly applied.

So lets start!

Understanding the Role of Communication Protocols in PLCs

A PLC needs information from field devices such as pressure sensors, flow meters, level transmitters, valves, and motors. It also needs to send commands back to these devices. Communication protocols define how this data is formatted, transmitted, received, and checked for errors.

Good communication ensures fast response, accurate data transfer, system synchronization, and high reliability. Poor communication leads to delays, data loss, system faults, and unsafe operations.

1. DeviceNet Protocol

DeviceNet was developed by Allen-Bradley, which is now part of Rockwell Automation. It is based on CAN (Controller Area Network) bus technology and is mainly used for connecting sensors, actuators, and motor drives to a PLC.

One of the biggest advantages of DeviceNet is that it allows both power and communication on the same cable, which reduces wiring cost and installation time. It is known for its rugged design, making it suitable for harsh industrial environments. DeviceNet is widely used in automobile manufacturing, packaging machines, and assembly lines.

It offers good diagnostics and reliable data exchange, but its speed and distance are limited compared to modern Ethernet-based protocols.

2. Modbus Protocol

Modbus is one of the oldest and most widely used industrial communication protocols in the world. Because of its simplicity and open nature, it is supported by almost all PLC brands and industrial devices.

Modbus works mainly in two forms. Modbus RTU uses serial communication such as RS-232 or RS-485. Modbus TCP/IP works over Ethernet networks. Due to this flexibility, Modbus is found in industries like water treatment plants, building automation systems, power monitoring systems, and process control plants.

Students prefer learning Modbus first because it is easy to understand. It follows a master–slave concept where the PLC acts as the master and the field devices act as slaves. Even today, Modbus remains popular because of its low cost and wide compatibility.

3. PROFIBUS Protocol

PROFIBUS stands for Process Field Bus and was developed mainly by Siemens along with other automation companies. It is one of the most successful fieldbus systems in industrial automation.

PROFIBUS has two major versions. PROFIBUS DP is used for fast communication with field devices like sensors and drives. PROFIBUS PA is used in process industries where intrinsic safety and long cable distances are required, such as chemical and oil & gas plants.

This protocol is commonly found in automotive industries, food and beverage production, pharmaceutical plants, and chemical processing units. PROFIBUS offers high speed, good reliability, and strong global support.

4. DF1 Protocol

DF1 is a proprietary serial communication protocol developed by Rockwell Automation for Allen-Bradley PLCs. It is mainly used for point-to-point communication between PLCs, HMIs, and programming computers.

It is mostly found in small and medium-sized PLC systems, especially in older installations. DF1 is easy to configure and reliable for short distances. However, because it is a serial protocol and not Ethernet-based, it is gradually being replaced by modern networks like EtherNet/IP.

Still, many industries continue to use DF1 due to legacy systems and stable performance.

5. EtherCAT Protocol

EtherCAT stands for Ethernet for Control Automation Technology. It is a high-speed, real-time Ethernet protocol specially designed for motion control and fast automation systems.

EtherCAT allows data to be processed “on the fly” as it passes through each device. This makes communication extremely fast and precise. It is widely used in robotics, CNC machines, packaging lines, printing machines, and semiconductor manufacturing.

For students, EtherCAT is important to understand because it represents the modern era of high-performance industrial networking where microsecond-level synchronization is required.

6. ControlNet Protocol

ControlNet is another real-time communication protocol developed by Rockwell Automation. It is based on CTDMA (Concurrent Time Domain Multiple Access) technology, which allows scheduled and unscheduled data to travel together.

ControlNet is designed for applications where deterministic and high-speed communication is required, such as motion control systems, interlocking systems, and synchronized PLC operations.

Although it offers excellent real-time performance, it requires special hardware and cabling. With the growth of EtherNet/IP, the use of ControlNet is slowly declining, but it is still found in older Rockwell-based installations.

7. HART Protocol

HART stands for Highway Addressable Remote Transducer. It is widely used in the process industry for smart field instruments like pressure transmitters, flow transmitters, and control valves.

The biggest advantage of HART is that it works on the existing 4–20 mA analog signal, while also carrying digital data on the same wire. This means industries can upgrade to smart instruments without changing their old wiring.

Through HART, engineers can remotely configure devices, read diagnostics, and perform calibration checks without going into the field. HART is extremely popular in oil & gas, chemical, power, and water treatment industries.

8. PROFINET Protocol

PROFINET is the Ethernet-based successor of PROFIBUS and is also supported by Siemens and other automation manufacturers. It provides real-time and non-real-time communication over standard Ethernet.

PROFINET supports high-speed communication with PLC I/O modules, drives, robots, and automation components. It is widely used in automotive manufacturing, food processing plants, packaging systems, and discrete manufacturing units.

One advantage of PROFINET is that it easily integrates with IT systems and supports advanced diagnostics, making maintenance easier.

9. Fieldbus (General Concept)

Fieldbus is not a single protocol but a general term used for a group of industrial communication networks designed to connect field instruments directly with control systems.

Examples of Fieldbus technologies include FOUNDATION Fieldbus, PROFIBUS, and HART. These systems reduce wiring by allowing multiple instruments to connect on a single communication line. Fieldbus systems also support device diagnostics and digital communication.

Fieldbus is mainly used in process industries, where accurate measurement, stability, and intrinsic safety are critical.

10. CANopen Protocol

CANopen is a higher-level communication protocol built on the CAN bus. It is mainly used in motion control applications and compact automation systems.

CANopen provides a standardized way for devices like servo drives, encoders, sensors, and I/O modules to communicate. Because of its flexibility and low cost, it is widely used in machine automation, medical equipment, elevators, and mobile machinery.

It offers good noise immunity, reliable communication, and simple device configuration.

11. CAN Bus Protocol

The Controller Area Network (CAN) protocol was originally developed for the automotive industry but later became popular in industrial automation.

CAN bus allows multiple devices to communicate over a shared network without a central controller. It is known for its excellent error detection, strong noise immunity, and real-time performance.

In PLC systems, CAN bus is used in mobile equipment, conveyor systems, material handling machines, and outdoor automation where electrical noise is common.

12. DNP3 Protocol

DNP3 stands for Distributed Network Protocol. It is mainly used in power generation, electrical substations, and utility automation systems.

This protocol allows communication between SCADA systems and remote terminal units (RTUs) over long distances. DNP3 is designed to work reliably even in poor communication conditions. It supports time-stamped data, event logging, and secure data transmission.

Because of these features, DNP3 plays a very important role in power distribution monitoring and control.

Few more protocols as below

13. OPC UA

OPC UA (Open Platform Communications Unified Architecture) is a platform-independent industrial communication protocol used for secure and reliable data exchange between PLCs, SCADA systems, and IT networks.

It supports data encryption, authentication, and standardized information modeling, making it ideal for Industry 4.0 and IIoT applications.

OPC UA is widely used for connecting different automation systems and enabling seamless machine-to-machine communication across modern smart factories.

14. BACnet (Building Automation and Control Network)

BACnet is a communication protocol mainly used in building automation systems (BAS) for monitoring and controlling HVAC, lighting, fire alarms, and energy systems. It is an open protocol, which allows devices from different manufacturers to communicate with each other.

Key Points:

1) Widely used in HVAC and building management systems

2) Open standard with multi-vendor interoperability

3) Supports BACnet/IP (Ethernet) and BACnet MS/TP (RS-485)

4) Suitable for smart buildings, hospitals, malls, airports

5) Focused on automation of buildings, not core process industries

Ethernet APL:

Ethernet-APL (Advanced Physical Layer) is often mentioned together with industrial Ethernet protocols, but it is not a communication protocol by itself.

It is a physical layer technology that enables Ethernet-based protocols such as PROFINET, EtherNet/IP and OPC UA to be used safely in process plants and hazardous areas over two-wire cabling.

So, while it plays a key role in modern communication systems, it should be seen as an enabler for protocols, not as a protocol.

How to Choose the Right PLC Communication Protocol

The selection of a communication protocol depends on many factors such as system speed requirements, number of devices, communication distance, environmental conditions, and compatibility with existing equipment.

For example, Modbus is ideal for simple systems, while EtherCAT is suitable for high-speed motion control. HART and FOUNDATION Fieldbus are best for process industries where analog instruments dominate.

Students should also understand that in real industries, multiple protocols often work together in a single automation system.

What we learn today?

Communication protocols are the backbone of every PLC-based automation system. They allow PLCs, sensors, actuators, HMIs, and SCADA systems to exchange data accurately and reliably. Each protocol discussed in this article offers unique advantages and is designed for specific industrial needs.

From simple serial networks like Modbus and DF1 to high-speed Ethernet systems like PROFINET and EtherCAT, industrial communication has evolved rapidly. By learning these protocols, students and young engineers gain strong practical knowledge that helps them design, troubleshoot, and maintain real-world automation systems.

Understanding PLC communication is not just a subject for exams—it is a core skill for a successful career in industrial automation.

I hope you like above blog. There is no cost associated in sharing the article in your social media. Thanks for Reading !! Happy Learning