Table of Contents

ToggleAbsolute Vs Gauge Pressure: Introduction

Most technicians learn the difference between absolute vs gauge pressure early in their careers, yet these two simple terms still cause some of the most common pressure measurement mistakes in plants.

We have seen this many times during site visits, a transmitter giving “wrong” readings, operators worried about process changes and long troubleshooting sessions, only to discover that the issue was not with the instrument at all.

It was just the pressure reference.

In this article we will understand the difference between absolute vs gauge pressure and highlight the three mistakes that often lead to inaccurate readings, so you can avoid them with confidence.

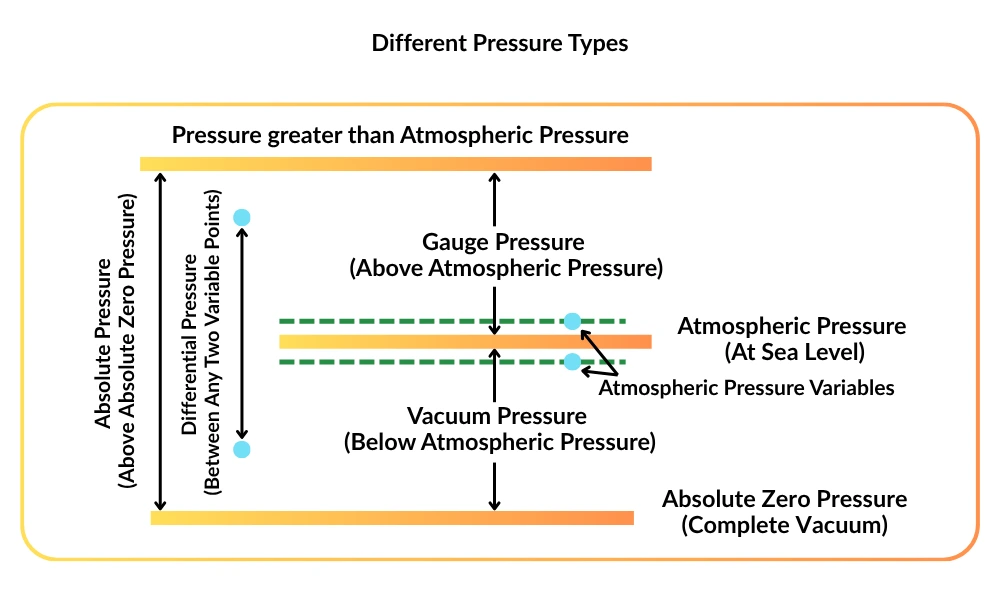

The easiest way to understand the difference between absolute vs gauge pressure is to imagine where the measurement begins.

Absolute pressure measures from a perfect vacuum (zero pressure), so it includes the effect of atmospheric pressure.

Think of it as starting from “nothing at all.”

Gauge pressure measures relative to the surrounding atmosphere, which is why a standard pressure gauge reads zero even though atmospheric pressure is actually pushing on it.

In everyday industrial applications, gauge pressure is used most often because it relates directly to what equipment experiences.

Absolute pressure is chosen when even small changes in atmospheric pressure matter, such as in vacuum systems, altitude-sensitive processes, or precise gas measurements.

Understanding this simple starting point vacuum vs atmosphere helps avoid many measurement errors.

Relationship: Absolute Vs Gauge Pressure

Absolute and gauge pressure are linked by a very simple idea:

Absolute Pressure = Gauge Pressure + Atmospheric Pressure

For example, if your car tire shows 34 PSI (gauge), the actual pressure inside the tire is 34 + 14.7 = 48.7 PSI absolute.

You can also reverse it:

Gauge Pressure = Absolute Pressure – Atmospheric Pressure.

Because atmospheric pressure changes with weather and altitude, gauge readings can change even when the true (absolute) pressure stays the same.

That is why a process running at the same absolute pressure will show a higher gauge reading in a high-altitude place like Denver, where atmospheric pressure is lower (around 12.5 PSIA).

Knowing this relationship helps you convert values correctly when accurate pressure control is important.

Avoiding Common Errors in Sensor Selection

Choosing the wrong pressure sensor may seem like a small decision, but it can create major problems in industrial systems and even lead to expensive failures.

Here are the most common mistakes technicians and engineers should avoid:

1. Mixing up gauge and absolute pressure sensors

One of the biggest errors is selecting the wrong type of pressure reference.

When gauge and absolute sensors get confused, the measurement can be off by almost 1 bar, especially in low-pressure ranges.

For example, using a gauge sensor in an absolute-pressure application adds extra errors of about ±30 mbar due to weather changes.

This error becomes even larger up to 200 mbar when moving from sea level to an altitude of 2,000 meters.

These differences can seriously affect pneumatic systems that work around 1 bar, but they barely matter in high-pressure hydraulic systems with ranges like 400 bar.

2. Ignoring environmental conditions

Pressure sensors do not work in perfect conditions.

Temperature changes can make materials expand or shrink, affecting accuracy.

High humidity may lead to condensation or corrosion on sensitive components. Vibrations introduce noise and instability in readings. Even electromagnetic fields from motors, transformers, or power cables can disturb a sensor’s output.

All these environmental effects need to be considered during selection.

3. Poor sensor placement

Where you install the sensor is just as important as the sensor you choose.

Mounting a sensor near stress points on a PCB such as screw holes or large components can distort pressure readings or even damage delicate MEMS structures.

Placing it near heat sources also creates temperature gradients that reduce accuracy.

A good practice is to keep at least 2 mm of spacing between the pressure sensor’s land area and nearby component pads or vias to ensure stable and reliable performance.

Best Practices for Accurate Pressure Measurement

Accurate pressure measurement does not happen by chance but it comes from understanding the basics, choosing the right equipment, and following good maintenance practices.

Here are the key steps to ensure your readings stay reliable.

1. Know your pressure reference

Before you measure anything, be clear whether the system requires absolute or gauge pressure.

Mixing these two references can cause errors of nearly 1 bar, especially in low-pressure applications.

For static pressure, make sure pressure taps are installed perpendicular to the flow so the reading isn’t affected by fluid movement.

For dynamic pressure measurements, follow good piping practices: keep at least 10 pipe diameters downstream from any obstruction and 2 pipe diameters upstream to get stable and accurate readings.

2. Use calibrated and certified instruments

Calibration is required for accuracy and repeatability.

Always follow the standard 4:1 Test Uncertainty Ratio, meaning your calibration equipment must be four times more accurate than the instrument being tested.

For high-accuracy pressure devices (better than 0.1% of full scale), take at least 10 readings during increasing pressure and 10 during decreasing pressure.

Always use instruments with proper certifications such as ISO 9001, which ensures quality and traceability.

3. Match the sensor to your application

Choose a pressure sensor that fits your operating conditions. The sensor’s range should be slightly above your system’s maximum pressure to avoid overload.

Ensure the sensing material is compatible with your process media, stainless steel and ceramic are common choices for harsh conditions.

Also consider temperature, humidity, and electromagnetic interference.

Finally, make sure the sensor’s output signal (e.g., 4–20 mA, voltage, digital) matches your control system requirements.

4. Inspect and maintain sensors regularly

Routine inspection is key to long-term accuracy.

Depending on how critical the application is, check sensors every 6 to 12 months.

Look for signs of corrosion, damage, or loose connections. Clean sensors carefully and avoid chemicals that may harm sensitive parts.

Keep proper maintenance records they help you spot trends, schedule predictive maintenance, and reduce unexpected system downtime.

What we learn today?

Understanding the difference between absolute and gauge pressure is the first step toward achieving accurate and reliable measurements.

Choosing the wrong reference can create errors close to 1 bar, which can be serious in sensitive applications.

Factors like weather and altitude also affect gauge readings, making the correct reference even more important.

Accurate pressure measurement takes more than just installing a sensor it requires the right sensor type, proper calibration, correct placement, and regular maintenance.

Clearly identifying whether you need absolute or gauge pressure when specifying a sensor will greatly improve system performance. With these best practices in place, your pressure measurement setup will deliver dependable, long-lasting accuracy.

I hope you like above blog. There is no cost associated in sharing the article in your social media. Thanks for Reading !! Happy Learning