Table of Contents

ToggleWhat is Capillary Tubing in Pressure Measurement?

Capillary tubing is often used in industrial pressure measurement systems to connect pressure instruments like gauges or transmitters to the process.

But why use capillary tubing instead of directly mounting the instrument to the pipe or tank?

There are many practical reasons:

This is where capillary tubing helps. It acts like a small pipe filled with special oil, carrying pressure from the process to the instrument. But while capillary tubing gives us convenience, it also introduces some effects that can reduce measurement accuracy if not properly understood.

In this article, we will explain below three common issues using capillary tubing in pressure measurements

Temperature Effect

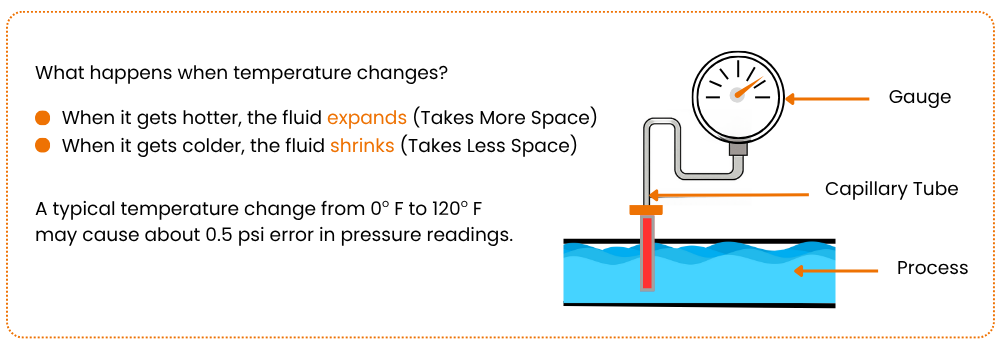

Capillary tubes are filled with a liquid called fill fluid, usually silicone oil. This fluid is sealed inside the system from the process side (via an isolator ring) to the gauge or transmitter. When temperature changes, this fluid expands or shrinks, just like most liquids do.

What happens when temperature changes?

👉 When it gets hotter, the fluid expands (takes more space).

👉 When it gets colder, the fluid shrinks (takes less space).

Since the fluid is trapped in a closed system, even a small expansion can push against the sensing element (diaphragm or bourdon tube). This creates a false pressure signal, even if the real process pressure has not changed.

How much error?

According to my experience:

A typical temperature change from 0°F to 120°F may cause about 0.5 psi error in the pressure reading.

However, if the isolator ring has a rubber sleeve, it helps absorb the expansion better than a metal seal. This means less error.

Tip: Check if your diaphragm seal is rubber or metal – it affects temperature error.

Elevation Effect (Height Difference)

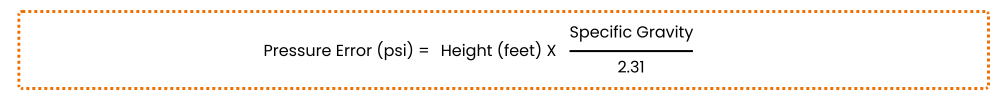

The fill fluid inside the tube behaves like water in a straw. Its weight causes a static pressure that either adds to or subtracts from the actual pressure.

Let us understand both cases:

1️⃣ Case 1: Gauge is ABOVE the process (Isolator Ring)

1) The fill fluid flows down toward the process.

2) Its weight pulls down, reducing pressure at the gauge.

3) So, the gauge reads lower than the actual pressure.

4) This is a positive elevation error in the formula.

2️⃣ Case 2: Gauge is BELOW the process (Isolator Ring)

1) The fill fluid flows down into the gauge.

2) Its weight adds extra pressure to what the gauge sees.

3) So, the gauge reads higher than the actual pressure.

4) This is a negative elevation error in the formula.

Elevation Error Formula

So, even a few feet of height difference can cause a noticeable pressure error.

Can this error be fixed?

Yes! If the gauge or transmitter has a zero adjust screw, you can simply:

Adjust the zero after installation.

This cancels out the elevation effect.

Tip: Always set the final zero after mounting the instrument — not before!

Response Time (Delay in Reading)

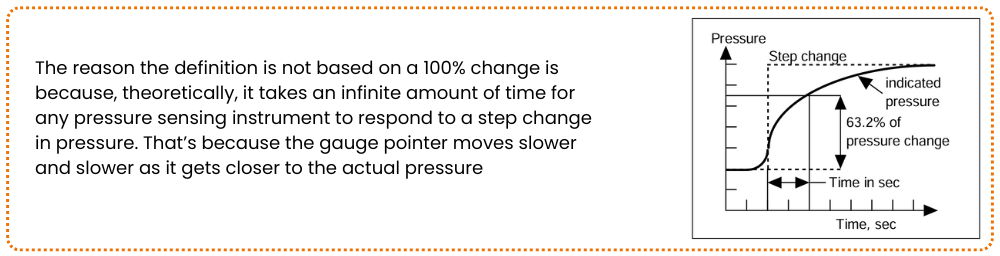

When you use a capillary tube, you will notice the gauge or transmitter does not react instantly to pressure changes. This is called response lag.

Response time is defined as the time, in seconds, for the pressure-sensing instrument to register 63.2% of a step

change in pressure.

Why does this delay happen?

There are four main reasons:

1) Longer capillary tubes take more time to transfer pressure.

2) Narrower tubes create more resistance to fluid movement.

3) Thicker fluid (higher viscosity) flows slower, especially at low temperatures.

4) Larger internal volume (control volume) inside the gauge also slows response.

Control Volume – What is it?

The control volume is the amount of fluid movement needed to shift the sensing element (like a diaphragm or bourdon tube) from 0% to 100% of scale.

1) High-pressure gauges (e.g., 100 psi) have small control volumes.

2) Low-pressure gauges (e.g., 15 psi) have larger control volumes and they respond slower.

Electronic transmitters have much smaller control volumes than mechanical gauges, so they respond faster.

How is response time measured?

Response time is defined as the time taken for the instrument to show 63.2% of a sudden pressure change (called a step change).

Example: If you apply a sudden pressure, and it takes 2 seconds for the gauge to move 63.2% of the way — that is the response time.

This 63.2% value is used because theoretically, it takes infinite time to reach exactly 100% in physical systems (like a bouncing ball that never fully stops).

Tip: In cold weather, fill fluids get thicker, so gauges respond even slower. That is why temperature and viscosity matter!

I hope you like above blog. There is no cost associated in sharing the article in your social media. Thanks for reading!! Happy Learning!!