Table of Contents

ToggleIndustrial processes often involve mixing, blending, or combining different materials. These materials must be added in the right proportion to produce a consistent and high-quality output.

If the proportion changes even slightly, the product quality drops, energy consumption increases, or sometimes the process becomes unsafe.

One of the easiest and most reliable ways to maintain these proportions is through a technique called ratio control.

In this article, we will understand ratio control in a very simple way so that even a beginner in instrumentation can understand the topic confidently.

Understanding the Meaning of Ratio Control

Ratio control is a method where the flow of one material automatically adjusts itself based on the flow of another material. The goal is to maintain a constant proportion between two streams. Whenever the primary flow changes, the secondary flow instantly follows it so the ratio remains the same.

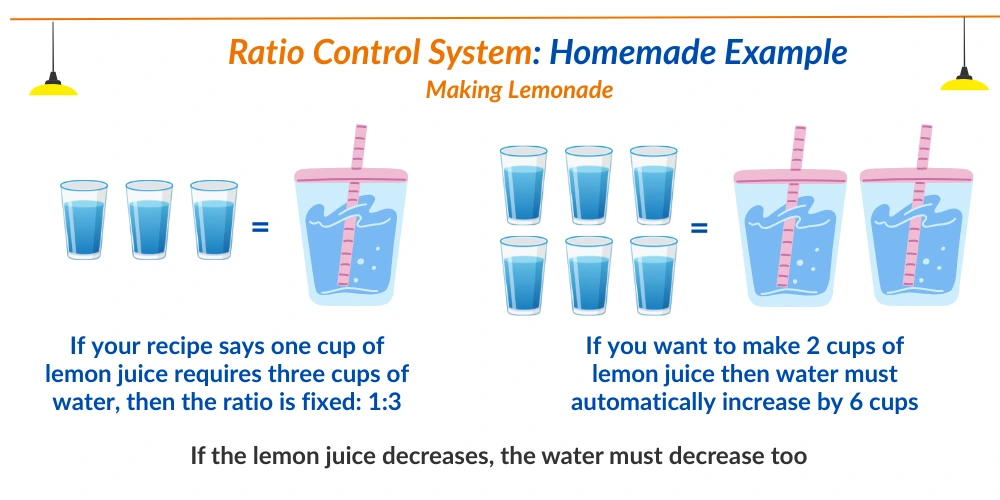

A simple way to imagine this is by thinking about making lemonade.

If your recipe says one cup of lemon juice requires three cups of water, then the ratio is fixed: 1:3. If you decide to make more lemonade and the lemon juice becomes two cups, the water must automatically become six.

If the lemon juice decreases, the water must decrease too.

This is exactly how ratio control behaves in industrial systems only the measurement and correction happen using sensors and controllers instead of human hands.

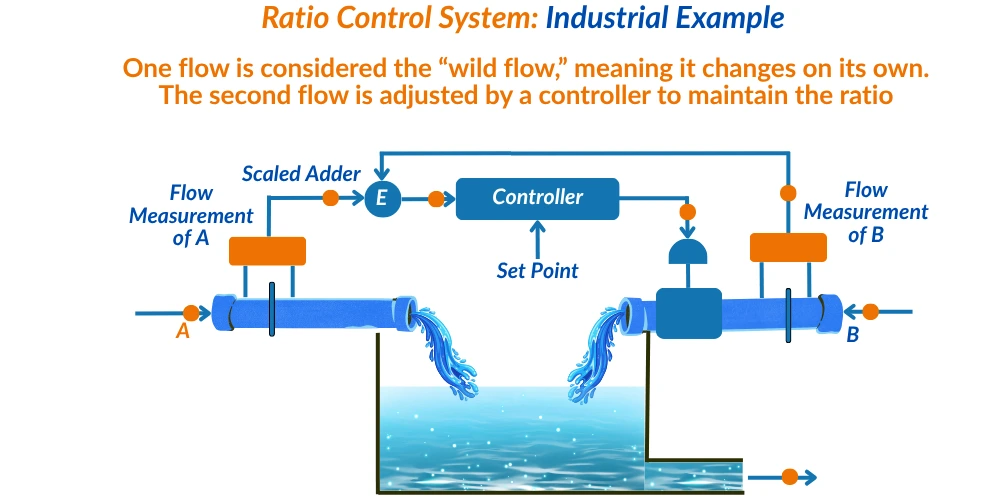

In technical terms, one flow is considered the “wild flow,” meaning it changes on its own. The second flow is adjusted by a controller to maintain the ratio. That is all there is to it.

Why Do Industries Use Ratio Control?

Industrial processes depend heavily on maintaining uniformity. Even a small change in the proportion of chemicals, air, water, fuel, or additives can ruin the final product. Ratio control prevents these problems by ensuring that the relationship between the two materials remains steady.

The main reason industries prefer ratio control is because it works even when the primary flow keeps fluctuating. For example, if the water flow in a pipeline suddenly increases, a chlorine dosing system using ratio control will immediately add more chlorine to match the new water flow. Because of this automatic adjustment, the process continues smoothly without affecting quality or safety.

Ratio control improves product consistency, reduces waste, stabilizes chemical reactions, and ensures safe operation. It also reduces the need for manual monitoring and adjustments, which is important in large or fully automated plants.

How Ratio Control Works?

To understand how ratio control works, imagine that we have two streams: Stream A and Stream B.

Stream A is allowed to vary freely. It might increase or decrease based on external conditions. This is why we call it the wild flow. A flow transmitter measures this flow continuously.

Now, the operator sets a fixed ratio, such as 1:5 or 1:10. This is fed into a ratio station or directly into the controller. The controller then multiplies the measured flow of Stream A with the ratio and calculates how much Stream B must be.

A second controller and a control valve (or pump) work together to adjust Stream B’s flow based on this calculated value. As Stream A changes, Stream B keeps following it.

For example, imagine Stream A is flowing at 100 liters per minute, and the chosen ratio is 1:4. Then Stream B needs to be 400 liters per minute. If Stream A increases to 120 liters per minute, Stream B automatically becomes 480 liters per minute. If Stream A decreases, Stream B decreases too. The proportional relationship is always maintained.

In above setup, the ratio between the two reactants must be maintained. One reactant’s flow rate is measured but allowed to vary freely and is not controlled.

The second reactant’s flow rate is then adjusted based on this value to maintain the required ratio.

The flow of reactant A is measured and scaled appropriately, then compared with the flow measurement of reactant B.

The controller uses this combined signal to adjust the control valve on the reactant B line, ensuring the correct ratio is achieved.

Importance of analyzer-based feedback in complex ratio control applications

In applications where the correct mixture must be verified through product quality such as pH control in neutralization or O₂/CO₂ ratio control in combustion, a process analyzer is integrated into the ratio control loop.

This allows the control system not only to maintain a mathematical ratio but also to ensure that the process result (quality parameter) stays within limits.

Example:

- Neutralization process using acid & caustic → inline pH meter provides feedback

- Combustion control using fuel & air → O₂ or CO₂ analyzer ensures efficient burning

This approach creates a closed-loop ratio control system that dynamically corrects disturbances and variations in material properties.

Where Ratio Control Is Used in Industry?

Ratio control is found almost everywhere in process industries because maintaining proportions is a basic requirement in many operations. Let us look at the most common areas where ratio control plays a key role.

1. Fuel–Air Control in Boilers and Furnaces

Boilers require the right amount of air to burn fuel efficiently. If air is too low, incomplete combustion happens. If air is too high, heat escapes through the flue, lowering efficiency. A fixed air-to-fuel ratio prevents these issues. Both flows constantly adjust based on each other, ensuring clean burning and stable furnace operation.

2. Chemical Dosing in Reactors

Chemical reactions depend on correct stoichiometric proportions. Whether it is acid dilution, resin-hardener mixing, catalyst addition, or polymer blending, ratio control ensures that the reactants always follow the required mixing proportion. This avoids poor reaction rates and prevents batch rejection.

3. Chlorine Dosing in Water Treatment Plants

Water flow in treatment plants keeps changing, but chlorine dosage must always match the water volume. Ratio control automatically increases or decreases chlorine injection based on water flow, ensuring proper disinfection and safe water quality.

4. Food and Beverage Manufacturing

Most beverages, dairy products, and liquid foods require stable and repeatable recipes. Soft drinks are produced by maintaining a fixed syrup-to-water ratio. Ice-cream mixes, juices, and flavored milk also rely on accurate blending. Ratio control makes sure the taste and texture remain the same in every batch.

5. Gas Mixing Systems

Some industrial furnaces mix two or more gases, such as natural gas with hydrogen or nitrogen. Ratio control ensures that the mixture always stays in the correct proportion, which is important for flame temperature, safety, and energy efficiency.

6. Paints, Dyes, and Coatings Production

Paints and dyes need precise proportions of pigments, solvents, additives, and resins. Even a small change in ratio can affect color shade, drying time, thickness, or chemical stability. Ratio control helps the mixing process achieve exact formulation every time.

7. Cement and Concrete Batching

Concrete strength depends on the right proportion of cement, sand, aggregate, and water. Modern batching plants use ratio control to maintain these proportions automatically as materials flow through conveyors and feeders.

8. Spray Dryers and Powder Systems

Spray dryers require proper balance between feed flow, hot air flow, and steam. If the proportion is not maintained, powder can burn or remain wet. Ratio control ensures each stream follows the other, creating a stable drying environment.

Advantages of Ratio Control

Although ratio control is simple in concept, it delivers strong benefits for process stability and product consistency.

One major advantage is that it automatically compensates for fluctuations in the primary flow. This leads to stable mixing and reduces operator workload.

It also minimizes waste because materials are always added in the correct proportion. Finally, ratio control improves safety, especially in systems involving fuel or chemicals, because the flows stay balanced even under changing process conditions.

Limitations of Ratio Control

Ratio control has a few limitations.

It depends heavily on accurate flow measurement. If the flow transmitter on either stream gives an incorrect reading, the entire ratio will shift.

It also may not perform well when both streams change rapidly and unpredictably. In such cases, more advanced control strategies may be needed.

Finally, some processes require different ratios at different conditions, and a fixed ratio system may not be flexible enough unless supervisory logic is added.

Frequently Asked Questions: Ratio Control

1. Why is ratio control needed in industry?

Because it keeps two or more materials in a fixed proportion, which is essential for product quality and safety.

2. Does ratio control need highly accurate sensors?

Yes. A flow transmitter with poor accuracy will disturb the proportion and cause variations.

3. Is ratio control difficult to implement?

Not really. It is one of the simplest control strategies and is widely used in PLC and DCS systems.

4. What is the difference between ratio control and feedforward control?

Ratio control maintains proportion between two flows, while feedforward control corrects for disturbances before they affect the process.

5. Can ratio control work with more than two streams?

Yes, multi-stream ratio control is common in beverage, chemical, and fuel blending systems.

I hope you like above blog. There is no cost associated in sharing the article in your social media. Thanks for Reading !! Happy Learning

2 Comments