Table of Contents

ToggleBoiler Drum Level Control – Introduction

The main purpose of boiler drum level control is to bring the water level in the drum to the correct point during boiler start-up and to keep it steady when the steam load changes.

If the water level drops too low, parts of the boiler tubes can be exposed and overheat, causing serious damage.

On the other hand, if the level becomes too high, water can mix with the steam. This reduces boiler efficiency and can allow moisture to enter the process or turbine which is harmful.

Main Functions of the Drum Level Controller

The boiler drum level controller performs several key functions to keep the system running safely and efficiently:

a) Allows the operator to adjust the drum level setpoint

b) Compensates for the shrink and swell effects that occur due to steam load changes

c) Automatically maintains the correct drum level

d) Enables manual control of the feedwater valve when needed

e) Provides smooth switching between automatic and manual control modes

f) Shows the current drum level and steam flow rate

g) Displays the feedwater valve position and flow rate

h) Gives alarms when the drum level goes too high or too low

Types of Boiler Drum Level Control

There are three main types of boiler drum level control systems used in industries:

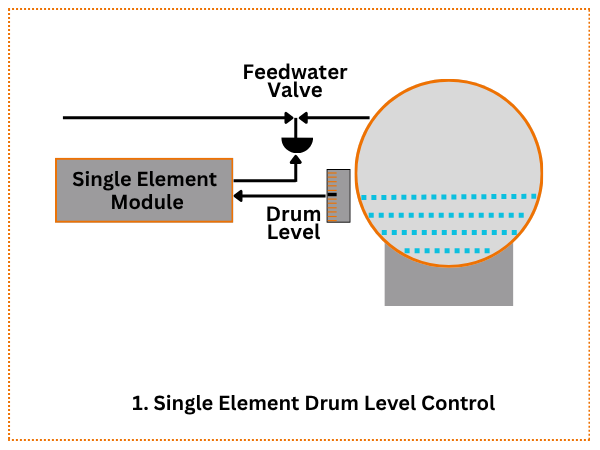

1. Single-element drum level control

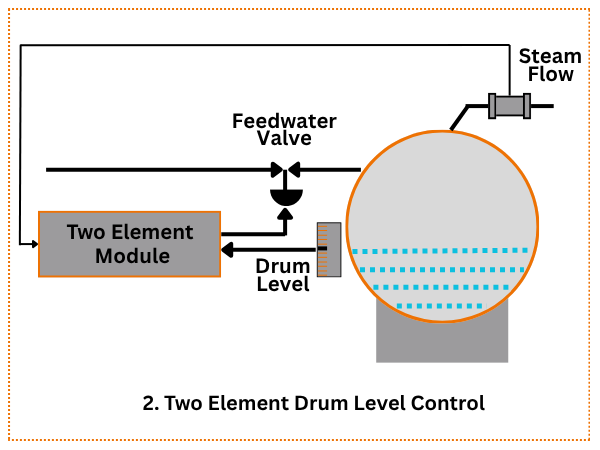

2. Two-element drum level control

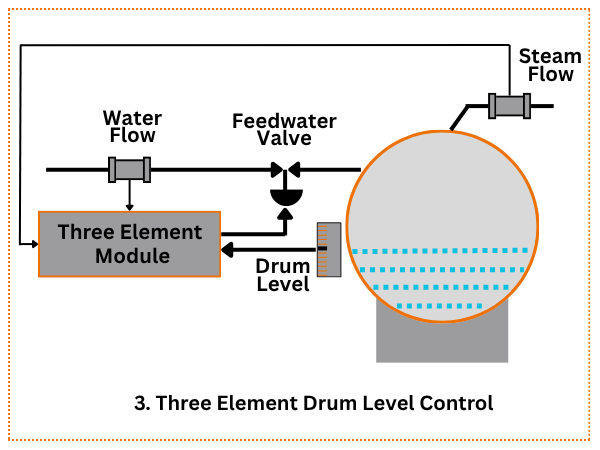

3. Three-element drum level control

Single Element Boiler Drum Level Control

Single Element Boiler Drum Level Control is the simplest type of drum level control system, but it’s also the least effective in handling load changes.

In this method, a signal from the drum level transmitter (known as the process variable or PV) is sent to the controller. The controller compares this signal to a preset setpoint. The difference between them is called the deviation.

The controller then reacts to this deviation by sending a proportional output signal to the boiler feedwater valve. Based on this signal, the valve adjusts the amount of feedwater entering the boiler drum to maintain the desired level.

Key Points:

1) Requires only one analog input (drum level) and one analog output (feedwater valve).

2) Suitable only for single boiler and single feed pump systems that have stable operating loads.

3) Not ideal for systems with changing steam demand, as it does not account for steam or feedwater flow.

4) Can lead to poor control performance due to the shrink and swell effect in the boiler drum

Two Element Boiler Drum Level Control

Two Element Boiler Drum Level Control is an improved method compared to the single-element system. It is most suitable for single-drum boilers where the feedwater pressure remains constant.

This system uses two key inputs, or “elements,” to maintain the correct drum level:

1. Level Element

The first element is the drum level signal (process variable or PV) received from the level transmitter. This signal is compared with a setpoint to find the deviation. The controller then acts on this deviation to adjust the feedwater flow proportionally, keeping the water level close to the desired value.

2. Steam Flow Element

The second element measures the steam flow rate (corrected for density). This acts as a feedforward signal, helping the system quickly adjust feedwater flow when steam demand changes.

If there’s any imbalance between the amount of steam leaving and the feedwater entering the drum, the level controller automatically corrects it. Such imbalances can occur due to:

a) Changes in blowdown rate caused by dissolved solids

b) Variations in feedwater pressure

c) Steam leaks in the

Key Points:

1) Provides better drum level stability than single-element control.

2) Uses steam flow as a feedforward input, ensuring faster response to load changes.

3) Works best for single boiler and single feed pump systems where feedwater pressure is steady.

Three Element Boiler Drum Level Control

Three Element Boiler Drum Level Control is the most advanced and reliable method used in boiler systems. It is especially useful in plants with multiple boilers and feedwater pumps, or where feedwater pressure and flow vary frequently.

This system uses three main inputs (or elements) to maintain accurate drum level control.

1) Level Element & Steam Flow Element

These two elements work together to correct unmeasured changes or disturbances in the system, such as:

a) Boiler blowdown

b) Leaks in boiler or superheater tubes

They help stabilize the drum level by constantly monitoring both the water level and the steam output.

2) Feedwater Flow Element

The third element measures the feedwater flow rate. It responds quickly to changes in water demand that can occur due to:

a) Steam flow rate variations (feedforward action)

b) Fluctuations in feedwater pressure or flow

For the best accuracy, both steam flow and feedwater flow readings should be corrected for density changes.

Key Points:

1) Offers precise and stable drum level control, even with fluctuating steam loads.

2) Ideal for systems with varying feedwater pressure or flow.

3) Requires a more advanced control system and an extra input for measuring feedwater flow.

What we learn today?

Boiler drum level control keeps the water in the boiler at the right level for safe and efficient operation.

It prevents damage from low water and moisture problems from high water.

Single, two, and three-element systems offer increasing accuracy depending on load and pressure changes.

I hope you like above blog. There is no cost associated in sharing the article in your social media. Thanks for reading!! Happy Learning!!