A Distributed Control System (DCS) is a computer based system used to control processes in manufacturing plants or industries.

The term “distributed” means that control is shared across multiple operators, instead of depending on just one central unit.

This way, if one operator fails, the whole system does not stop working. All the parts are still connected and can be monitored through a central computer, but the actual control is spread out to different supervisory computers.

Table of Contents

ToggleDistributed Control System (DCS) Block Diagram

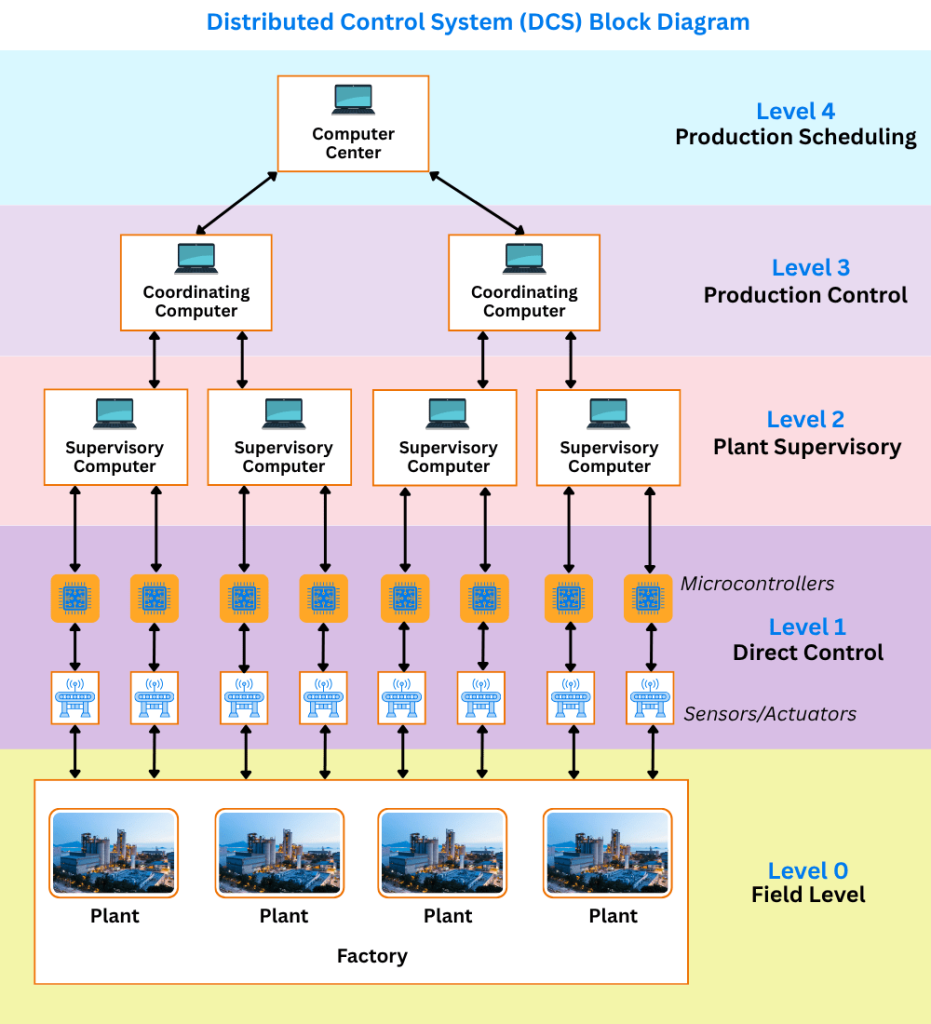

Please see below the block diagram of Distributed Control System (DCS).

The structure of Distributed Control System (DCS) is classified into different levels.

Level 0 – Field Level (sensors, transducers, actuators)

Level 1 – Direct Control (hardware connecting field devices to computers)

Level 2 – Plant Supervisory (operator control)

Level 3 – Production Control (Production monitoring and co-ordination)

Level 4 – Production Scheduling (Management and Production scheduling)

Layers of a Distributed Control System (DCS)

Level 0 – Field Devices

This is the ground level where all physical devices are located. It includes sensors, transducers, and actuators that directly interact with the real world.

- Sensors: Devices that detect physical changes such as temperature, pressure, or flow. For example, a temperature sensor measures heat changes. They act like the input devices of the system, helping DCS collect real-time data from the plant.

- Transducers: Devices that convert one form of energy into another. An input transducer converts physical signals (like pressure) into electrical signals, while an output transducer does the opposite (like a speaker creating sound for an alarm). Many sensors are also a type of input transducer.

- Actuators: Devices that take action when given an electrical signal. They physically move or adjust equipment such as valves or levers. For example, a solenoid valve controls the flow of fluids.

Level 1 – Controllers

This level consists of controllers like microcontrollers, I/O racks, and other circuits (converter, driver, or controller circuits). All the sensors, actuators, and transducers are connected here. These devices receive signals from higher supervisory computers and directly control the field devices.

Level 2 – Supervisory Computers

At this level, operators monitor and control the process. Data from field devices is collected here, and operators can directly interact with and control equipment through these computers. In a plant, this is the level where workers keep an eye on operations and make adjustments when needed.

Level 3 – Production Control

This level has coordinating computers. It doesn’t directly control field devices but focuses on managing and monitoring the overall production process. It ensures that everything is running according to plan and on schedule.

Level 4 – Plant Management

This is the topmost layer, where the production schedule is created and the entire operation is supervised. It deals more with planning and management rather than direct control of devices.

Characteristics of Distributed Control System (DCS)

A Distributed Control System (DCS) has the following key features:

- Control functions are divided into smaller subsystems, which work semi-independently. These subsystems are connected through a high-speed communication bus and handle tasks like data acquisition, process control, and data presentation.

- It allows automation of manufacturing processes by using advanced control strategies.

- It organizes all devices and processes into a well-structured system.

- Provides strong system protection and reliability.

Advantages of Distributed Control System (DCS)

The benefits of using a DCS include:

- Reduced engineering time during design and implementation.

- Control functions are spread across multiple CPUs (Field Control Stations). This means if one station fails, the rest of the plant continues running.

- Minimal troubleshooting is needed, and maintenance is easier.

- Interlocks can be generated or modified quickly and flexibly.

- Process information can be displayed to operators in multiple formats for better understanding.

Applications of Distributed Control System (DCS)

DCS is widely used in industries and processes such as:

- Chemical, petrochemical, nuclear, and refinery plants

- Environmental control systems

- Water supply, treatment, and sewage management

- Food and food processing industries

- Metal and mining industries

- Automobile manufacturing plants

What Makes the DCS so Important?

To understand the importance of a Distributed Control System (DCS), let us compare two plants.

First, take a small municipal wastewater treatment plant with only about a dozen control loops. Here, the engineering staff can easily monitor and manage the system since there are only a few controllers.

Now compare that to a large refinery with nearly 10,000 fast-changing and interconnected control loops. In this case, coordinating control without a DCS would be extremely difficult and overwhelming.

Traditionally, DCS was the preferred choice for safe and efficient control across an entire plant. However, as technology has advanced, Programmable Logic Controllers (PLCs) have also become more powerful.

Today, the line between DCS and PLC is becoming less clear, and in the future, these two systems may function almost interchangeably.

I hope you like above blog. There is no cost associated in sharing the article in your social media. Thanks for reading!! Happy Learning!!