Table of Contents

ToggleIf you are studying instrumentation or already working in the field, I am sure you have heard these two terms many times: static pressure and differential pressure.

At first, both sound almost the same because both deal with pressure. But once you start working with real plant systems, you quickly realize that their applications and purposes are completely different.

In this article, I am going to explain static pressure vs differential pressure in the simplest way.

What Is Pressure? (Quick and Simple)

In simple words, pressure is the force exerted by a fluid on a surface. Whenever a liquid or gas is trapped inside a pipe, tank, or vessel, it creates pressure.

This pressure is commonly measured in bar, psi, Pascal, or kg/cm².

Now, depending on how and where we measure this pressure, we classify it as:

- Static pressure

- Differential pressure

Understanding this distinction is extremely important for correct instrument selection and correct measurement.

What Is Static Pressure?

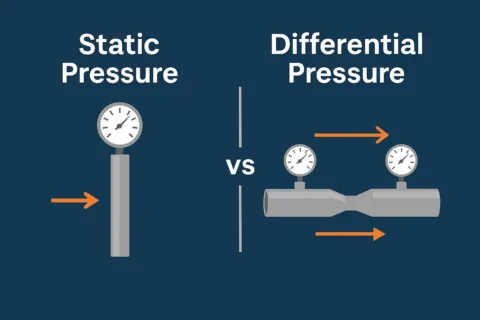

Static pressure is the pressure measured at a single point in a system. It tells you how much pressure exists exactly at that location, without comparing it with any other point.

Let me give you a very simple real-life example.

Imagine a water tank on your building terrace. The pressure at the bottom outlet depends on how high the water level is inside the tank. That pressure at the outlet is static pressure. You are measuring pressure at only one location.

Another common example is the pressure inside a compressed air receiver. The value shown on the pressure gauge mounted on that tank is also static pressure.

In industrial plants, static pressure is measured in pipelines, storage vessels, boilers, compressors, hydraulic systems, and at the discharge of pumps.

The main purpose of static pressure measurement is safety and basic system monitoring.

Static pressure is measured using pressure gauges, pressure transmitters, and pressure switches. These instruments have only one pressure port, because they sense pressure at a single point.

Static Pressure Formula in Liquid Systems

In liquid systems, static pressure due to a liquid column depends on liquid density and height.

The relationship is given by a very simple and important formula:

P = ρgh

Where:

P = static pressure

ρ = density of the liquid

g = gravitational acceleration

h = height of the liquid column

This formula clearly tells us that as the liquid level increases, static pressure at the bottom increases. That is why tall tanks always have higher bottom pressure compared to short tanks.

What Is Differential Pressure?

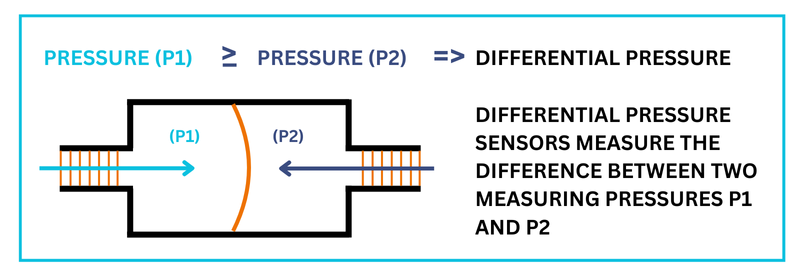

Differential pressure, usually written as ΔP, is the difference between two pressures measured at two different points in a system. Instead of measuring only one pressure, we compare two pressures and calculate the difference.

The basic formula for differential pressure is:

ΔP = P₁ − P₂

Where:

P₁ = pressure at point 1

P₂ = pressure at point 2

For example, if the pressure at the inlet of a filter is 6 bar and the pressure at the outlet is 4 bar, then:

ΔP = 6 − 4 = 2 bar

This 2 bar is the differential pressure across the filter. It tells us how much pressure is being lost due to flow resistance.

A very common daily-life example of differential pressure is an air filter. When the filter is clean, the pressure difference is small. As dirt starts blocking the filter, the pressure difference increases. This increase in ΔP directly indicates clogging.

In industries, differential pressure is widely used for flow measurement, level measurement in pressurized tanks, filter condition monitoring, and heat exchanger performance monitoring.

Differential pressure is measured using DP transmitters, DP gauges, or DP switches. These instruments always have two pressure ports a high-pressure side and a low-pressure side.

Static Pressure vs Differential Pressure – Core Difference

The simplest way to understand the difference is this:

Static pressure answers:

“How much pressure is present at this one point right now?”

Differential pressure answers:

“How much pressure difference exists between these two points?”

Static pressure uses only one tapping point. Differential pressure always uses two tapping points. Static pressure is mainly used for monitoring and protection, while differential pressure is mainly used for measurement and performance evaluation.

Flow Measurement Using Differential Pressure (With Formula)

In differential pressure flow measurement, the flow rate is related to the square root of differential pressure. The basic relationship can be written as:

Flow ∝ √(ΔP)

This means that the flow is proportional to the square root of the differential pressure.

In simple words, if the differential pressure increases four times, the flow will only increase two times.

That is why accurate DP measurement and proper calibration are extremely important in flow applications using orifice plates, venturi tubes, and flow nozzles.

Level Measurement Using Differential Pressure (With Formula)

In pressurized tanks, liquid level is measured using differential pressure based on the same hydrostatic principle:

ΔP = ρgh

Here, the differential pressure between the bottom and the top of the tank is directly proportional to the liquid height. If the liquid density is known, the level can be calculated very accurately from the measured differential pressure. This method is widely used in chemical, oil and gas, and power industries.

You can read my article: DP Transmitter Level Measurement in detail.

Static Pressure Transmitter vs Differential Pressure Transmitter

A static pressure transmitter has only one pressure port and measures pressure at one location. It converts this pressure into a standard electrical signal, usually 4–20 mA, which is sent to the control system for monitoring and alarms.

A differential pressure transmitter, on the other hand, has two pressure ports=> high and low. It continuously measures the difference between these two pressures and sends a corresponding output signal. DP transmitters are mainly used for flow, level, and filter applications.

Selection of the wrong transmitter is one of the most common causes of incorrect measurement in industrial plants.

How to Decide: Static or Differential?

Here is a very simple decision rule you can always follow:

1) If you want pressure at one point, use static pressure measurement.

2) If you want pressure loss, flow, level, or blockage information, use differential pressure measurement.

If you just remember this rule, your instrument selection will almost always be correct.

What we learn today?

If you are still learning instrumentation, don’t worry if this topic felt difficult at first. Every experienced engineer once struggled with these same concepts. With time, practice, and site exposure, everything becomes clear.

For now, just remember this:

1) Static pressure is pressure at one point.

2) Differential pressure is the pressure difference between two points.

Once this concept becomes clear in your mind, flow measurement, level measurement, and troubleshooting will automatically start making much more sense to you.

I hope you like above blog. There is no cost associated in sharing the article in your social media. Thanks for Reading !! Happy Learning